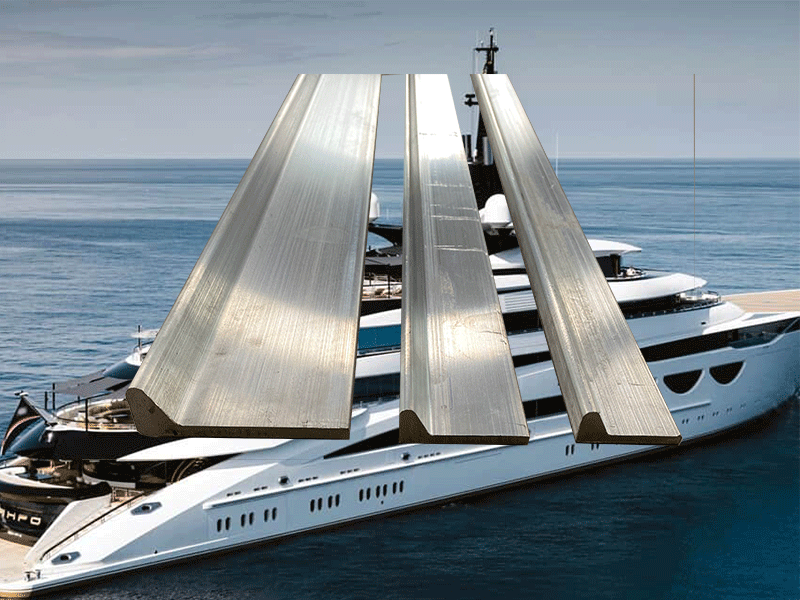

Marine Grade Aluminum Heat Sink Profiles are high-performance thermal management components specially designed for maritime and offshore applications. Manufactured from premium marine-grade aluminum alloys, these heat sink profiles combine excellent corrosion resistance with superior thermal conductivity and mechanical strength. They play a critical role in cooling electronic equipment, power systems, and lighting fixtures aboard ships, offshore platforms, and coastal infrastructures—ensuring optimal performance and longevity in harsh marine environments.

Heat sink profiles are extruded aluminum shapes designed to dissipate heat efficiently from electronic devices and other heat-generating equipment. Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

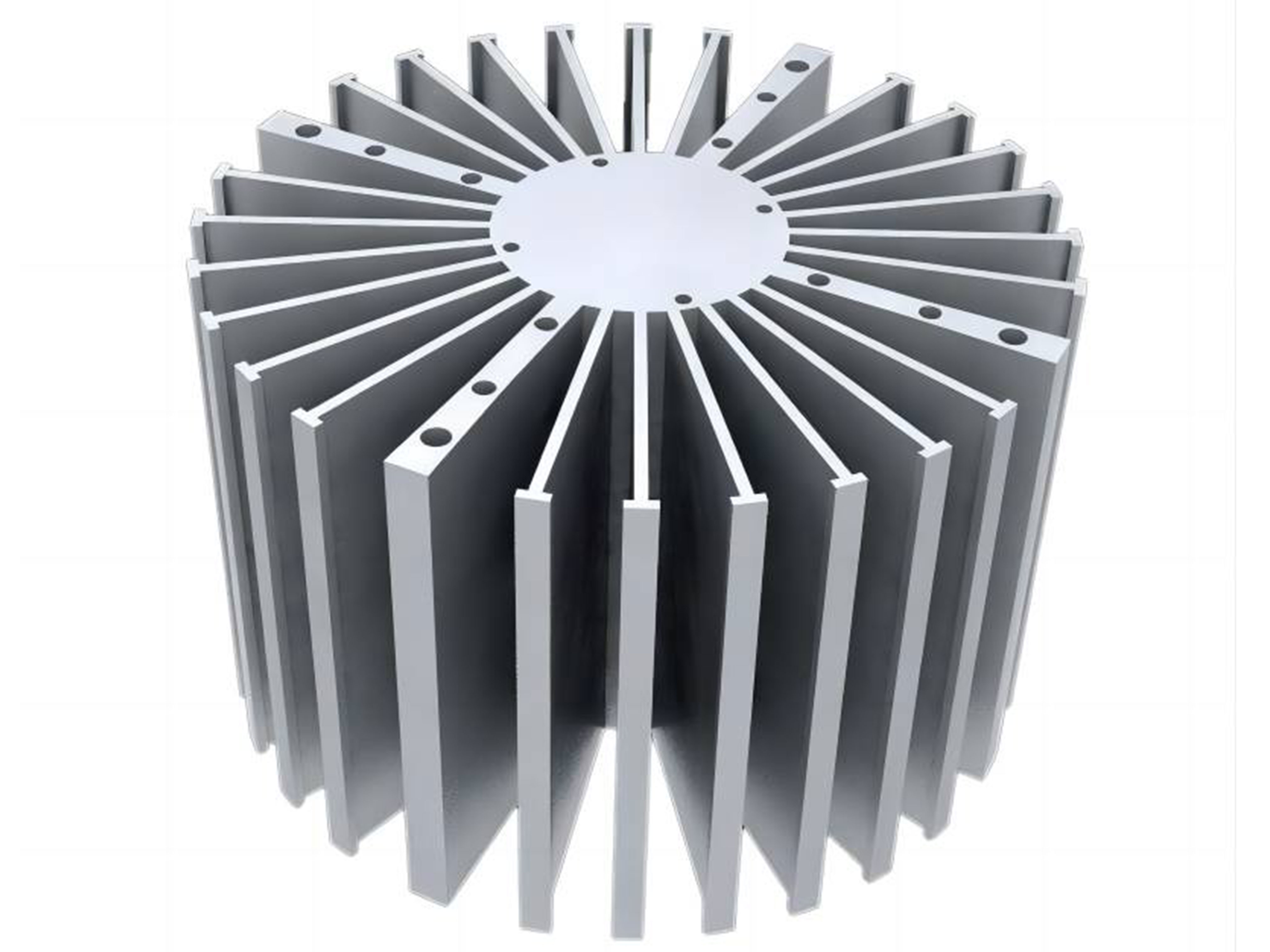

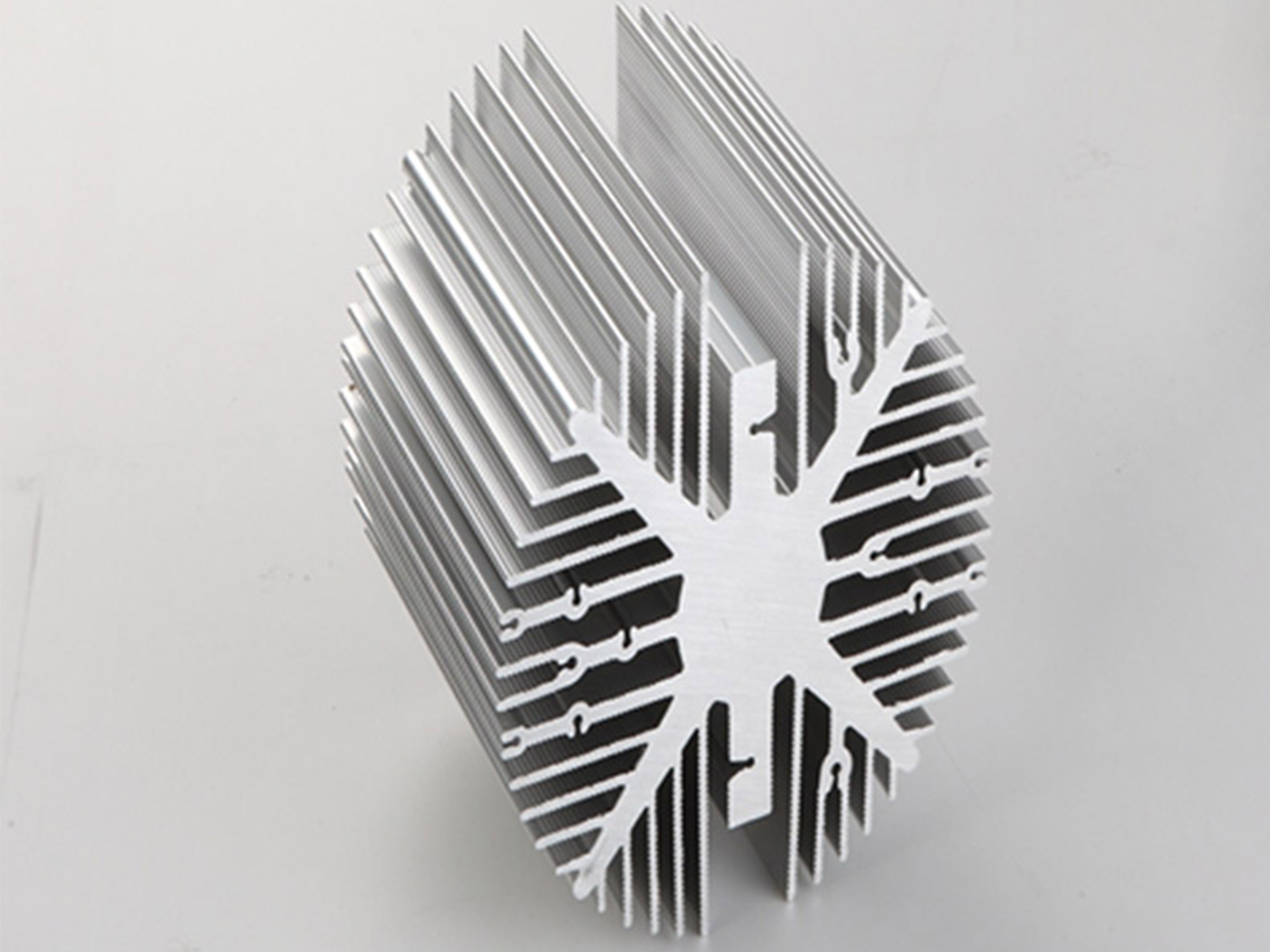

The profiles feature fins, slots, or ribbed designs maximizing surface area to enhance airflow and thermal transfer. Their lightweight nature and resistance to corrosion offer marine engineers a reliable solution for heat dissipation challenges while meeting stringent maritime durability standards.

Manufactured through precision extrusion processes, these profiles are available in customizable geometries and dimensions tailored to specific marine thermal management needs.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Marine-Grade Aluminum Alloys | Typically 6061-T6 or 6063 alloys known for high thermal conductivity and corrosion resistance | Optimal heat dissipation in salty marine atmospheres |

| Customizable Profile Geometry | Finned, ribbed, and slotted designs created to maximize surface area and airflow | Enhanced cooling efficiency tailored to application requirements |

| High Thermal Conductivity | Aluminum’s natural ability to conduct heat ensures effective temperature control | Prevents overheating, extends electronic equipment lifespan |

| Corrosion Resistance | Resistant to seawater corrosion and salt spray | Low maintenance and long service life in marine environments |

| Mechanical Strength | Strong enough to withstand mechanical stresses encountered offshore | Durable structural integrity during installation and operation |

| Lightweight and Easy to Install | Facilitates easier handling and reduces load on marine structures | Improved installation efficiency and vessel weight management |

Common Marine Aluminum Alloys for Heat Sink Profiles

| Alloy | Properties | Typical Use Cases |

|---|---|---|

| 6061 | Heat-treatable, good corrosion resistance, excellent machinability | Power electronics, control units |

| 6063 | High extrudability, smooth surface finish, corrosion resistant | Lighting fixtures, enclosures, displays |

Chemical Composition (Representative)

| Element | 6061 (%) | 6063 (%) |

|---|---|---|

| Silicon (Si) | 0.4 – 0.8 | 0.2 – 0.6 |

| Magnesium (Mg) | 0.8 – 1.2 | 0.45 – 0.9 |

| Copper (Cu) | 0.15 – 0.4 | ≤ 0.10 |

| Iron (Fe) | ≤ 0.7 | ≤ 0.35 |

| Chromium (Cr) | 0.04 – 0.35 | 0.05 – 0.35 |

| Manganese (Mn) | ≤ 0.15 | ≤ 0.10 |

| Zinc (Zn) | ≤ 0.25 | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.15 | ≤ 0.10 |

| Aluminum (Al) | Balance | Balance |

Mechanical and Thermal Properties

| Property | 6061-T6 | 6063-T5 |

|---|---|---|

| Tensile Strength (MPa) | 310 – 350 | 190 – 240 |

| Yield Strength (MPa) | 270 – 300 | 130 – 170 |

| Elongation (%) | 8 – 12 | 8 – 12 |

| Thermal Conductivity (W/m·K) | ~167 | ~201 |

| Density (g/cm³) | 2.70 | 2.70 |

Manufacturing Process

Precision Extrusion: Heat sink profiles are created by extruding heated aluminum billets through specially designed dies that produce fins, grooves, and complex shapes optimized for marine heat dissipation.

Heat Treatment: Alloys are solution treated and artificially aged to reach the required temper with maximum mechanical and thermal performance.

Surface Finishing: Profiles can be supplied in mill finish or anodized for additional corrosion protection and extended life in saline environments.

Cutting and Fabrication: Profiles are custom cut to length, with options for machining, drilling, or assembly as needed.

Typical Marine Applications

Heat sinks and cooling fins for marine electronic control systems and power converters

Thermal management components in LED lighting and display systems aboard ships

Enclosures and housings for navigation, communication, and instrumentation equipment

Cooling systems for onboard machinery, radar, and sensors

Offshore oil and gas platform electronics and control panels

Renewable marine energy devices such as wind turbines and wave energy converters

Advantages Over Alternative Materials

| Aspect | Marine Aluminum Heat Sink Profiles | Copper Heat Sinks | Steel Heat Sinks |

|---|---|---|---|

| Corrosion Resistance | Excellent in seawater and salt spray | Poor without coating | Very poor without significant maintenance |

| Weight | Lightweight (2.7 g/cm³) | Heavy (~8.9 g/cm³) | Very heavy (~7.85 g/cm³) |

| Thermal Conductivity | High (~160-200 W/m·K) | Very high (~400 W/m·K) | Low (~50 W/m·K) |

| Fabrication and Machinability | Excellent | Difficult to machine | Moderate |

| Cost | Cost-effective | Expensive | Inexpensive but high maintenance |

Maintenance and Care Recommendations

Rinse regularly with fresh water to remove salt and marine residues.

Clean anodized or coated surfaces with mild detergent and soft cloths to maintain corrosion protection.

Inspect for mechanical damage or corrosion, especially near mounting surfaces or welds.

Avoid harsh abrasives or chemicals that can compromise surface finishes.

Touch up damaged coatings or anodizing to sustain protection in harsh environments.

Marine Grade Aluminum Heat Sink Profiles offer marine and offshore industries a durable, corrosion-resistant, and efficient thermal management solution tailored for demanding saltwater environments. Their combination of lightweight construction, high thermal conductivity, and excellent fabrication adaptability make them a vital component for protecting delicate electronic and power equipment aboard vessels and offshore platforms.

For customized design, expert consultation, or volume orders of marine-grade aluminum heat sink profiles, please contact our dedicated sales and engineering team who will assist in delivering the ideal solution for your marine thermal management needs.