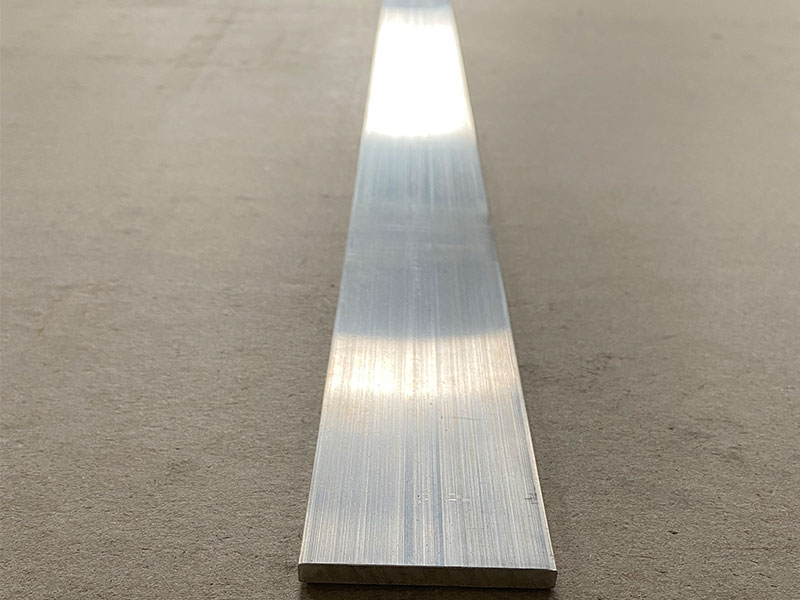

5083 Marine Grade Aluminum Solid Bar for Boat Hull Reinforcement

In the expansive world of marine construction and engineering, selecting the right materials can make the difference between a resilient vessel and costly structural failures. Among the myriad options available, 5083 marine grade aluminum solid bars have emerged as a crucial component, offering unparalleled strength and durability for boat hull reinforcement.

5083 Marine Grade Aluminum: At the Core

5083 aluminum is an alloy predominantly composed of aluminum, magnesium (4.0-4.9%), and trace amounts of manganese, chromium, and other elements. The inclusion of magnesium significantly enhances its corrosion resistance, especially against the harsh saline environments typical to marine settings. This corrosion resistance is not merely surface-level—it penetrates deep ways, preventing rust and deleterious effects that weaken other metals.

The “marine grade” descriptor indicates that the alloy meets stringent ASTM and ISO criteria for marine applications, ensuring that it can withstand continuous exposure to seawater, marine pollutants, and mechanical stresses over long periods without major degradation.

The Solid Bar Form: Why It Matters for Hull Reinforcement

While 5083 aluminum sheets and plates are widely recognized for constructing hull exteriors, the solid bar form offers specific advantages that are pivotal in reinforcement roles. Unlike hollow or hollow-formed structures, solid bars provide compressive and tensile strength uniformly across their cross-section, making them ideal for internal supports and attachment points that experience multi-directional stress.

The use of 5083 solid bars in boat hull reinforcement is particularly strategic because:

Structural Integrity: Solid bars introduce localized reinforcements without adding significant weight, maintaining the hull’s integrity while preserving maneuverability and fuel efficiency.

Weldability: The homogeneous internal structure and high magnesium content improve weldability, enabling secure connections with other hull layers or components.

Fatigue Resistance: Marine vessels encounter variable and repeated loading due to waves, accelerations, and impacts. 5083 solid bars exhibit high fatigue resistance, ensuring long-lasting reinforcement.

Dimensional Stability: Exposure to temperature changes can cause expansion and contraction; this alloy maintains dimensional stability, reducing risks of cracks.

Functional Roles in Boat Hull Reinforcement

Keel Reinforcement: The keel bears substantial loads, both from water pressure and mechanical stresses when the boat grounds or contacts docking structures. Embedding 5083 solid bars along the keel offers enhanced impact resistance, protecting the foundation of the hull.

Frame Support: Internal frames often require supplementary support where hull plates meet, or where engine mounts and heavy machinery exert force. The strength and rigidity of 5083 bars boost frame durability, mitigating flex and distortion.

Corrosion-Resistant Fastening Points: Machinery attachments, stringers, and deck fittings anticipated to experience both mechanical stress and marine corrosion perform optimally when anchored to 5083 solid aluminum bars ensuring the fastening points remain secure over time.

Hull Transitions and Reinforced Corners: The junctions of curved hull plates and bulkheads, are natural stress concentrators. Installing marine grade aluminum solid bars here distributes stress efficiently, increasing hull toughness.

From a metallurgical vantage point, what sets 5083 apart is the interplay between its microstructure and marine environment performance:

Magnesium-Driven Corrosion Resistance: Unlike other alloys that rely predominantly on zinc for strength, magnesium in 5083 encourages the formation of a passive oxide film on the surface. This film acts as a natural shield against chloride ions in seawater which are responsible for pitting corrosion.

Non-Heat Treatable Strength: 5083 gains strength primarily through strain hardening due to cold working (designated as H116 or H321 temper) as opposed to heat treatments. This gives engineers flexibility to shape solid bars into size while retaining strength, critical for custom reinforcements.

High Manganese Content: Although seemingly minor, manganese helps reduce harmful grain boundary precipitates which could otherwise degrade ductility and toughness, particularly under cyclic loads from waves.

these nuances influences how marine engineers manipulate the bars for optimal hull reinforcement. For example, temper designations are carefully chosen during fabrication to balance flexibility with hardness, tailoring reinforcement to give maximum performance in stress hotspots.

Application in Modern Marine Engineering: Case Studies

Small to Medium-sized Fishing Boats: Typically constructed with welded aluminum hulls; using 5083 solid bars internally reinforces the framework allowing these vessels to endure rough sea conditions and impacts from fishing gear and accidental collisions without compromising speed or efficiency.

Luxury Yachts and Passenger Ferries: For vessels combining robust durability with aesthetic appeal, interior corrosive resistance and structural reliability of 5083 make it ideal in forming stair supports, interior bulkheads, and fastening points invisible to customers but critical to safety.

Military and Work Boats: Rigorous duty cycles demand reinforcements that can sustain constant mechanical stresses while bearing weapons or heavy cargo—roles admirably fulfilled by custom-shaped 5083 bars.

Related Products

6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsRelated Blog

5083 Marine Aluminum Bar for Saltwater Corrosion Resistant Boat Frames

In the demanding marine environment, selecting the right materials for boat frames is vital to ensuring longevity, performance, and safety. Among the myriad of alloys.

View Details5083 Marine Aluminum Bar for Marine Equipment Reinforcements

Superior strength, corrosion resistance, and reliability of 5083 Marine Aluminum Bars, specifically engineered for marine equipment reinforcements. Ideal for harsh sea environments, these aluminum bars offer exceptional mechanical properties and long-term

View Details5083 Marine Aluminum Hexagonal Bars for High Strength Shipbuilding Materials

When it comes to constructing robust, lightweight, and corrosion-resistant components in the marine industry, 5083 marine aluminum hexagonal bars are an indispensable material.

View Details5083 Marine Aluminum Hexagonal Bars for Durable Offshore Support Parts

Explore premium 5083 marine aluminum hexagonal bars tailored for offshore support applications. their superior corrosion resistance, alloy composition, mechanical properties, and industry implementation standards.

View Details5083 Marine Grade Aluminum Solid Bar for Boat Hull Reinforcement

In the expansive world of marine construction and engineering, selecting the right materials can make the difference between a resilient vessel and costly structural failures.

View Details5083 Marine Aluminum Bar for High Strength Marine Vessel Parts

5083 Marine Aluminum Bar for High Strength Marine Vessel Parts: Durability Meets PerformanceWhen it comes to constructing high-performance marine vessels, material selection is paramount.

View Details

Leave a Message