5083 Marine Grade Aluminum Solid Bar for Offshore Vessel Frame Parts

In the demanding environment of offshore vessels, structural integrity, durability, and corrosion resistance are critical factors that determine overall vessel performance and safety. One material that has firmly established itself as a reliable cornerstone for offshore vessel frames is the 5083 marine grade aluminum solid bar. Its unique combination of mechanical properties and excellent resistance to harsh sea conditions make it an exceptional choice for frame parts in this challenging application.

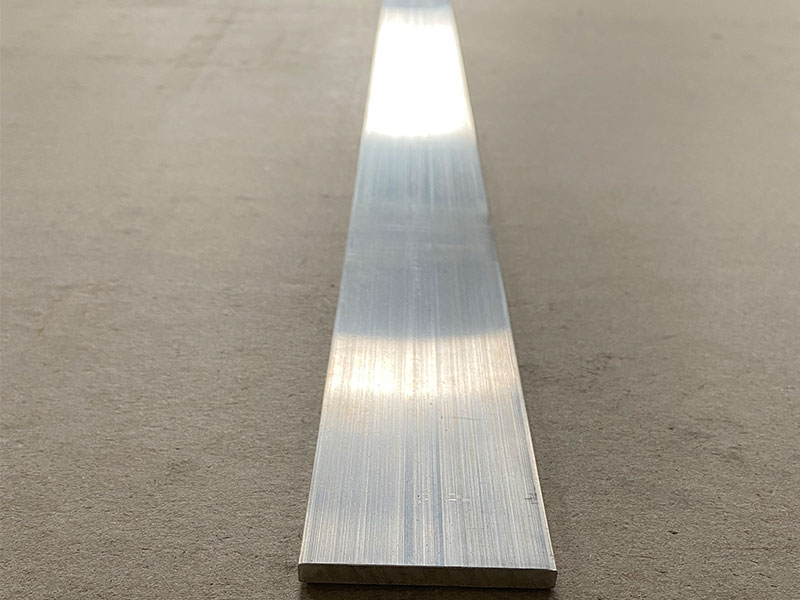

5083 Marine Grade Aluminum Solid Bar

5083 aluminum alloy, primarily alloyed with magnesium (Mg), manganese (Mn), and traces of chromium (Cr), is celebrated for its outstanding resistance to seawater and industrial chemicals, coupled with commendable strength. The “solid bar” refers to the form in which this aluminum alloy is fabricated — a dense, highly machined metal block optimized for precision parts requiring robust load-bearing capacities.

Functions and Applications in Offshore Vessel Frame Parts

The frame parts of offshore vessels — including girders, bulkheads, stringers, stiffeners, and frames — demand materials that can withstand:

- Mechanical stresses from wave impact and vessel motion;

- Extreme saltwater corrosion;

- Fatigue from cyclic loading phenomena;

- Varying temperature ranges.

5083 marine grade aluminum solid bars serve these critical functions in two main capacities:

Structural Integrity & Weight ReductionThanks to their high strength-to-weight ratio, 5083 aluminum bars provide sturdy support without adding excessive mass, essential for efficient vessel buoyancy and fuel economy.

Corrosion Resistance & LongevityAs vessels operate continuously in saltwater, this alloy’s inherent resistance helps minimize degradation, thus extending maintenance intervals and operational life spans of frame parts.

Technical Details and Parameters

Mechanical Properties (Typical for 5083-H112 Temper)

| Mechanical Property | Value | Unit |

|---|---|---|

| Density | 2.66 | g/cm³ |

| Ultimate Tensile Strength | 290 | MPa |

| Yield Strength (0.2% offset) | 145 | MPa |

| Elongation at Break | 12 | % |

| Modulus of Elasticity | 70 | GPa |

These values emphasize a unique balance — sufficient strength for structural longevity and elasticity to absorb dynamic stresses.

Chemical Composition

| Element | Content Range (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others | ≤ 0.05 each, ≤ 0.15 total |

Magnesium primarily provides strength and corrosion resistance. Manganese helps maintain toughness, while chromium reduces brittleness, all synergizing to tackle the offshore exposure profile.

Alloy Tempering and Processing Conditions

The temper of 5083 marine grade aluminum bars significantly affects their performance:

- H112 temper (strain hardened) grants a balance between strength and plasticity without heat treatment, suitable for as-rolled or extruded bars.

- Alternative tempers like H116 and H321 may be employed, especially in marine standards for improved ancillary qualities such as deeper corrosion resistance after welding due to careful strain hardening or stress-relieving.

In manufacturing offshore frame parts, these solid bars undergo precision machining or milling under controlled temperature to preserve dimensional stability, fine surfaces, and performance.

Implementation Standards and Compliance

To ensure material reliability and conformity, 5083 marine grade aluminum solid bars frequently comply with major international standards:

- ASTM B241 / B316 – Specifications for aluminum and aluminum-alloy bars used in marine and structural applications.

- ISO 6362-4 – Aluminium and aluminium alloys — extruded rod/bar, tube and profiles.

- AlMg4.5Mn or 5083 in accordance with EN 485-2.

Beyond testing standards, suppliers ensure thorough certifications reveal alloy chemistry, mechanical testing, ultrasonic checks for defects, and corrosion resistance benchmarks aligned with offshore durability assessments.

Why 5083 Marine Aluminum?

Compared to stainless steel or conventional carbon steels, 5083 aluminum’s advantages in offshore vessel frame applications include:

- Lightweight construction with superior strength metrics

- Resistance to pitting corrosion and stress corrosion cracking suitable for welded marine structures

- Excellent weldability and machinability facilitating complex offshore component fabrication

- Reduced maintenance through inherent corrosion defense

- Resilience across temperature ranges −50 °C to 150 °C, covering functional vessel operating environments

These properties translate into safer, longer-lasting offshore vessels that reduce operational costs without compromising performance.

For offshore vessel engineers and shipbuilders, selecting the right frame material is paramount to project success and safety. The 5083 marine grade aluminum solid bar, engineered with optimal alloy chemistry, tempering, and dimensional characteristics, offers that indispensable blend of corrosion resistance, strength, and durability. Its utilization in rollback, frame braces, support bars, and integral structure components is a testament to its robust capabilities in the aggressive marine environments stretching across oceans and offshore fields.

By choosing 5083 marine aluminum solid bars conforming to strict international standards and processing requirements, the offshore marine industry can ensure resilient vessel frames for decades of rugged service under the waves.

For marine-grade aluminum solutions solidly meeting your vessel frame needs, contact our aluminum experts today to learn about customization, supply lead times, and latest innovations in marine metals engineering.

Related Products

Marine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsRelated Blog

5083 Marine Grade Aluminum Solid Bar for Offshore Vessel Frame Parts

In the demanding environment of offshore vessels, structural integrity, durability, and corrosion resistance are critical factors that determine overall vessel performance and safety.

View Details5083 Marine Aluminum Bar for Marine Equipment Reinforcements

Superior strength, corrosion resistance, and reliability of 5083 Marine Aluminum Bars, specifically engineered for marine equipment reinforcements. Ideal for harsh sea environments, these aluminum bars offer exceptional mechanical properties and long-term

View Details5083 Marine Aluminum Bar for Saltwater Corrosion Resistant Boat Frames

In the demanding marine environment, selecting the right materials for boat frames is vital to ensuring longevity, performance, and safety. Among the myriad of alloys.

View Details5083 Marine Aluminum Hexagonal Bars for Durable Offshore Support Parts

Explore premium 5083 marine aluminum hexagonal bars tailored for offshore support applications. their superior corrosion resistance, alloy composition, mechanical properties, and industry implementation standards.

View Details5083 Marine Grade Aluminum Solid Bar for Boat Hull Reinforcement

In the expansive world of marine construction and engineering, selecting the right materials can make the difference between a resilient vessel and costly structural failures.

View Details5083 Marine Aluminum Hexagonal Bars for High Strength Shipbuilding Materials

When it comes to constructing robust, lightweight, and corrosion-resistant components in the marine industry, 5083 marine aluminum hexagonal bars are an indispensable material.

View Details

Leave a Message