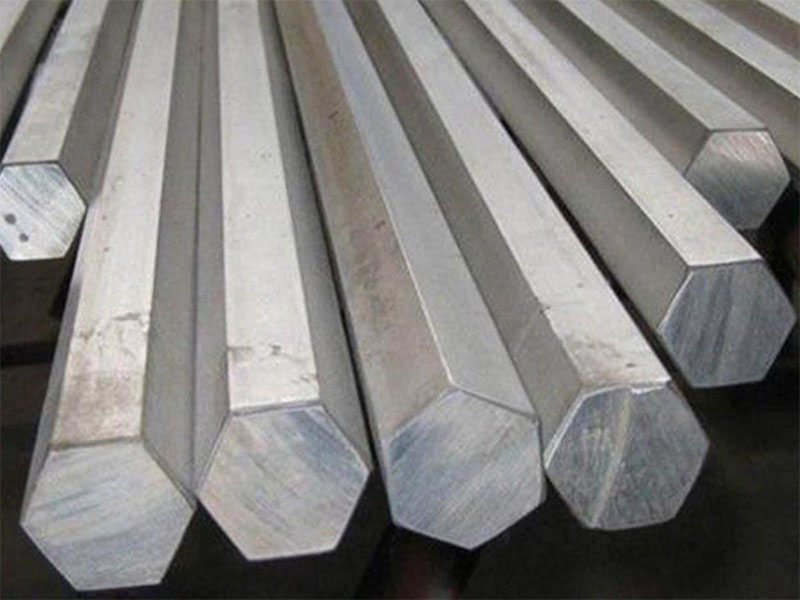

Marine Grade Aluminum Hexagonal Bars are specialized aluminum alloy bars manufactured to meet the demanding requirements of marine and offshore environments. These hexagonal cross-section bars offer exceptional corrosion resistance, high strength-to-weight ratio, and excellent machinability, making them well-suited for structural, mechanical, and fabrication applications in ships, offshore platforms, and coastal infrastructure.

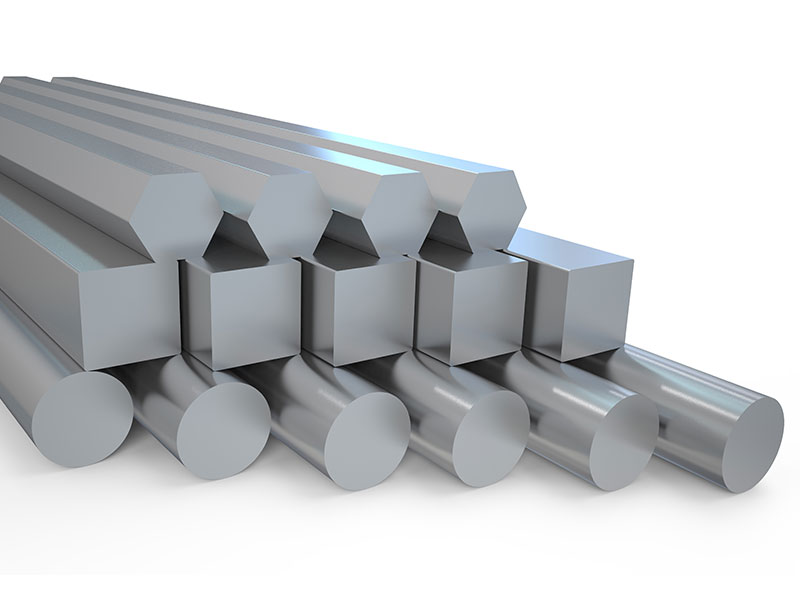

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082. The distinctive hexagonal shape provides ease of handling, enhanced grip, and specific design benefits for mechanical assembly and structural use.

These bars combine the inherent advantages of marine-grade aluminum—including resistance to saltwater corrosion and UV degradation—with geometric versatility that allows for precise applications in marine engineering. The alloy composition ensures durability and minimal maintenance in aggressive marine conditions, while maintaining sufficient strength and workability for complex marine fabrication.

Common Marine-Grade Aluminum Alloys for Hexagonal Bars

| Alloy | Composition Highlights | Typical Marine Applications |

|---|---|---|

| 5083 | High Mg content (4.0-4.9%), excellent corrosion resistance, good strength | Structural reinforcements, ship components |

| 5052 | Moderate Mg (~2.5%), excellent formability, good corrosion resistance | Equipment fittings, brackets, parts requiring bending |

| 6061 | Heat-treatable, good strength and weldability, corrosion resistant when anodized | Load-bearing parts, machined marine hardware |

| 6082 | High strength 6xxx alloy with enhanced corrosion resistance | Shafts, pins, and elements requiring high strength |

Chemical Composition (Representative)

| Element | 5083 (%) | 5052 (%) | 6061 (%) | 6082 (%) |

|---|---|---|---|---|

| Magnesium (Mg) | 4.0 – 4.9 | 2.2 – 2.8 | 0.8 – 1.2 | 0.6 – 1.2 |

| Silicon (Si) | ≤ 0.4 | ≤ 0.25 | 0.4 – 0.8 | 0.7 – 1.3 |

| Chromium (Cr) | 0.05 – 0.25 | 0.15 – 0.35 | 0.04 – 0.35 | 0.25 – 0.45 |

| Copper (Cu) | ≤ 0.1 | ≤ 0.1 | 0.15 – 0.4 | ≤ 0.1 |

| Iron (Fe) | ≤ 0.4 | ≤ 0.4 | ≤ 0.7 | ≤ 0.5 |

| Manganese (Mn) | 0.4 – 1.0 | ≤ 0.1 | ≤ 0.15 | 0.4 – 1.0 |

| Zinc (Zn) | ≤ 0.25 | ≤ 0.1 | ≤ 0.25 | ≤ 0.2 |

| Titanium (Ti) | ≤ 0.15 | ≤ 0.03 | ≤ 0.15 | ≤ 0.1 |

| Aluminum (Al) | Balance | Balance | Balance | Balance |

Mechanical Properties (Typical Values in T6 or H321 Temper)

| Property | 5083-H321 | 5052-H32 | 6061-T6 | 6082-T6 |

|---|---|---|---|---|

| Tensile Strength (MPa) | 300 – 350 | 228 – 271 | 310 – 350 | 280 – 340 |

| Yield Strength (MPa) | 145 – 215 | 103 – 138 | 270 – 300 | 240 – 300 |

| Elongation (%) | 10 – 18 | 10 – 15 | 8 – 12 | 8 – 12 |

| Hardness (Brinell) | 75 – 95 | 60 – 75 | 95 – 115 | 95 – 135 |

| Density (g/cm³) | 2.66 | 2.68 | 2.70 | 2.70 |

Manufacturing Process

Extrusion: Aluminum billets are heated and extruded through precise dies to create uniform hexagonal bars with consistent dimensions and smooth surfaces.

Heat Treatment: Depending on alloy and temper, solution heat treatment and artificial aging are applied to achieve desired strength and toughness.

Surface Treatment: Supplied in mill finish although anodizing or painting options can enhance corrosion resistance and appearance.

Cutting & Fabrication: Cut to length and machined as necessary for marine fabrication and assembly.

Typical Marine Applications

Structural fasteners, connectors, and pins requiring corrosion resistance and high strength.

Marine shaft components and mechanical linkages.

Brackets, supports, and frame members in shipbuilding and offshore platform construction.

Custom machinery parts and equipment housings exposed to marine conditions.

Lightweight, corrosion-resistant tools and handling equipment for maritime use.

Advantages of Marine Aluminum Hexagonal Bars

Shape Utility: The six-sided profile provides enhanced grip and stability for mechanical joints and assemblies.

Corrosion Resistance: Proven ability to resist saltwater and marine atmosphere corrosion extending service life.

Mechanical Strength: Strong enough to serve demanding load-bearing and wear-resistant applications.

Weldability and Machinability: Easily fabricated using standard marine industry techniques.

Lightweight: Offers significant weight savings compared to steel, improving marine vessel efficiency.

Eco-Friendly: Fully recyclable and sustainable material choice for environmentally conscious marine projects.

Maintenance and Care

Rinse regularly with fresh water to remove salt deposits and marine pollutants.

Use gentle cleaning agents and soft tools to preserve surface finishes.

Inspect periodically for signs of wear, damage, or corrosion, especially near joints and welds.

Apply anodizing or powder coating for enhanced protection in aggressive environments.

Avoid direct contact with dissimilar metals or use proper insulation to prevent galvanic corrosion.

Marine Grade Aluminum Hexagonal Bars combine the inherent benefits of marine alloys with a practical hexagonal profile that offers structural stability, corrosion resistance, and ease of fabrication. Ideal for a wide range of marine applications, these bars provide durable, lightweight solutions that perform reliably in demanding saltwater and salt spray environments.

For custom sizing, alloy selection advice, or technical support, contact our marine metals team dedicated to helping you find the perfect aluminum hexagonal bar for your project needs.