5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability. Among all contenders, 5083 marine aluminum customized shapes have become a material of choice for offshore vessel deck reinforcement applications.

Why 5083 Aluminum Suitable for Offshore Vessel Deck Reinforcements?

5083 aluminum is an aluminum-magnesium alloy noted for its high strength-to-weight ratio, extraordinary corrosion resistance, particularly in marine environments, and excellent weldability. These qualities enable 5083 aluminum shapes—be it plates, extrusions, or forged profiles—to augment strength on decks exposed to severe mechanical loads and saline atmosphere over extended service.

Functional Benefits:

- Superior Corrosion Resistance: The high magnesium (4.0—4.9%) and trace amounts of manganese (~0.4%) macrophosphorus provide a uniform oxide film resisting pitting, crevice and stress-corrosion cracking common in seawater.

- High Tensile Strength: Tensile strength typically upwards of 290 MPa (42,000 psi), exceeding many aluminum alloys.

- Excellent Weldability and Formability: Easily welded with consistent strength post weld thanks to patented oxide film and tempering methods.

- Lightweight Yet Durable: Allows deck weight savings without compromising vessel stability or reinforcement needs.

Technical Specification of 5083 Marine Aluminum

The general chemical composition per ASTM B209 or ISO 6361 standards has closely controlled elements for consistency:

| Element | % by Weight (Typical) |

|---|---|

| Aluminum (Al) | Remainder |

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 |

| Chromium (Cr) | 0.05 - 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

Alloy Tempering and Mechanical Properties

The most common temper for marine applications is H116, specifically formulated to guarantee high performance in marine exposure.

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Application Note |

|---|---|---|---|---|

| H116 | 305-350 | ≥ 215 | ≥ 12 | Standard marine temper with superior corrosion resistance through specialized strain-hardened state designed for culvert and offshore enabling |

Other tempers include H112 (strain hardened to produce modifications) but H116 is preferred because it is tested for enhanced resistance against exfoliation corrosion often encountered under deck harsh conditions.

Implementation Standards & Quality

For offshore marine structures, compliance with regulatory and implementation standards is crucial:

- Classification Society Approvals: Notably DNV-GL, ABS, Lloyd’s Register, and Bureau Veritas

- International Standards:

- ASTM B928 – Specification for aluminum alloy extruded bars, rods, and profiles

- ASTM B209 – Aluminum and aluminum-alloy sheet and plate

- ISO 6361 Aluminum alloy flat rolled products

- ISO 9001 & ISO 14001-certified manufacturing often assures material traceability, consistent composition, and quality heat treatment cycles.

Fabrication Considerations and Customized Production

In offshore deck reinforcements, 5083 aluminum shapes can be tailored into plates, tubes, T-sections, I-beams, curved panels, or frames with close adherence to dimensional and metallurgical requirements.

- Cutting and Machining: Utilizes CNC machining, laser cutting; requires minimal allowance due to the alloy's low thermal conductivity.

- Welding: Best performed using MIG or TIG welding with argon shielding gas. Low thermal diffusivity reduces distortion.

- Equation of Heat Treatment: H116 temper relies on strain hardening and natural aging without solution heat treatment to maintain structural alloy integrity without compromising corrosion resistance in marine environments.

The fabrication process incorporates advanced tooling to minimize porosity and impurity inclusion, meeting strict offshore reinforcement schedules without losing metallic profile accuracy or chemical homogeneity.

Applications in Offshore Vessel Deck Reinforcements

The reinforced decks of Offshore Support Vessels (OSVs), Crew Boats, and Supply Shipping must resist impact forces, constant vibrations, localized dynamic loads, and corrosive salt spray. Customized 5083 aluminum shapes enable:

- Strengthening of load foundation points for cranes and heavy equipment.

- Structural frames resistant to fatigue from cyclical loading and hull twisting.

- Deck plating able to resist abrasion from container and equipment movement.

- Corrosion barriers minimizing maintenance downtime associated with marine saltwater exposure.

In platforms subjected to simultaneous bearing and corrosive degradation, 5083 alloy maintains fracture toughness far better than stainless steel alternatives with across-the-board efficiencies in weight savings and structural performance.

5083 marine aluminum customized shapes imperatively align with the security and extended lifecycle needs of offshore vessel deck reinforcements. When designed according to strict standards (ASTM, ISO), tempered for marine optimizations (H116), and fabricated using cutting-edge material science practices, 5083 exhibits superior durability, perfect alloy constitution, and rank-leading marine grade material integrity.

Investing in this specialized aluminum alloy enables offshore vessel manufacturers and operators to realize advanced vessel dependability, lightweight safety, and critical resistance against one of the harshest operational environments on the globe — the open sea.

For further technical consultations and product customization inquiries related to marine-grade 5083 aluminum alloy solutions, contact our marine experts. Secure your vessel’s deck reinforcement with the best marine materials engineered exactly by or for your offshore project needs.

Related Products

Marine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

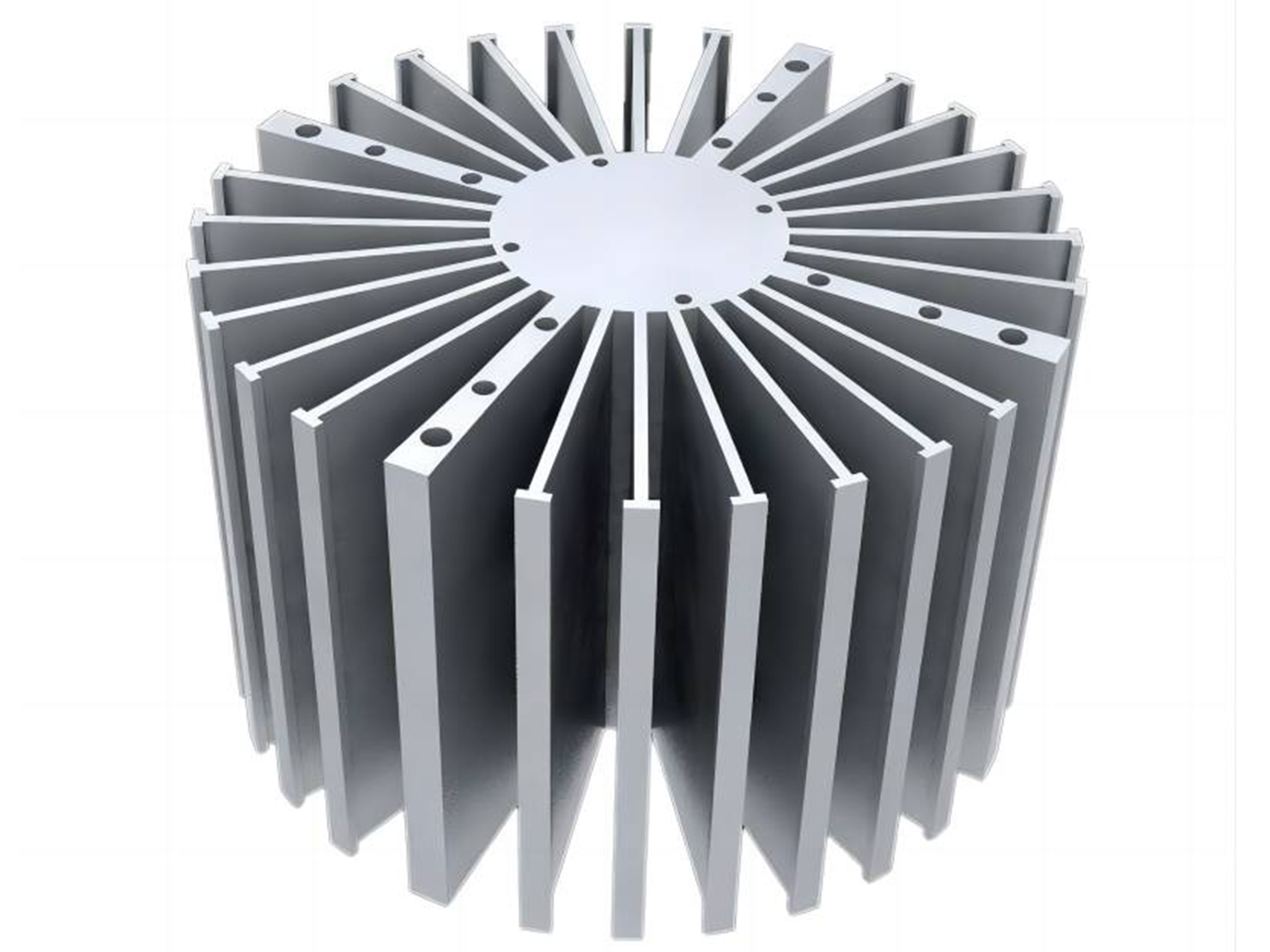

View DetailsMarine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsRelated Blog

5083 Marine Aluminum Fencing and Railings for Custom Coastal Guardrails

5083 marine aluminum is a widely used alloy for coastal guardrails, fencing, and railings because it combines excellent corrosion resistance in seawater environments, strong mechanical properties, and good weldability.

View Details5083 Marine Aluminum Customized Shapes for Coastal Infrastructure Design and Build

When it comes to the demanding environments of coastal infrastructure design and build, 5083 Marine Aluminum continues to solidify its leadership with exceptional strength and corrosion resistance.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Frame Reinforcements

When it comes to offshore vessel deck frame reinforcements, the choice of materials is critical for durability, strength, and corrosion resistance. Among the myriad of options.

View Details5083 Marine Aluminum Customized Shapes for Saltwater Resistant Boat Deck Frames

When it comes to boat deck frames that endure the relentless challenge of saltwater environments, the choice of materials is paramount. Among all options.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability.

View DetailsMarine Aluminum Fencing and Railings for Durable Boat Deck Guardrails

OverviewMarine aluminum fencing and railings are purpose-designed alloy systems used for guardrails, handrails, stanchions, and safety barriers on boats, docks, marinas, and waterfront properties.

View Details

Leave a Message