Marine Aluminum Customized Shapes for Custom Offshore Equipment Frame Designs

In the demanding environment of offshore operations, material performance can make or break the reliability of equipment frames. At the heart of the industry's evolving requirements, marine aluminum customized shapes have emerged as a preferred engineering solution for custom offshore equipment frame designs.

Marine Aluminum in Offshore Equipment Frames

Marine aluminum represents a specialized set of aluminum alloys designed to uphold mechanical properties such as strength, corrosion resistance, and fabrication flexibility in marine and offshore conditions. When custom-shaped into frames for offshore equipment, marine aluminum’s properties enhance durability against sea water erosion and structural fatigue resulting from dynamic loading.

Working with marine-grade aluminum alloys for custom offshore equipment frames is a fascinating blend of artistry and engineering. We're not just cutting and welding metal; we're crafting the backbone of structures that will face brutal saltwater corrosion, extreme weather, and potentially immense loads. The customization aspect is crucial – a one-size-fits-all approach simply won't cut it in this industry. Each frame design demands unique considerations based on the specific equipment it houses, the environmental conditions it'll encounter, and the client's performance requirements. This often means working closely with engineers and designers, translating their blueprints into achievable, cost-effective solutions while maintaining the integrity and longevity of the final product. We're constantly pushing the limits of what's possible with the material, new welding techniques, and refining our fabrication processes to meet ever-more demanding specifications.

My personal insight comes from seeing firsthand the impact of our work. It’s incredibly rewarding to know that the precisely-cut and welded aluminum shapes we produce form the robust foundations of crucial offshore platforms, research vessels, and specialized equipment. The challenges are considerable – from sourcing the right alloy to ensuring impeccable surface finishes to prevent corrosion – but the results speak for themselves. The satisfaction of seeing a completed frame, knowing it's built to withstand the harshest conditions and contribute to the success of a complex offshore operation, is a feeling unmatched in any other manufacturing sector. It'

Why Custom Shapes?

Unlike standard profiles, customized aluminum shapes offer design flexibility matching unique offshore equipment patterns — critical when conventional beams or sections cannot fully satisfy spatial or load distribution requirements. Leveraging advanced extrusion and fabrication techniques, tolerances can be premium-controlled, enabling intricate corner radii, upturned flanges, and integrated mounting points.

Technical Parameters of Marine Aluminum for Offshore Frames

When designing offshore equipment frames utilizing marine aluminum, several parameters affect structural integrity and longevity.

| Parameter | Specification | Purpose |

|---|---|---|

| Alloy Type | 5083-H116 or 5383-O | Excellent corrosion resistance and strength in seawater |

| Temper Condition | H116 or H321 | Enhanced resistance to stress corrosion cracking |

| Yield Strength | Min. 215 MPa (5083-H116) | Maintains rigidity against heavy offshore loads |

| Elongation | Minimum 12% | Allows slight deformation under dynamic stress, avoiding brittle fracture |

| Density | ~2.66 g/cm³ | Lightweight property reduces energy consumption for moving equipment |

| Thermal Expansion | 23.7 x 10^-6 /°C | Ensures dimensional stability over temperature fluctuations |

The selection of the 5083-grade marine aluminum alloy is pivotal. Unlike 6061 or 7075 series common in general engineering, 5083 offers exceptional corrosion resistance due to its high magnesium content (about 4.0%-4.9 % Mg). This feature reduces galvanic corrosion and pitting — critical factors in marine environments.

Alloy Tempering and Metallurgical Considerations

Temper designations specify the mechanical processing and thermal treatment the aluminum undergoes after extrusion/purification:

- H321 Temper: Denotes strain-hardened (cold worked) and stabilized aluminum. Characterized by improved stress corrosion-cracking resistance, critical under cyclic offshore loads.

- H116 Temper: A stabilized temper specifically for 5xxx series marine-grade alloys achieved via low-temperature heat treatment. It helps maintain corrosion-resistant properties for welding-heavy offshore equipment frame fabrications.

These tempers indirectly affect hardness, tensile strength, yield strength, and fracture toughness, thereby finely tuning the frame’s mechanical load-bearing threshold.

Implementation Standards and Testing Protocols

Conformance to international and industry standards ensures marine aluminum customized shapes satisfy offshore equipment safety requirements:

- ASTM B209 / B221: Define aluminum and aluminum-alloy sheet/plate and extrusions specs.

- ISO 6361: Pertains to marine-grade aluminum sheet and plate, comprehensively stipulating testing guidelines for chemical and mechanical properties.

- DNVGL-OS-C502: Classification for marine aluminum structures detailing design, material parameters, and maintenance operations.

- AWS D1.2: Specification for Aluminum Welding essential in fabricating seamless offshore frames.

Dimensional inspection via Coordinate Measuring Machines (CMMs) guarantees strict adherence within ±0.2 mm tolerances for custom shapes, ensuring perfect integration with existing systems.

Chemical Composition Table of Typical Marine Aluminum Alloy 5083 (Example)

| Element | Content (%) | Remarks |

|---|---|---|

| Mg | 4.0 – 4.9 | Enhances corrosion resistance and strength |

| Mn | 0.4 – 1.0 | Improves strength |

| Cr | 0.05 – 0.25 | Resists grain growth, improving toughness |

| Zn | ≤ 0.25 | Kept low to avoid reduced corrosion resistance |

| Fe | ≤ 0.4 | Minimized impurity |

| Si | ≤ 0.4 | Kept low to avoid brittleness |

| Cu | ≤ 0.1 | Minimal to maintain marine properties |

Distinctive Advantages of Customized Marine Aluminum Frames in Offshore Applications

- Corrosion Resistance at Immersed Interfaces: Combats saltwater and humidity-induced degradation due to magnesium enrichment and protective oxide layer formation.

- Weight-to-Strength Ratio: Aluminum's lightness reduces platform mass yield lower transportation/floating costs when modular equipment mobilization is needed.

- Fabrication Flexibility: Convert pooled ingots/billets into bespoke molded cross-sections suiting unconventional load patterns—a monumental asset where design versatility impacts operational efficiency.

Related Products

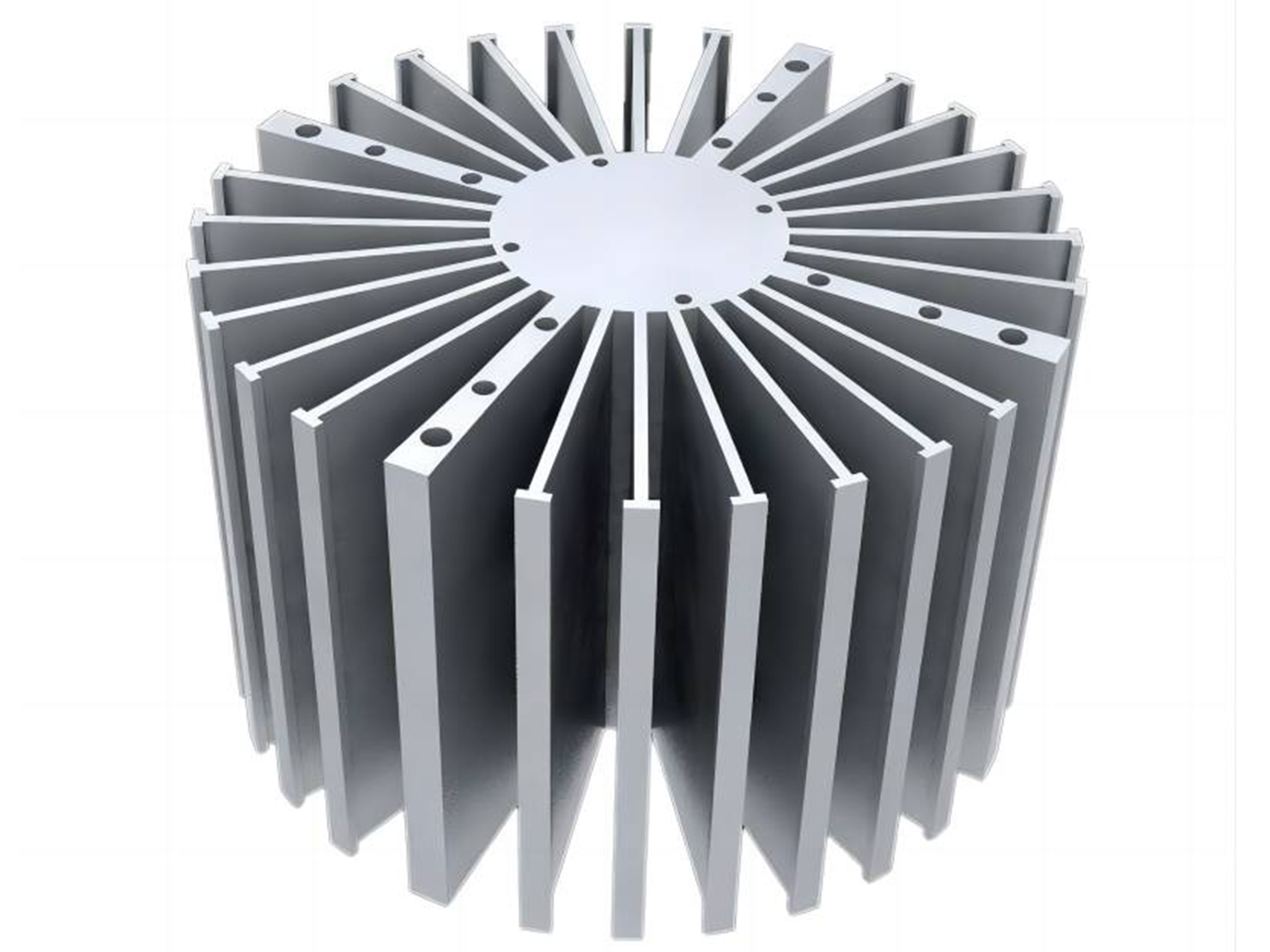

Marine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsMarine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsRelated Blog

Marine Aluminum Fencing and Railings for Custom Boat Deck Guardrails

Marine Aluminum Fencing and Railings: The Ultimate Choice for Custom Boat Deck GuardrailsWhen it comes to constructing custom boat deck guardrails, marine aluminum fencing and railings are emerging as the industry’s top choice.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability.

View Details6061 Marine Aluminum Heat Sink Profile for Custom Boat and Ship Engine Cooling

Explore the superior cooling efficiency of 6061 Marine Aluminum Heat Sink Profiles, engineered for custom boat and ship engines. detailed specifications, temper types, chemical properties, standards compliance, and advanced corrosion resistance features o

View Details6063 Marine Aluminum Heat Sink Profile for Seawater Resistant Cooling Systems for Boats

When it comes to boats and marine systems, efficient heat dissipation combined with exceptional corrosion resistance is crucial for reliable operations.

View DetailsMarine Aluminum Customized Shapes for Marine Engineering Custom Fabrications

High-quality marine aluminum customized shapes tailored for marine engineering custom fabrications. Enhance durability, corrosion resistance, and structural integrity with precision-engineered aluminum solutions designed specifically for maritime applicat

View Details5052 Marine Aluminum Customized Shapes for High Strength Offshore Platforms

Superior qualities of 5052 Marine Aluminum, a high-strength material ideal for customized shapes used in offshore platforms. Learn about its key features, applications, and technical specifications.

View Details

Leave a Message