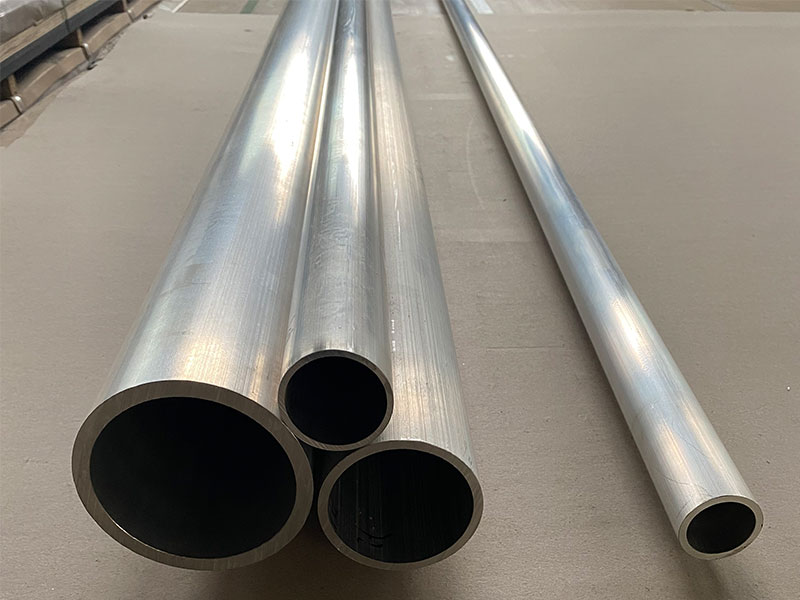

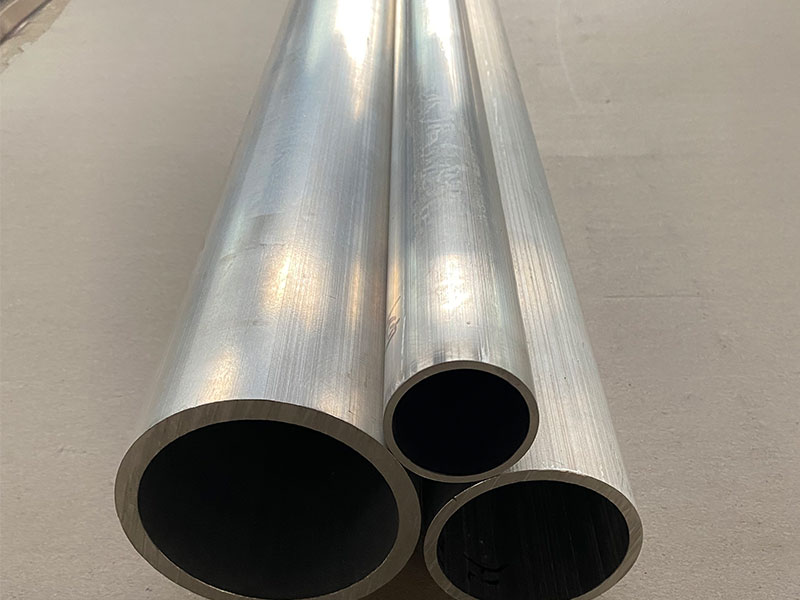

Marine Grade Aluminum Hollow Bars are precision-engineered, lightweight tubular components designed specifically to meet the demands of marine and offshore applications. Crafted from premium marine-grade aluminum alloys, these hollow bars combine excellent corrosion resistance, superior mechanical strength, and versatile fabrication capabilities. Their hollow construction optimizes material usage while maintaining structural integrity, making them an ideal solution for marine engineers, shipbuilders, and offshore fabricators seeking durable, high-performance materials.

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres. The hollow cylindrical profile reduces weight significantly compared to solid bars, permitting greater design flexibility without sacrificing strength or durability.

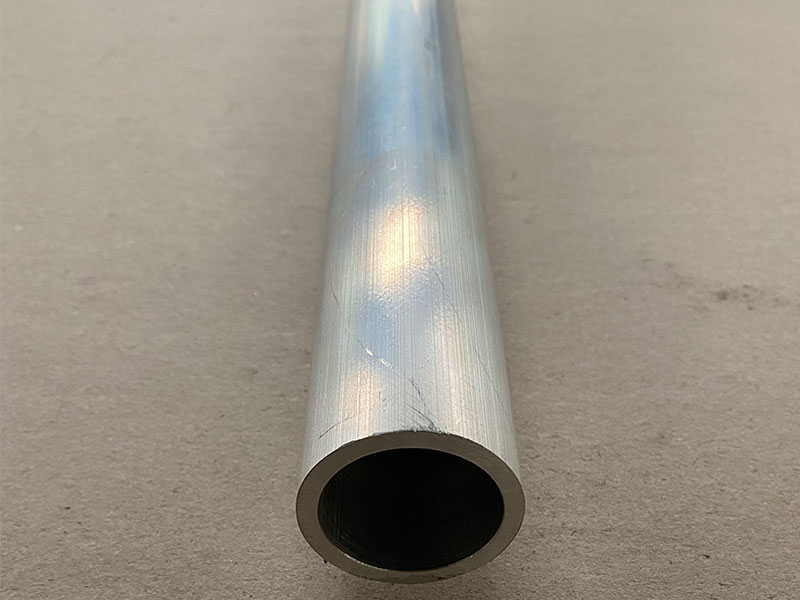

These hollow bars are manufactured using advanced extrusion or precision forming processes, delivering consistent wall thickness, dimensional stability, and smooth surface finishes. They are supplied in a variety of diameters and wall thicknesses to accommodate different marine structural and functional requirements.

Common Marine Aluminum Alloys for Hollow Bars

| Alloy | Composition Highlights | Marine Benefits |

|---|---|---|

| 5083 | Mg 4.0-4.9%, Mn 0.4-1.0%, Cr 0.05-0.25% | Exceptional corrosion resistance and moderate-high strength |

| 5052 | Mg 2.2-2.8%, Cr 0.15-0.35% | Excellent formability, corrosion resistance |

| 6061 | Mg 0.8-1.2%, Si 0.4-0.8%, Cr 0.04-0.35%, Cu 0.15-0.4% | High strength, good machinability, anodizing capability |

| 6082 | Mg 0.6-1.2%, Si 0.7-1.3%, Cr 0.25-0.45% | High strength and good corrosion resistance |

Chemical Composition (Representative)

| Element | 5083 (%) | 5052 (%) | 6061 (%) | 6082 (%) |

|---|---|---|---|---|

| Magnesium (Mg) | 4.0 – 4.9 | 2.2 – 2.8 | 0.8 – 1.2 | 0.6 – 1.2 |

| Silicon (Si) | ≤ 0.4 | ≤ 0.25 | 0.4 – 0.8 | 0.7 – 1.3 |

| Chromium (Cr) | 0.05 – 0.25 | 0.15 – 0.35 | 0.04 – 0.35 | 0.25 – 0.45 |

| Copper (Cu) | ≤ 0.1 | ≤ 0.1 | 0.15 – 0.4 | ≤ 0.1 |

| Iron (Fe) | ≤ 0.4 | ≤ 0.4 | ≤ 0.7 | ≤ 0.5 |

| Manganese (Mn) | 0.4 – 1.0 | ≤ 0.1 | ≤ 0.15 | 0.4 – 1.0 |

| Zinc (Zn) | ≤ 0.25 | ≤ 0.1 | ≤ 0.25 | ≤ 0.2 |

| Titanium (Ti) | ≤ 0.15 | ≤ 0.03 | ≤ 0.15 | ≤ 0.1 |

| Aluminum (Al) | Balance | Balance | Balance | Balance |

Mechanical Properties (Typical, T6 or H321 Tempers)

| Property | 5083-H321 | 5052-H32 | 6061-T6 | 6082-T6 |

|---|---|---|---|---|

| Tensile Strength (MPa) | 300 – 350 | 228 – 271 | 310 – 350 | 280 – 340 |

| Yield Strength (MPa) | 145 – 215 | 103 – 138 | 270 – 300 | 240 – 300 |

| Elongation (%) | 10 – 18 | 10 – 15 | 8 – 12 | 8 – 12 |

| Hardness (Brinell) | 75 – 95 | 60 – 75 | 95 – 115 | 95 – 135 |

| Density (g/cm³) | 2.66 | 2.68 | 2.70 | 2.70 |

Manufacturing Process

Extrusion: Most Marine Aluminum Hollow Bars are produced by extruding heated billets through precision dies to form hollow profiles with uniform wall thickness and accurate dimensions.

Cold Working & Heat Treatment: Depending on alloy and temper, bars may undergo cold working and solution heat treatment followed by artificial aging to achieve required mechanical properties.

Surface Finishing: Typically supplied with mill finish; options include anodizing or powder coating for enhanced corrosion protection and aesthetic appeal.

Cutting & Fabrication: Bars are cut to length and can be machined, welded, or formed to exact specifications for marine applications.

Typical Marine Applications

Shafts and tubular supports in shipbuilding and offshore platforms

Structural columns and framing members requiring high strength and corrosion resistance

Hydraulic and pneumatic cylinder tubes in marine machinery

Mounting pipes and conduits for marine electrical and navigation equipment

Lightweight marine handrails, guardrails, and safety systems

Custom manufactured components requiring hollow tubular profiles with marine durability

Advantages of Marine Aluminum Hollow Bars

Optimized Strength-to-Weight Ratio: Hollow design reduces weight considerably while maintaining load-bearing capacity.

Excellent Corrosion Resistance: Natural oxide layer and alloy composition resist seawater and salt spray corrosion.

Versatile Fabrication: Easily welded, machined, bent, and cut to precise marine standards.

Durability: Resistant to pitting, crevice corrosion, and stress-corrosion cracking common in marine environments.

Environmental Sustainability: Aluminum is fully recyclable, providing an eco-friendly material option for marine engineering.

Reduced Maintenance: Longer service life with low upkeep costs compared to traditional materials.

Maintenance Recommendations

Regular Cleaning: Flush with fresh water frequently to remove salt, algae, and contaminants.

Gentle Cleaning Agents: Use mild detergents and soft brushes to protect surfaces.

Inspect Joints and Welds: Monitor for physical damage, corrosion, or fatigue.

Surface Protection: Apply anodizing or marine-grade coatings if additional protection is required in aggressive environments.

Proper Handling: Avoid contact with dissimilar metals unless insulated to prevent galvanic corrosion.

Marine Grade Aluminum Hollow Bars offer a perfect combination of corrosion resistance, mechanical strength, and lightweight design tailored for seawater and coastal environments. Their hollow profile delivers material efficiency and design flexibility, making them invaluable for structural and functional marine applications.

For custom sizes, alloy selection, or detailed technical support, contact our experienced sales and engineering team to ensure you receive the ideal marine aluminum hollow bars for your next project.