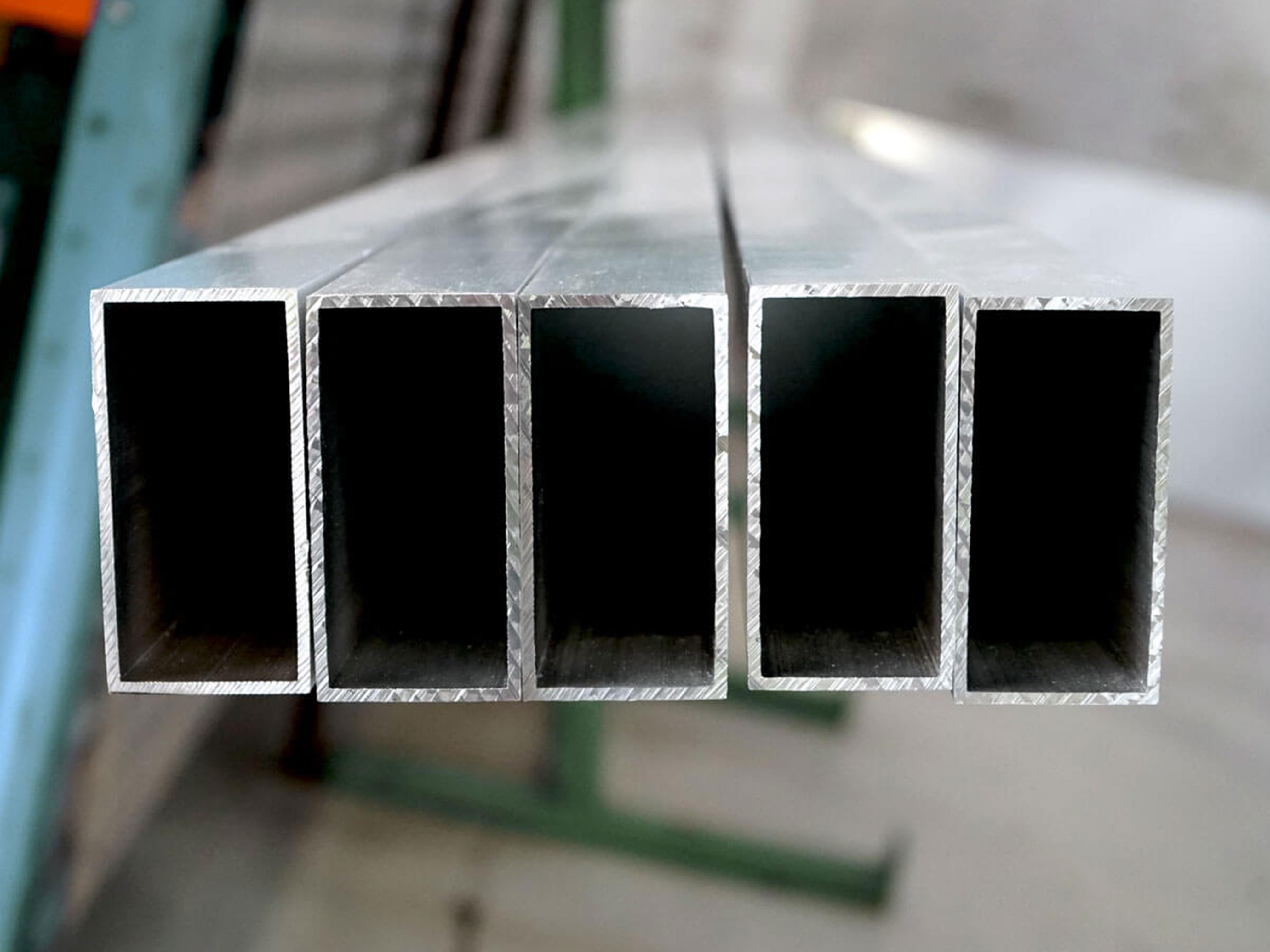

6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability. This makes them the ideal choice for demanding marine engine component support structures where reliability under harsh conditions is critical. As a highly versatile section form, these aluminum tubes combine light-weight properties with remarkable durability essential in marine environments, particularly chassis frames, mounts, supports, heat exchangers, and hydraulic piping related to marine engine systems.

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Bal. |

| Magnesium (Mg) | 0.6 - 1.2 |

| Silicon (Si) | 0.7 - 1.3 |

| Manganese (Mn) | 0.4 - 1.0 |

| Iron (Fe) | ≤ 0.5 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.2 |

| Others | ≤ 0.15 |

Mechanical Properties

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 290 - 340 MPa | ASTM B211 |

| Yield Strength | 260 - 300 MPa | ASTM B211 |

| Elongation | ≥ 8% | ASTM E8 |

| Hardness (Brinell) | 95 - 110 HB | ASTM E10 |

| Density | 2.70 g/cm³ | — |

| Modulus of Elasticity | 70 GPa | ASTM E111 |

Features

Superior Corrosion Resistance for Marine EnvironmentsThanks to its alloying elements & proprietary grain refinement, 6082 aluminum—the member of the 6xxx series—offers outstanding resistance against seawater corrosion and salt spray compared to many other aluminum alloys. This minimizes corrosion-related failures for marine engine components over extended service life.

Excellent Mechanical StrengthWith high tensile and yield strength values, 6082 provides structural soundness in demanding applications. Its strength-to-weight ratio ensures support components withstand engine vibrations and mechanical loading without undue deformation or fatigue.

Weldability and Fabrication FriendlyDesigned to be easy to form and weld, 6082 tubes simplify complex installation requirements under space-constrained marine engine rooms or hull frameworks. Mechanical fastening or TIG welding generally yield reliable joint integrity for frames, brackets, and pipe supports.

Thermal and Fatigue ResistanceThe alloy performs well under repeated thermal cycling, making it suited to engines undergoing temperature variation. It is less prone to crack initiation and growth thereby improving overall maintenance cycle intervals.

Lightweight ConstructionThe low density of aluminum reduces the structure weight, promoting fuel savings and improving buoyancy of vessels when used in load-bearing supports.

Typical Dimensions and Form Factors

| Wall Thickness (mm) | Outer Diameter (mm) | Length (m) | Custom Options: OD & Wall Thickness |

|---|---|---|---|

| 2.0 - 12.0 | 20 - 150 | 6 | Available on request |

Standard tubing is provided in seamless or welded forms, both optimizable for tensile strength and surface finish per customer requirement.

Applications in Marine Engine Component Support

- Engine Mounting Systems: The 6082 tube’s robustness supports soft mounts and chocks that absorb vibrations and stiff loads.

- Heat Exchanger Frames: Structurally stable frames to hold CO2, freshwater cooling tubes despite high thermal stresses and corrosive seawater exposure.

- Hydraulic Piping Supports: Lubrication or ballast hydraulics piping lineup reinforced using 6082 provides long-term resistance to abrasion and fatigue.

- Structural Reinforcements & Beams: Lightweight but rigid tubular reinforcements minimizing added boat weight while maintaining engine room stiffness.

- Fuel Delivery Framework: Secure mounting of fuel line trims impacting safety and operational efficiency.

Quality Assurance

Each batch of 6082 marine aluminum tubes undergoes strict chemical analysis, mechanical testing including destructive and non-destructive tests, and surface inspection protocols. Certifications on request per shipbuilding and marine class standards such as DNV GL or ABS can also be arranged.

Related Products

Marine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

6082 Marine Aluminum Tubes for Saltwater Exposure Resistant Boats

Advantages of 6082 marine aluminum tubes, specifically engineered for saltwater exposure resistant boats. Learn about their chemical composition, mechanical properties, tempering conditions, implementation standards, and why they are the optimal choice in

View Details6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

View Details6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability.

View Details6082 Marine Aluminum Round Tubes for Offshore Construction

In the demanding arena of offshore construction, selecting materials that combine strength, corrosion resistance, and manufacturability is crucial for ensuring durability and safety.

View Details

Leave a Message