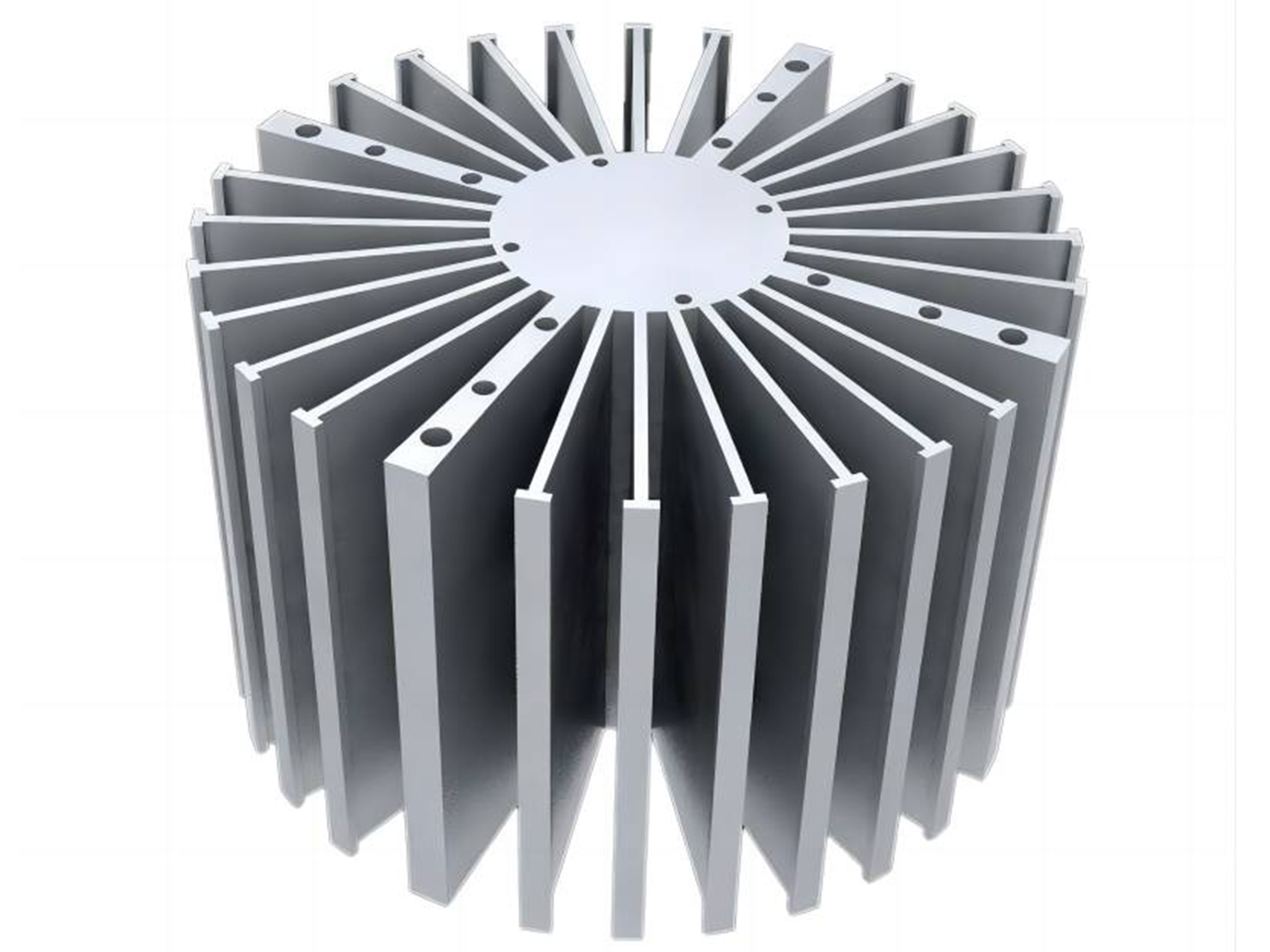

6063 Marine Aluminum Heat Sink Profile for Seawater Resistant Cooling Systems for Boats

When it comes to boats and marine systems, efficient heat dissipation combined with exceptional corrosion resistance is crucial for reliable operations. Among the advanced materials gaining traction in marine cooling applications is the 6063 marine aluminum heat sink profile — a specially engineered solution designed to stand up to the rigors of saltwater environments while delivering optimal thermal management.

6063 Marine Aluminum: Why It Is Ideal for Marine Heat Sinks

6063 aluminum alloy is often referred to as an architectural or structural alloy, valued for its excellent surface finish and strong resistance to corrosion, especially in marine conditions. Let's examine why 6063 aluminum heat sink profiles are the preferred choice for seawater resistant cooling systems:

Corrosion Resistance: The marine grade 6063 exhibits reinforced resistance against saltwater fouling and oxidation, primarily due to its balanced composition of magnesium and silicon. This makes it highly resistant to corrosion that would normally degrade other metals in marine environments.

Thermal Conductivity: With thermal conductivity typically around 201 W/m·K, the 6063 alloy dissipates heat effectively, acting as an excellent medium to transfer thermal energy away from electronics or engine components exposed to heat buildup.

Mechanical Strength & Surface Finish: Tempered in states like T5 or T6, 6063 aluminum transforms into a tough yet machinable material, permitting intricate extrusion designs that boost surface area — a critical aspect of cost-effective heat sink functionality.

The Functional Role of 6063 Marine Aluminum Heat Sink Profiles in Cooling Systems

Heat sinks in marine cooling systems must manage rapid and fluctuating heat loads consistently within wave-fatigue and corrosion-laden settings. The structural purity and optimized heat dissipation of a 6063 aluminium heat sink profile bring several advantages:

1. Heat Dissipation in Compact Spaces

Extruded profiles allow designers to significantly expand surface area through fins and channels. Increased surface area improves rate of convective cooling even when a compact design is mandatory — such as within limited engine compartments or on circuit boards of marine equipment.

2. Design Versatility and Integration

The high extrusion quality and machinability open doors to customized profile shapes that integrate seamlessly within pump housings, water-cooled manifolds, or electronic enclosures. This compatibility facilitates efficient thermal pathways from sensitive components to seawater-buffered surfaces.

3. Corrosion Protection in Aggressive Seawater Exposure

Unlike other metals vulnerable to galvanic corrosion, marine grade 6063 aluminum can form a passive oxide layer acting as a natural barrier against environmental degradation. Combined with anodizing steps or protective coatings, corrosion resistance ensures longer service intervals and reduces vessel maintenance costs.

Detailed Chemical Composition of 6063 Marine Aluminum

Specific alloy chemistry defines the characteristic performance of the marine aluminum heat sink profile. Below is the typical composition (% by weight) outlined according to ASTM B221 and marine vessel construction standards:

| Element | Percentage (%) |

|---|---|

| Silicon (Si) | 0.2 – 0.6 |

| Iron (Fe) | ≤ 0.35 |

| Copper (Cu) | ≤ 0.1 |

| Manganese (Mn) | ≤ 0.1 |

| Magnesium (Mg) | 0.45 – 0.9 |

| Chromium (Cr) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.1 |

| Titanium (Ti) | ≤ 0.1 |

| Aluminum (Al) | Balance (~96+) |

Standard Tempering Conditions and Mechanical Parameters

The functional properties depend strongly on temper grades intended for dynamic marine settings:

| Temper | Description | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| T5 | Cooled from extrusion, artificially aged | 160 - 210 | 120 - 180 | 8 – 12 |

| T6 | Solution heat treated and artificially aged | 205 - 260 | 180 – 230 | 8 – 12 |

In marine cooling systems, T5 temper is often favored for its balanced machinability and corrosion resistance, especially advantageous where complex extrusion forms are mandatory.

Implementation Standards for Marine Applications

The extrusion profiles used to fabricate heat sinks strictly conform to marine industry specifications such as:

ASTM B221: Specification for aluminum and aluminum-alloy extruded bars, rods, wires, profiles, and tubes ensuring consistent dimensions and defects-free structural profiles.

ISO 15590-1: Extrusion of aluminum alloys—particularly applicable to applications requiring high corrosion resistance and mechanical reliability under marine loads.

MIL-DTL-24768: For marine electronic equipment housing which regulates thermal conduction properties.

Typical Applications in Boating Cooling Systems

6063 marine aluminum heat sinks deliver equation-specific solutions for heat control:

Saltwater Radiator Fins: Utilizing complex, multi-channel extrusions, 6063 profiles are manufactured into fin sets aimed at dissipating engine heat via saltwater counterflow.

Electronics Cooling Modules: In sensitive marine GPS units, depth finders, or communication systems operating aboard ships, compact heat sinks built from 6063 aluminum sustain performance under heavy thermal and salinity stress.

Water Cooling Manifold Designs: Cooling blocks behind marine propulsion engines use extrusion profiles with enhanced fin design manufactured precisely to 6063 specifications to support continuous operations in saline waters.

Final Thoughts

The 6063 marine aluminum heat sink profile embodies an ideal balance of mechanical resilience, corrosion resistance, and thermal management, tailored specifically for the harsh conditioning of seawater exposed cooling systems in marine vessels. Its well-characterized chemical composition and versatile temper conditions deliver a proven framework for high-efficiency thermal control essential within modern boating technologies. Whether for electronic enclosures, heat exchangers, or specialized radiator fins — leveraging the benefits of marine grade 6063 aluminum alloy maximizes reliability and reduces maintenance challenges essential to seamless maritime operations.

If you're seeking durable, seawater-ready cooling components for your boat, choosing 6063 marine aluminum heat sink profiles guarantees unmatched operational integrity influenced by science, designed with naval craftsmanship in mind.

Related Products

Marine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsMarine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsMarine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsRelated Blog

6063 Marine Aluminum Heat Sink Profile for Coastal Platform Electronics

Advantages of 6063 marine aluminum heat sink profiles, engineered to provide superior thermal management and corrosion resistance for coastal platform electronics. Ideal for harsh maritime environments.

View Details6063 Marine Aluminum Heat Sink Profile for Seawater Resistant Cooling Systems for Boats

When it comes to boats and marine systems, efficient heat dissipation combined with exceptional corrosion resistance is crucial for reliable operations.

View Details6063 Marine Aluminum Heat Sink Profile for Efficient Cooling of Offshore Equipment

In the marine and offshore industry, equipment reliability and performance hinge on effective thermal management solutions. Heat dissipation is a critical factor influencing the longevity and efficiency of sensitive offshore electronics and machinery.

View DetailsMarine Aluminum Fencing and Railings for Durable Boat Deck Guardrails

OverviewMarine aluminum fencing and railings are purpose-designed alloy systems used for guardrails, handrails, stanchions, and safety barriers on boats, docks, marinas, and waterfront properties.

View Details

Leave a Message