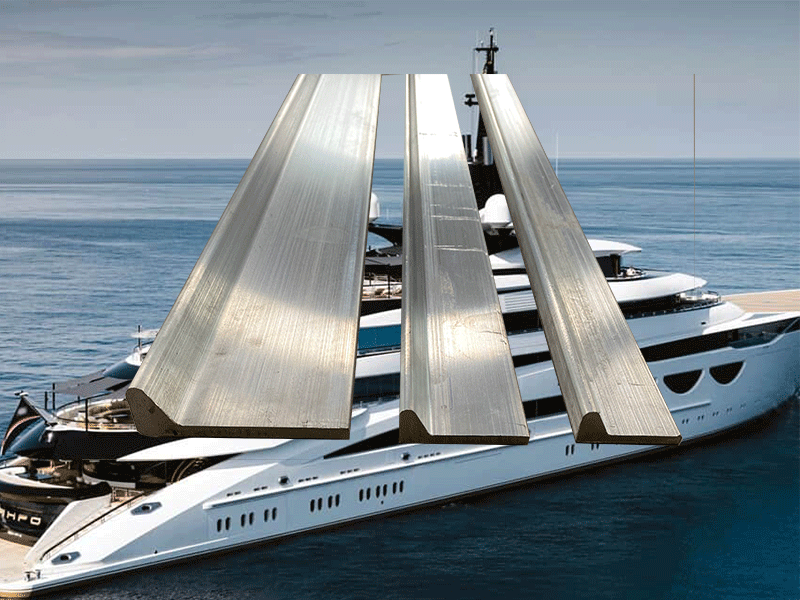

Marine Grade Aluminum Customized Shapes are precision-engineered aluminum components fabricated to meet the unique and demanding requirements of marine and offshore industries. Designed from premium marine-grade aluminum alloys, these customized profiles enable engineers, architects, and fabricators to develop innovative solutions tailored specifically to project needs in challenging saltwater and coastal environments. Offering exceptional corrosion resistance, strength, and versatility, Marine Grade Aluminum Customized Shapes play a pivotal role in enhancing the reliability and longevity of marine structures and equipment.

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries. These customized shapes are made from marine alloys like 5083, 5052, 6061, and 6082, selected to provide optimal seawater corrosion resistance, mechanical performance, and fabrication ease.

Through high-precision extrusion or fabrication techniques, these shapes can include intricate ribs, slots, flanges, hollow sections, or other features that enhance structural support, assembly integration, and marine functionality. Their lightweight nature substantially reduces structural weight and installation complexity on vessels and offshore infrastructure.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Premium Marine Aluminum Alloys | Superior corrosion resistance from alloys such as 5083, 5052, 6061, and 6082 | Long-lasting durability in saltwater and marine atmospheres |

| Tailored Profile Design | Custom cross-sections designed per project requirements | Maximizes performance while reducing material waste and weight |

| High Precision Fabrication | Advanced extrusion, rolling, and machining techniques | Ensures tight dimensional tolerances and superior surface quality |

| Lightweight Structural Solutions | Density around 2.66–2.70 g/cm³ significantly reduces vessel weight | Improves fuel efficiency and payload capacity |

| Excellent Mechanical Properties | High tensile and yield strength balanced with ductility | Supports demanding structural and mechanical marine applications |

| Fabrication Versatility | Compatible with cutting, welding, bending, and assembly | Facilitates streamlined manufacturing and on-site modifications |

| Environmental Sustainability | Fully recyclable alloys and environmentally friendly processes | Reduces project environmental footprint |

Common Marine Aluminum Alloys for Customized Shapes

| Alloy | Typical Composition & Properties | Typical Applications |

|---|---|---|

| 5083 | High Mg (~4-4.9%), excellent pitting resistance, strong welding properties | Hull reinforcements, offshore structures |

| 5052 | Moderate Mg (~2.2-2.8%), excellent formability and corrosion resistance | Panels, trim, and fabrications with curved profiles |

| 6061 | Mg-Si alloy, heat-treatable, high strength and corrosion resistance | Structural beams, machined parts, frames |

| 6082 | Higher strength 6xxx with good corrosion and fatigue resistance | Heavy-duty structural profiles and connectors |

Manufacturing Processes

Custom Extrusion: Hot aluminum billets are extruded through dedicated dies to produce project-specific shapes with complex cross-sections, integrated features, and consistent quality.

Rolling and Forming: For certain shapes, rolling or bending techniques refine or develop profiles within precise tolerances.

Machining and Finishing: CNC machining, drilling, welding, and surface treatments such as anodizing or powder coating enhance function and appearance.

Quality Control: Rigorous dimensional inspections and mechanical testing ensure compliance with marine standards and customer specifications.

Typical Marine Applications

Custom structural supports and framing systems in shipbuilding and offshore platforms.

Specialized marine equipment housings and enclosures with integrated ventilation or access features.

Lightweight superstructure components and architectural elements in coastal constructions.

Complex flange, ribbed, and channel sections for deck reinforcements and bulkheads.

Hull stiffeners, stringers, and brackets uniquely designed for vessel hull geometries.

Custom fabricated rails, ladders, and safety barriers optimized for marine use.

Advantages Over Standard Aluminum Profiles

| Aspect | Customized Marine Aluminum Shapes | Standard Aluminum Profiles |

|---|---|---|

| Design Flexibility | Fully tailored cross-sections and features | Limited to traditional shapes |

| Performance | Optimized for strength, weight, and function | General-purpose, less optimized |

| Integration | Designed for easy assembly and compatibility | May require additional fabrication |

| Cost Efficiency | Material savings through precision design | Potential waste with off-the-shelf shapes |

| Maintenance | Designed to minimize corrosion traps | Standard shapes may have more crevices |

Maintenance Guidelines

Routine Cleaning: Regular freshwater rinsing removes salt and contaminants, preserving surface integrity.

Use Mild Detergents: Avoid harsh chemicals and abrasive tools that could damage protective coatings or anodized finishes.

Visual Inspection: Periodically examine for signs of mechanical wear, impact damage, or corrosion, especially around welds and joints.

Protective Coatings: Apply or renew anodizing or marine-grade paint coatings in high-exposure or abrasive environments.

Proper Storage: When not in use, store profiles in dry, ventilated spaces to prevent exposure to corrosive elements.

Marine Grade Aluminum Customized Shapes unlock the full potential of aluminum structural design for marine and offshore applications. By leveraging corrosion-resistant alloys and advanced fabrication techniques, these bespoke profiles enable designers and engineers to optimize structural performance, weight savings, and longevity in harsh marine environments. Whether required for complex hull reinforcements, custom equipment housings, or specialized architectural elements, customized marine aluminum shapes offer tailored, reliable, and sustainable solutions.

For technical consultation, prototype development, or bulk manufacturing inquiries, contact our marine metals experts who are dedicated to delivering customized aluminum solutions precisely aligned with your project demands.