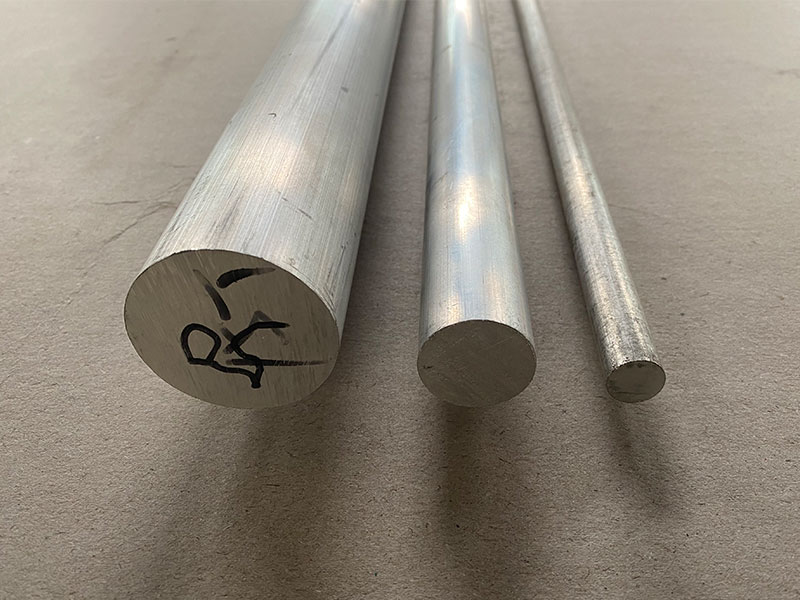

Marine 6082 Aluminum Rod & Bar is a high-performance aluminum alloy product widely used in marine, offshore, and coastal applications that demand excellent strength, corrosion resistance, and versatility. Belonging to the 6xxx series aluminum-magnesium-silicon alloys, 6082 is well-known for its robust mechanical properties combined with outstanding resistance to seawater corrosion, making it a popular choice among shipbuilders, marine engineers, and fabricators looking for a reliable and durable marine-grade material.

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance. The alloy’s outstanding performance in saltwater and marine atmospheres has made it a favored material for structural, mechanical, and functional components used in vessels, offshore platforms, bridges, and other coastal infrastructure.

Manufactured to strict dimensional and quality standards, marine-grade 6082 rods and bars offer superior surface finish, consistent mechanical properties, and a range of sizes and lengths, ensuring compatibility with various marine engineering and fabrication needs.

Chemical Composition

The chemical makeup of 6082 aluminum alloy delivers a powerful blend of strength and corrosion resistance:

| Element | Typical Content (%) |

|---|---|

| Silicon (Si) | 0.7 – 1.3 |

| Magnesium (Mg) | 0.6 – 1.2 |

| Iron (Fe) | ≤ 0.5 |

| Manganese (Mn) | 0.4 – 1.0 |

| Copper (Cu) | ≤ 0.1 |

| Chromium (Cr) | 0.25 – 0.45 |

| Zinc (Zn) | ≤ 0.2 |

| Titanium (Ti) | ≤ 0.1 |

| Aluminum (Al) | Balance |

Mechanical Properties

Marine 6082 Aluminum Rods & Bars, typically supplied in the T6 temper, exhibit impressive mechanical strength combined with moderate ductility:

| Property | Typical Values |

|---|---|

| Tensile Strength (MPa) | 280 – 340 |

| Yield Strength (MPa) | 240 – 300 |

| Elongation (%) | 8 – 12 |

| Brinell Hardness (HB) | 95 – 135 |

| Density (g/cm³) | 2.70 |

Physical and Thermal Properties

Density: Approximately 2.70 g/cm³, offering significant weight savings over steel components.

Thermal Conductivity: Around 180 W/m·K, assisting with heat dissipation in marine machinery and equipment.

Melting Range: 555 – 650 °C, ensuring stability during fabrication and operation.

Electrical Conductivity: Approximately 33% IACS, suitable for marine electrical grounding and conductive applications.

Manufacturing Process

6082 Marine Aluminum Rods and Bars are typically produced through:

Extrusion: Aluminum billets are heated and pushed through shaped dies to form rods and bars with consistent cross-sections.

Heat Treatment: Solution heat-treated and artificially aged (T6 temper) to enhance strength without sacrificing corrosion resistance.

Surface Finishing: Mostly supplied with a mill finish, but anodizing or other surface treatments are available for added corrosion protection and cosmetic appeal.

Cutting & Fabrication: Supplied in standard or customized lengths, rods and bars can be machined, welded, bent, or drilled as required.

Typical Marine Applications

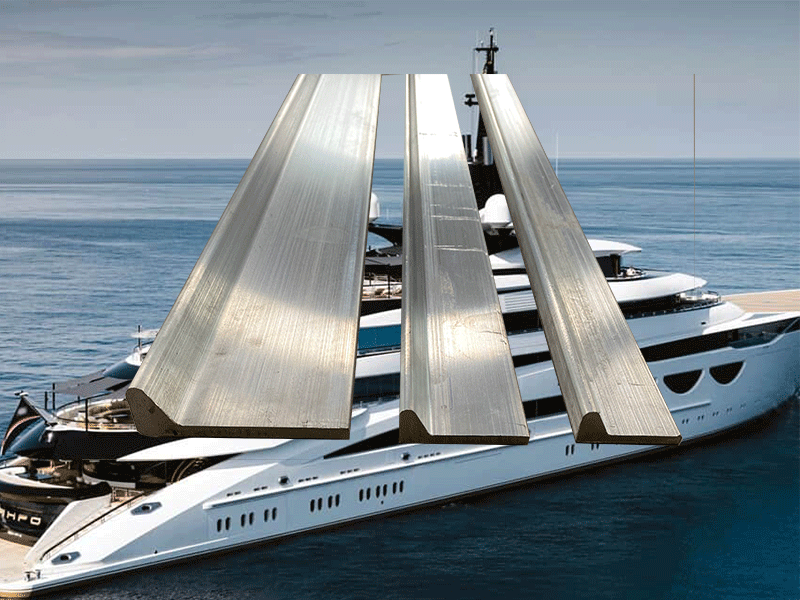

Marine 6082 Aluminum Rods & Bars have widespread applications including:

Shafts, pins, and axles in marine propulsion and steering systems

Structural reinforcements and frameworks for shipbuilding and offshore platforms

Mounting rods and brackets for marine equipment and instrumentation

Hydraulic and pneumatic cylinder components used in marine machinery

Fasteners and connectors designed to withstand saltwater exposure

Rails, supports, and hardware for docks, piers, and coastal infrastructure

Advantages of 6082 Marine Aluminum Rod & Bar

High Strength: Provides structural integrity suitable for load-bearing marine applications.

Superior Corrosion Resistance: Withstands harsh seawater and marine atmospheres, reducing maintenance needs.

Excellent Machinability: Easily cut, turned, drilled, and milled for precision marine component fabrication.

Good Weldability: Compatible with common welding methods including TIG and MIG, preserving corrosion resistance.

Lightweight: Reduces overall vessel and structural weight, enhancing fuel efficiency and handling.

Versatile Sizes and Lengths: Wide range of diameters and lengths meet diverse marine engineering requirements.

Maintenance Practices

To ensure long-term reliability and preserved performance:

Clean Regularly: Use freshwater rinses to remove salt, marine pollutants, and biological deposits.

Avoid Abrasive Cleaners: Utilize mild detergents and soft cleaning methods to protect aluminum surfaces.

Inspect Periodically: Check for scratches, dents, or corrosion, especially near welded joints or fasteners.

Apply Protective Coatings: Consider anodizing or marine-grade paints for extra protection in highly corrosive zones.

Proper Storage: Store in covered, dry areas away from harsh chemical exposure and direct salt spray when inactive.

Marine 6082 Aluminum Rods & Bars offer marine and offshore engineers a robust, corrosion-resistant, and versatile solution for a variety of structural and mechanical applications. Their strong combination of durability, lightweight construction, and fabrication ease makes them a go-to choice for demanding marine environments where longevity and performance cannot be compromised.

For customized sizing, technical support, or order inquiries, contact our expert sales and engineering team dedicated to supporting your marine aluminum needs.