5083 Marine Aluminum Fencing and Railings for Coastal Marine Safety Solutions

When it comes to enhancing safety and durability along coastal infrastructure, selecting the right materials for fencing and railings is paramount. Among the most trusted choices is 5083 marine aluminum, renowned for its extraordinary corrosion resistance, strength, and longevity in harsh seawater environments.

Why 5083 Marine Aluminum?

Marine fencing and railings around coastal environments—including ports, marinas, waterfront promenades, and offshore platforms—are continuously exposed to saltwater, high humidity, UV radiation, and variable mechanical stresses. Traditional materials such as steel or wood often suffer rapid degradation, requiring frequent maintenance and replacement.

The 5083 aluminum alloy is a premium choice designed specifically for such extreme conditions. This alloy combines 4% to 4.9% magnesium with other trace elements, imparting exceptional corrosion resistance, high tensile strength, and lightweight properties.

Technical Properties and Chemical Composition

| Element | 5083 Alloy Composition (Weight %) |

|---|---|

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | Max 0.4 |

| Silicon (Si) | Max 0.4 |

| Copper (Cu) | Max 0.1 |

| Zinc (Zn) | Max 0.25 |

| Aluminum (Al) | Remainder (~95%) |

Alloy Tempering and Mechanical Parameters

5083 alloy is typically supplied in two major temper conditions suitable for structural marine applications:

- H111 temper: Strain-hardened and partially annealed, with moderate strength and good ductility.

- H116 temper: Strain-hardened with exceptional corrosion resistance, commonly used in marine environments due to stress corrosion cracking resistance.

| Parameter | Value (Approximate) |

|---|---|

| Ultimate Tensile Strength | 290 – 350 MPa |

| Yield Strength | 145 – 215 MPa |

| Elongation at Break | >12% |

| Density | 2.66 g/cm³ |

| Thermal Conductivity | 121 W/m·K |

Functions and Benefits in Marine Fencing and Railings

1. Superior Corrosion Resistance

Aluminum’s natural oxide layer creates an effective barrier that protects 5083 alloy against corrosive saltwater, including crevice and pitting corrosion. The chromium and manganese additions further stabilize this oxide layer, providing exceptional longevity without the need for costly coatings.

2. High Mechanical Strength for Safety

Safety-critical fencing and railings must endure impact forces from human traffic, environmental loads (e.g., high winds, wave spray), and equipment contact. 5083's solid yield and tensile strength ensure structural integrity and resistance to deformation over time.

3. Lightweight Construction for Ease of Installation

Compared to stainless steel or galvanized steel, 5083 marine aluminum’s low density drastically reduces weight. This improves installation efficiency, lowers transportation costs, and facilitates modular design without compromising strength.

4. Low Maintenance Requirements

Unlike traditional materials that require repainting or rust treatment, 5083 aluminum fencing and railings retain their appearance and performance over years with minimal upkeep – an important factor for cost-effective marine viaduct, pier, and shoreline protection solutions.

Implementation Standards and Best Practices

For critical coastal marine infrastructure, fencing andrailings constructed from 5083 aluminum should adhere to recognized engineering standards such as:

- Aluminum Design Manual (Railway & Marine Parts)

- ASTM B209 for aluminum sheet and plate specifications,

- NSF/ANSI 61 for potable water contact if necessary,

- Local coastal building codes for loads including wind and impact.

Furthermore, welding must be executed using appropriate procedures for marine aluminum alloy (mostly GTAW/MIG processes employing ER5356/ER5554 filler rods) with pre-weld heat treatment and stress relieving when recommended.

All fasteners and connectors must be fabricated from corrosion-resistant marine-grade stainless steel (often grade 316 or higher) ensuring long-term galvanic compatibility to prevent galvanic corrosion.

Practical Applications on the Coastline

- Seaside boardwalks and promenades: Durable, impact-resistant railings ensure pedestrian safety with unobstructed ocean views.

- Marine slip docks and piers: Protective fencing that withstands salty spray and constant water flux without degrading.

- Shipyards and Foundries: Restrict unauthorized access while enduring airborne salt and mechanical vibration.

- Offshore platforms: Resist fatigue inflicted by harsh sea winds and maintain structural order during complex operations.

- Lighthouses & Harbor Installations: Critical high-corrosion risk areas require ultra-resistant barriers constructed with 5083 aluminum.

Related Products

Marine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

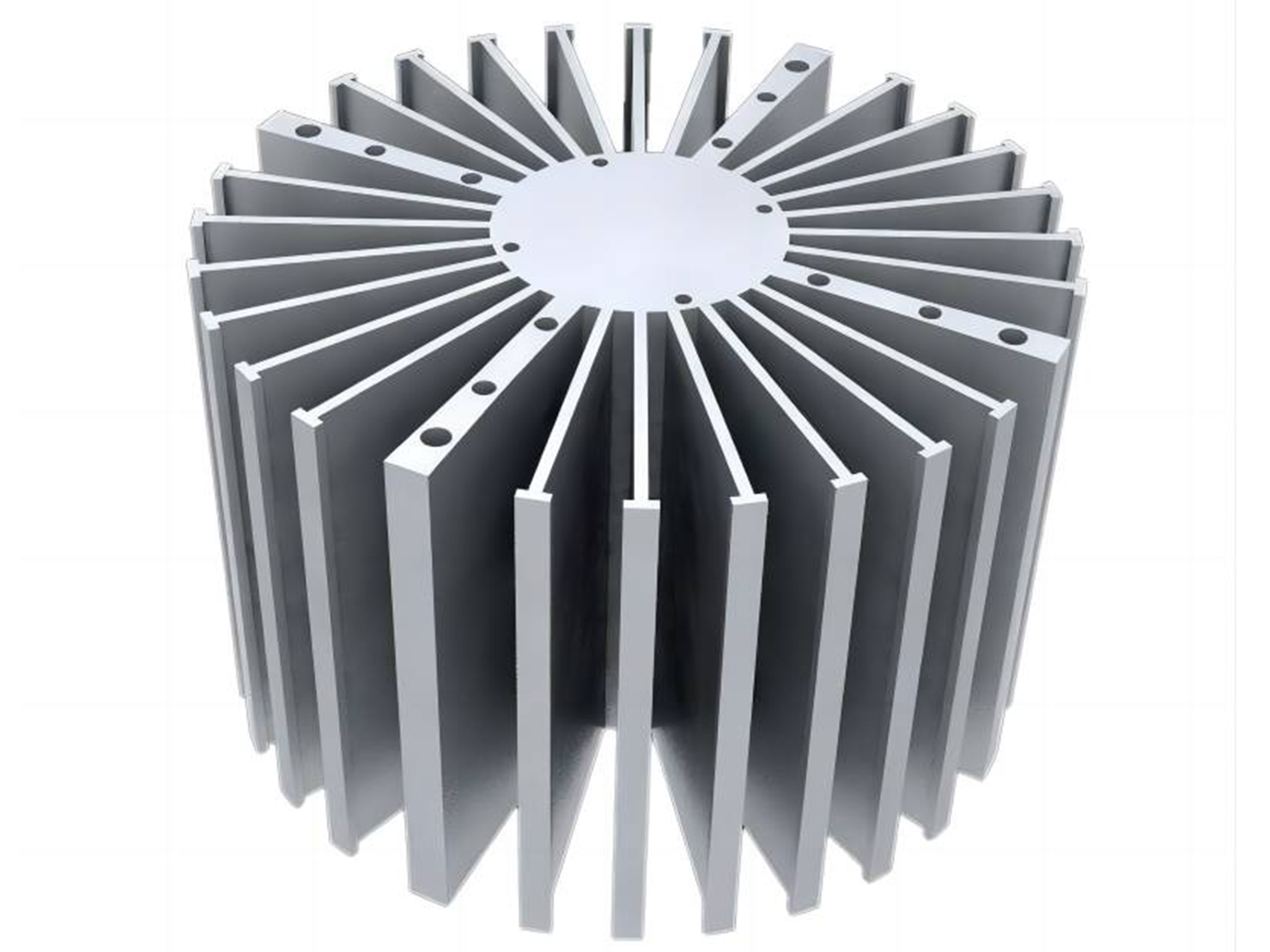

View DetailsMarine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsRelated Blog

5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Frame Reinforcements

When it comes to offshore vessel deck frame reinforcements, the choice of materials is critical for durability, strength, and corrosion resistance. Among the myriad of options.

View Details5083 Marine Aluminum Fencing and Railings for Coastal Marine Safety Solutions

When it comes to enhancing safety and durability along coastal infrastructure, selecting the right materials for fencing and railings is paramount. Among the most trusted choices is 5083 marine aluminum.

View Details5083 Marine Aluminum Customized Shapes for Coastal Infrastructure Design and Build

When it comes to the demanding environments of coastal infrastructure design and build, 5083 Marine Aluminum continues to solidify its leadership with exceptional strength and corrosion resistance.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability.

View DetailsMarine Aluminum Fencing and Railings for Durable Boat Deck Guardrails

OverviewMarine aluminum fencing and railings are purpose-designed alloy systems used for guardrails, handrails, stanchions, and safety barriers on boats, docks, marinas, and waterfront properties.

View Details5083 Marine Aluminum Customized Shapes for Saltwater Resistant Boat Deck Frames

When it comes to boat deck frames that endure the relentless challenge of saltwater environments, the choice of materials is paramount. Among all options.

View Details

Leave a Message