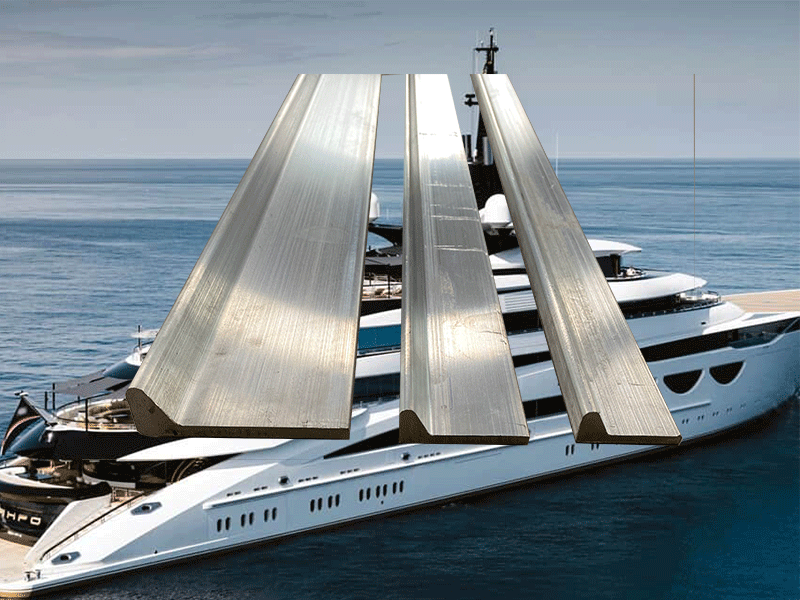

Marine Grade Aluminum Fencing and Railings are high-quality, corrosion-resistant structural components crafted to withstand harsh marine environments such as coastal regions, docks, marinas, offshore platforms, and ships. Designed from premium marine-grade aluminum alloys, these fencing and railing solutions combine durability, strength, lightweight properties, and aesthetic appeal to provide safe, long-lasting, and maintenance-friendly barriers and guardrails in saltwater-exposed applications.

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions. The inherent corrosion resistance of these alloys ensures that fencing and railing structures maintain their integrity and aesthetic appeal over extended service lives despite exposure to aggressive salt spray and fluctuating weather.

These systems commonly include posts, handrails, pickets, panels, and gates, which are fabricated into customizable designs meeting various safety standards and architectural preferences. The lightweight nature of aluminum allows for easier handling and installation compared to heavier metals like steel, without sacrificing safety or performance.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Marine-Grade Aluminum Alloys | Typically 5083, 5052, or 6061 alloys selected for saltwater corrosion resistance | Extended durability in coastal and marine environments |

| Lightweight Construction | Density approximately 2.66 g/cm³, far lighter than steel | Easier installation and reduced structural load |

| High Strength and Rigidity | Provides reliable load-bearing and impact resistance for safety barriers | Ensures structural stability and code compliance |

| Low Maintenance | Aluminum naturally forms a protective oxide layer resisting rust and degradation | Reduced maintenance cost and longer lifecycle |

| Customizable Designs | Wide variety of profiles, finishes, and styles tailored to project aesthetics | Blends safety with architectural appeal |

| Excellent Fabricability | Easily cut, welded, anodized, powder-coated, or painted | Flexibility in fabrication and finishes |

| Non-Magnetic & Environmentally Friendly | Safe for sensitive marine electronics and fully recyclable | Suitable for eco-conscious projects and advanced vessels |

Typical Marine Aluminum Alloys for Fencing and Railings

| Alloy | Key Attributes | Common Use Cases |

|---|---|---|

| 5083 | High magnesium content, outstanding corrosion resistance | Heavy-duty structural components |

| 5052 | Good formability and corrosion resistance | Decorative railings and fencing |

| 6061 | Heat-treatable for superior strength and finish | Load-bearing parts and supports |

Manufacturing and Finishing

Fabrication: Marine aluminum fencing and railings are often fabricated by extrusion, bending, cutting, welding, and assembly according to rigorous marine standards.

Surface Finishing: To further enhance resistance and aesthetics, aluminum components can be anodized, powder coated, or painted with marine-grade coatings.

Customization: Custom profiles and finishes are available to meet specific design and regulatory requirements.

Modular Systems: Many products come as modular kits for ease of installation and replacement onboard marine vessels or coastal structures.

Mechanical Properties (Typical Ranges)

| Property | 5083-H321 | 5052-H32 | 6061-T6 |

|---|---|---|---|

| Tensile Strength (MPa) | 300 – 350 | 228 – 271 | 310 – 350 |

| Yield Strength (MPa) | 145 – 215 | 103 – 138 | 270 – 300 |

| Elongation (%) | 10 – 18 | 10 – 15 | 8 – 12 |

| Hardness (Brinell) | 75 – 95 | 60 – 75 | 95 – 115 |

| Density (g/cm³) | 2.66 | 2.68 | 2.70 |

Common Applications

Ship Deck Railings: Safety rails and guardrails on passenger and commercial vessels.

Marina and Dock Fencing: Barrier fencing for piers, docks, and waterfront facilities.

Offshore Platform Guardrails: Protective barriers for workers on oil rigs and wind farms.

Coastal Walkways and Bridges: Durable railing systems resistant to salty air corrosion.

Harbor Security Fencing: Robust aluminum fencing solutions for port and harbor safety.

Custom Marine Fences and Gates: Tailored designs for marine architecture and heritage vessels.

Advantages Over Other Materials

| Criterion | Marine Aluminum Fencing & Railings | Steel Fencing & Railings | Stainless Steel Fencing & Railings |

|---|---|---|---|

| Corrosion Resistance | Exceptional; saltwater resistant without coatings | Prone to rust unless coated | Excellent but heavier and more costly |

| Weight | Lightweight for ease of handling | Heavy, challenging installation | Heavy but corrosion resistant |

| Maintenance | Low; minimal upkeep required | Regular painting and rust treatment | Moderate maintenance |

| Fabrication | Easy to cut, weld, and coat | Requires heavy-duty fabrication | Difficult and expensive fabrication |

| Cost | Moderate initial investment | Low initial cost but higher upkeep | High upfront cost |

Maintenance Tips

Routine Freshwater Cleaning: Essential to remove salt and prevent buildup.

Gentle Cleaning Materials: Use mild detergents and non-abrasive cloths or brushes.

Periodic Inspection: Check for damage, corrosion hotspots, and weld integrity.

Protective Coatings: Reapply anodizing or marine-grade paint on high-exposure or damaged areas.

Prevent Galvanic Corrosion: Use insulating materials when aluminum contacts other metals.

Marine Grade Aluminum Fencing and Railings provide an ideal combination of lightweight construction, corrosion resistance, and structural strength for demanding marine environments. Their adaptability in design and finish, combined with low maintenance requirements, make them a superior choice over traditional metals for marine, offshore, and coastal safety and security applications.

For tailored product selection, custom design support, or volume orders, contact our experienced marine aluminum team for expert advice to meet your project's unique requirements.