5083 Marine Aluminum Hexagonal Bars for Durable Offshore Support Parts

In the demanding world of offshore engineering and marine construction, the choice of materials is critical to ensuring long-lasting performance, safety, and cost-efficiency. Among various aluminum alloys, 5083 marine aluminum hexagonal bars have emerged as a preferred material for durable offshore support parts due to their exceptional corrosion resistance, high strength, and excellent weldability.

5083 aluminum alloy belongs to the 5xxx series, defined primarily by its magnesium (Mg) content which imparts excellent strength and resistance to seawater corrosion. When fabricated into hexagonal bars, the geometry supports complex machining and robust mechanical joining suitable for various offshore structures, including skids, supports, heat exchangers, and framework components.

Chemical Composition (% by weight)

| Element | Typical Range | Standard Limit (ASTM B221) |

|---|---|---|

| Aluminum (Al) | Balance | 94.4 - 96.8 |

| Magnesium (Mg) | 4.0 - 4.9 | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 | 0.4 - 1.0 |

| Chromium (Cr) | 0.05 - 0.25 | 0.05 - 0.25 |

| Iron (Fe) | ≤ 0.4 | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 | ≤ 0.15 |

Note: Trace elements and other impurities are controlled typically under 0.15% total.

Alloy Temper and Heat Treatment

- Temper Available: O (Annealed), H111 (Slightly Strain-Hardened), H32 (Strain-Hardened and Stabilized)

- Recommended Temper for Offshore Components: H32 and H111 temper provide an optimal balance of mechanical strength and formability.

- Annealing Specifications: 350°C (approx.) annealing for enhanced ductility and stress relaxation.

Mechanical Properties

| Property | Typical Value | Testing Standard |

|---|---|---|

| Tensile Strength (MPa) | 275 – 350 | ASTM B928 / ASTM E8 |

| Yield Strength (MPa) | 125 – 215 | ASTM B928 / ASTM E8 |

| Elongation (%) | 12 – 18 | ASTM B928 / ASTM E8 |

| Hardness (Brinell) | 75 – 90 | ASTM E10 |

| Density (g/cm³) | 2.66 | ASTM B936 |

| Modulus of Elasticity (GPa) | 70 | ASTM E111 |

Corrosion Resistance

5083 marine aluminum boasts excellent resistance to pitting and saltwater corrosion due to its magnesium content plus small amounts of chromium. This resilience enables long-term deployment in seawater and harsh saline conditions without significant degradation. It also performs well against stress corrosion cracking, a critical requirement in offshore applications.

Standards & Compliance

5083 hexagonal bars adhere to the following industrial and international standards often required in marine industries:

- ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Bars, Rods, and Wire

- ISO 6361: Rolled Aluminum and Aluminum Alloy Sheets, Strips, and Plates

- ABS & DNV GL standards: For use in marine grade aluminum, offshore platform construction, and structural components certification

- Marine and Offshore Engineering Guidelines: Material certification and traceability with mill test reports (MTR)

Manufacturing and Machinability

- The hexagonal bar shape offers a high cross-sectional area and uniform geometry aligned with advanced CNC machining, drilling, and milling for support fixtures, structural fasteners, and flanges.

- Easy to weld using TIG/MIG techniques with compatible filler metals such as ER5183 or ER5356 for stress-resistant joints.

- Surface finishing options include anodizing, mechanical polishing, or protective primers as specified for corrosion mitigation and aesthetic requirements.

Applications

- Offshore oil and gas platform frameworks, braces, and tie rods

- Marine structural components including winches, ladders, bulkheads, and fasteners

- Shipbuilding mount supports and machinery bases

- Underwater tooling supports and frameworks exposed to saline environments

Related Products

Marine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsRelated Blog

5083 Marine Grade Aluminum Solid Bar for Offshore Vessel Frame Parts

In the demanding environment of offshore vessels, structural integrity, durability, and corrosion resistance are critical factors that determine overall vessel performance and safety.

View Details5083 5052 H32 60mm aluminum bar for boat

High-performance 5083 and 5052 H32 60mm aluminum bars tailored for marine applications. Ideal for boat building with excellent corrosion resistance, superior strength, and formability.

View Details5083 Marine Grade Aluminum Solid Bar for Boat Hull Reinforcement

In the expansive world of marine construction and engineering, selecting the right materials can make the difference between a resilient vessel and costly structural failures.

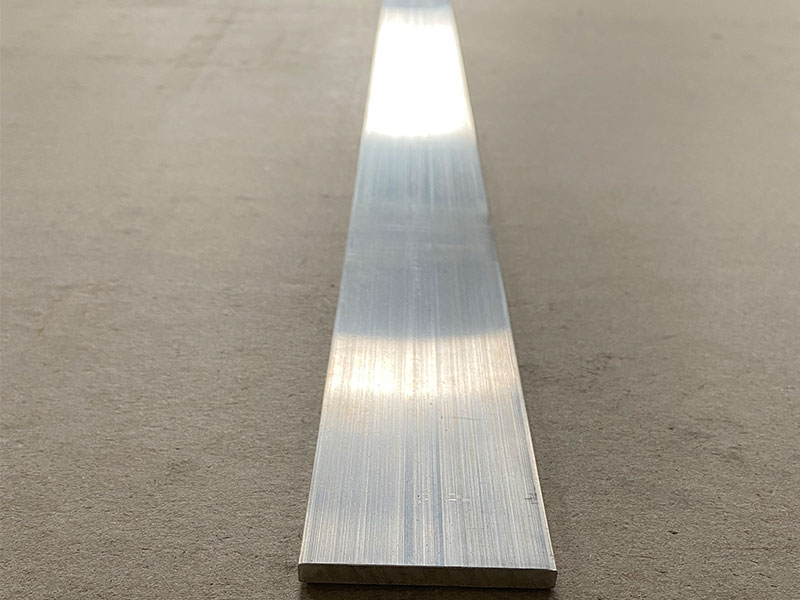

View Details5083 Marine Aluminum Hexagonal Bars for Durable Offshore Support Parts

Explore premium 5083 marine aluminum hexagonal bars tailored for offshore support applications. their superior corrosion resistance, alloy composition, mechanical properties, and industry implementation standards.

View Details5083 Marine Aluminum Bar for Marine Equipment Reinforcements

Superior strength, corrosion resistance, and reliability of 5083 Marine Aluminum Bars, specifically engineered for marine equipment reinforcements. Ideal for harsh sea environments, these aluminum bars offer exceptional mechanical properties and long-term

View Details5083 Marine Aluminum Bar for High Strength Marine Vessel Parts

5083 Marine Aluminum Bar for High Strength Marine Vessel Parts: Durability Meets PerformanceWhen it comes to constructing high-performance marine vessels, material selection is paramount.

View Details

Leave a Message