Marine Aluminum Fencing and Railings for High Strength Boat Deck Safety Barriers

When it comes to ensuring safety on boat decks, the choice of fencing and railing materials plays a critical role. Marine aluminum fencing and railings have emerged as the premier solution for high strength, corrosion-resistant, and lightweight safety barriers in marine environments.

Marine aluminum fencing and railings serve as the primary safety barrier on boat decks, protecting passengers and crew against accidents such as falls overboard, slips, and other hazards lumbering unaided marine vessels pose. Their structural integrity under various weather conditions, exposure to corrosive saltwater, along with aesthetic finishes bring distinct advantages absent in traditional materials such as steel or wood.

Features of Marine Aluminum Fencing and Railings

1. Superior Corrosion Resistance

Marine aluminum alloys inherently resist corrosion caused by seawater and humidity, greatly reducing maintenance costs. A high concentration of magnesium in the alloy enhances oxide layer formation, preventing rust without grazing the surface treatments such as anodizing or powder coating.

2. High Strength to Weight Ratio

Aluminum alloys provide an excellent combination of lightweight and drop-forged strength, which ensures the fencing can withstand deformation and high loads without incurring weight penalties. This reduces the overall structure weight and strain on the boat simultaneously.

3. Low Maintenance and Long Lifespan

Unlike heavier steel or susceptible wooden materials, aluminum railings do not require frequent fixes like repainting, grinding, or replacement due to rot or rust. Typical maintenance is limited to simple washing and inspections.

4. Custom Fabrication & Aesthetic Finishes

Marine aluminum fencing can be easily extruded or welded into various designs while accommodating color anodizing or powder coating options that uphold both protection and deck aesthetic enhancements.

5. Non-Magnetic Properties

Minimizing electromagnetic interference near sensitive marine electronics and instruments is achievable as aluminum’s non-magnetic characteristics ensure cumulative enigmatic impacts and safe environments within navigation-intensive vessels.

Chemical Composition & Typical Alloy Specifications

Marine aluminum fencing and railing products predominantly utilize the 5xxx series aluminum alloys, given their superb marine corrosion resistance. Below is a typical example alloy known for railing construction:

Working with marine-grade aluminum, specifically in the context of boat deck fencing and railings, is a constant balancing act between strength, corrosion resistance, and weight. We don't just pour aluminum; we're crafting safety. The unique challenges lie in meeting stringent maritime standards. A minor design flaw or a seemingly insignificant compromise on material quality could have disastrous consequences. I've seen firsthand how the alloy composition—the precise ratios of magnesium, silicon, and other elements—directly impacts the final product's tensile strength and fatigue resistance, crucial elements when dealing with the relentless pounding of sea spray and the dynamic forces at play on a vessel. We meticulously test every batch, analyzing its yield strength, elongation, and corrosion resistance in simulated marine environments to ensure it surpasses industry benchmarks.

Beyond the material science, the fabrication process itself requires precision. Welding techniques are critical; improper welds create stress points, potentially jeopardizing the structural integrity of the railing. Our team is highly skilled in TIG welding, ensuring strong, clean welds that withstand constant exposure to salt and moisture. Furthermore, the design considerations are equally important. The overall geometry, spacing of vertical bars, and handrail height aren't arbitrary; we carefully calculate these parameters to prevent accidental falls, taking into account the anticipated loads and potential impacts. It’s incredibly rewarding to know we’re contributing to safer and more robust boats, playing a part in protecting lives and equipment at sea.

| Element | Aluminum Alloy 5083 Composition (Wt%) | Properties Gained |

|---|---|---|

| Aluminum (Al) | Balance | Lightness and corrosion resistance |

| Magnesium (Mg) | 4.0 - 4.9 | Enhances strength and corrosion resistance |

| Manganese (Mn) | 0.4 - 1.0 | Grain structure control and strength |

| Chromium (Cr) | 0.05 - 0.25 | Improves toughness and resistance to grain boundary corrosion |

| Iron (Fe) | ≤ 0.4 | Minor impurities tolerated |

| Others | ≤ 0.15 combined | Trace of other strengthening alloying elements |

Mechanical Properties at a Glance

| Mechanical Property | Value | Unit |

|---|---|---|

| Tensile Strength | 290 - 350 | MPa |

| Yield Strength (0.2% offset) | 145 - 215 | MPa |

| Elongation at Break | 12 - 18 | % |

| Modulus of Elasticity | 70 | GPa |

| Density | 2.66 | g/cm³ |

Note: Values may vary depending upon the exact alloy temper and post-processing treatments.

Applications on Boat Deck Safety Barriers

1. Guard Railings & Balustrades

Marine aluminum fencing is widely used for perimeter railing to prevent accidental falls from open decks, stairs, and catwalks, offering secure handholds and safety without influencing vessel balance due to its lightness.

2. Safety Barriers & Partition Fences

These aluminum fences not only designate secure zones but also provide quick installation barriers against swinging rigging, pathways, and machinery hazards with resilient yet courteous compliance to marine safety norms.

3. Access Gates and Stair Rails

Custom aluminum railings bridge the necessities of durable, weatherproof gates and consistent stair railing solutions for internal deck use, especially in high-traffic or crew recreational spaces.

4. Fishing Rod Holders and Storage Racks

Some fencing designs are integrated with auxiliary marine structures allowing multiple uses that include rod sock slots, kayak Racks or RMS Components to handle cargo restraints and storage.

Why Choose Marine Aluminum for Your Boat Deck Safety?

- extends the service life of safety installations reducing frequent investment cycles;

- minimizes structural retrofit costs attributed to lightweight attributes optimizing fuel performances;

- fabricates complex anodized/powder coated surface branding customized Octtable order designs thereby expanding aesthetic options at competitive pricing;

- meets marine safety certifications reliant on weather, autocomplete reef & voluntary haze factors grape continuous asset quarantine regimes;

Related Products

Marine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

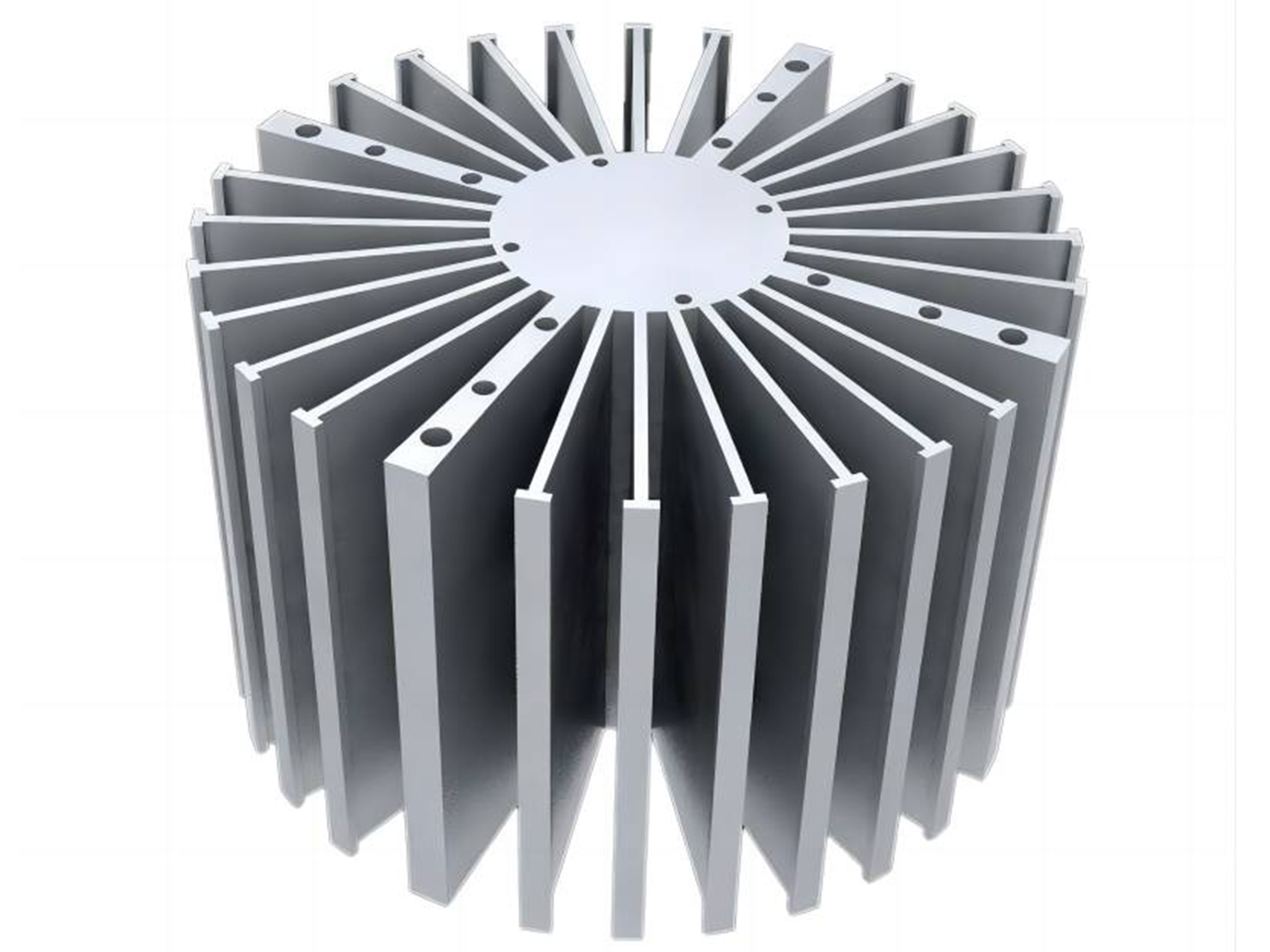

View DetailsMarine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsRelated Blog

5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability.

View DetailsMarine Aluminum Heat Sink Profile for Cooling Offshore Marine Electrical Systems

In the ever-demanding offshore marine environment, electrical systems are subjected to extreme conditions—saltwater corrosion, temperature fluctuations, mechanical stresses, and continuous operation.

View Details5083 Marine Aluminum Customized Shapes for Coastal Infrastructure Design and Build

When it comes to the demanding environments of coastal infrastructure design and build, 5083 Marine Aluminum continues to solidify its leadership with exceptional strength and corrosion resistance.

View Details6063 Marine Aluminum Heat Sink Profile for Seawater Resistant Cooling Systems for Boats

When it comes to boats and marine systems, efficient heat dissipation combined with exceptional corrosion resistance is crucial for reliable operations.

View Details5083 Marine Aluminum Fencing and Railings for Custom Coastal Guardrails

5083 marine aluminum is a widely used alloy for coastal guardrails, fencing, and railings because it combines excellent corrosion resistance in seawater environments, strong mechanical properties, and good weldability.

View DetailsMarine Aluminum Customized Shapes for Marine Engineering Custom Fabrications

High-quality marine aluminum customized shapes tailored for marine engineering custom fabrications. Enhance durability, corrosion resistance, and structural integrity with precision-engineered aluminum solutions designed specifically for maritime applicat

View Details

Leave a Message