5052 Marine Aluminum Fencing and Railings for Durable Offshore Vessel Guardrails

When it comes to constructing durable and reliable guardrails on offshore vessels, 5052 marine aluminum stands out as a premier choice. This aluminum alloy is widely preferred for fencing and railing systems in marine environments due to its excellent corrosion resistance, superior strength, and lightweight nature.

Why 5052 Marine Aluminum?

Choosing the right material for offshore vessel guardrails and fencing requires considering the harshness of the marine environment-constant exposure to saltwater, high humidity, and mechanical wear. 5052 marine aluminum exhibits outstanding corrosion resistance against seawater and salt spray, which minimizes maintenance costs and extends the lifespan of railings far beyond traditional metals like stainless steel or carbon steel.

The alloy's balanced strength-to-weight ratio reduces overall vessel weight, translating into fuel efficiency and better vessel handling-crucial factors for marine operations.

Primary Functions of 5052 Aluminum Guardrails on Offshore Vessels

Offshore vessel guardrails are safety-critical components designed to:

- Prevent accidental falls: Offering robust physical barriers that protect crew and passengers on decks.

- Enhance operational safety: Ensuring compliance with maritime safety standards.

- Provide long-lasting structural integrity: Withstand waves, impact, and continuous exposure to saline environments without significant degradation.

- Facilitate maintenance and inspection: The aluminum surface resists corrosion, making visual inspections straightforward.

Without reliable guardrails, the risk of injury in turbulent marine conditions increases significantly.

Common Applications in the Marine Industry

The versatility of 5052 aluminum fencing and railings means it finds extensive use in:

- Offshore oil and gas platform guardrails: Ensuring the safety of personnel working near open decks.

- Commercial fishing vessels: Lightweight protective barriers that do not add compromising weight.

- Research vessels and marine labs: Corrosion-resistant solutions with minimal ecological impact.

- Passenger ferries and workboats: Providing long-lasting protection while maintaining aesthetic appeal.

- Marine docks and ports: Modular fencing solutions that face constant exposure to seawater.

Regardless of the vessel type, where safety and durability coincide, 5052 aluminum is often the optimal fencing material.

Aluminum Alloy Temper Designations

Proper alloy tempering conditions influence the mechanical properties relevant to fencing manufacturability and performance. The commonly used tempers for 5052 aluminum in marine fencing are:

| Temper | Description | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|---|

| H32 | Strain hardened and stabilized | 228-281 | 193-241 |

| H34 | Strain hardened and stabilized with more cold work | 260-305 | 222-271 |

| H351 | Strain hardened and partially annealed | 228-281 | 183-228 |

These tempers balance ductility and strength, enabling railings that are sturdy yet formable.

Chemical Composition of 5052 Marine Aluminum

The corrosion resistance and weldability properties derive from the alloy's chemical constituents, carefully balanced as below:

| Element | Weight % |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Iron (Fe) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Manganese (Mn) | ≤ 0.1 |

| Silicon (Si) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.1 |

This composition enables enhanced marine durability while affording ease of fabrication.

Essential Mechanical Properties

Controlled mechanical properties impart toughness and resistance against structural failures vital for offshore environments:

| Property | Value |

|---|---|

| Tensile Strength | 220 - 330 MPa |

| Yield Strength | 125 - 260 MPa |

| Elongation (%) | 10 - 20 |

| Hardness (Brinell) | 70 - 85 HB |

| Density | 2.68 g/cm³ (lightweight) |

Implementation Standards for 5052 Marine Aluminum Fencing

To assure reliability and compliance, 5052 aluminum fencing and railings typically meet stringent global classifications and specifications such as:

| Standard | Description |

|---|---|

| ASTM B209 | Aluminum and aluminum-alloy sheet and plate |

| ASTM B928 | Standard Specification for Aluminum-Alloy 5000 Series Extruded Bars and Rods |

| NAVSEA (US Navy) | Approvals for marine applications |

| ISO 12215 | Small craft construction standards for hulls and decks including railings |

| DNV / GL Certification | Guidelines for offshore structural safety |

Products correlating with these standards ensure quality materials that fulfill maritime longevity and operational safety.

Advantages of Using 5052 Aluminum for Railings and Fencing on Offshore Vessels

- High Corrosion Resistance: Longer service life under consistent saline spray exposure compared to steel.

- Easy to Fabricate: Can be cut, welded, and shaped efficiently on-site.

- Lightweight Construction: Decreases top-side weight to improve ship stability and performance.

- Low Maintenance: Corrosion resistance reduces cleaning and repair frequency.

- Aesthetic Appeal: Bright finish that persists for a clean, professional look.

- Excellent Fault Tolerance: More resistant to cracking or impact damage than many aluminum alloys.

Considerations for Designers and Fabricators

Strong partnerships between engineers, vessel builders, and material suppliers cannot overlook principles such as:

- Online evaluation of tensile/yield strengths for safety factors.

- Utilization of appropriate weld processes for 5052 alloys.

- Use of protective surface finishes or anodizing if needed.

- Proper inspection procedures aligned with marine authority guidelines.

- Flexibility to adopt changes in memo temper for specialized performance treatments as conditions require.

Related Products

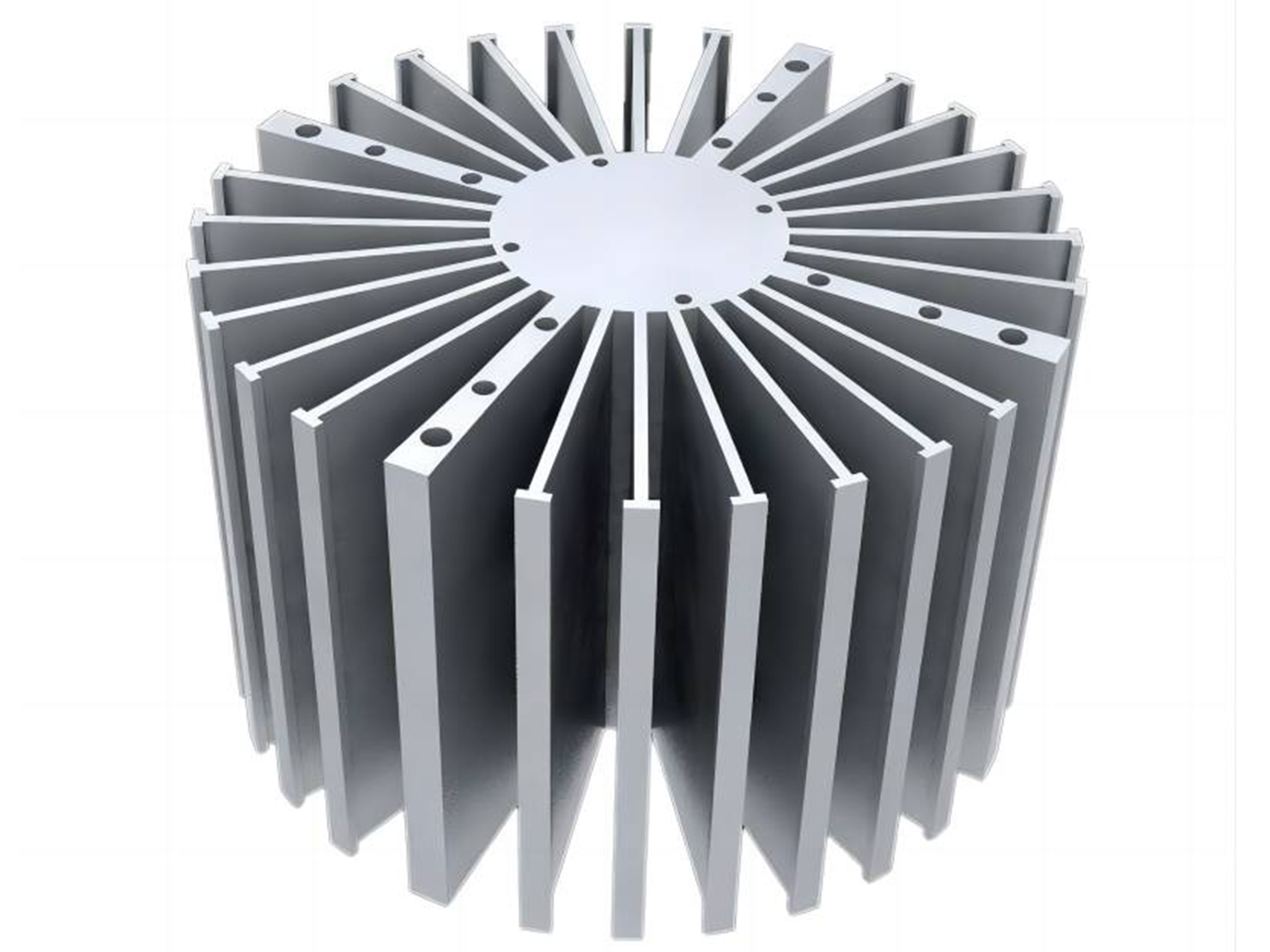

Marine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsMarine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsRelated Blog

5052 Marine Aluminum Fencing and Railings for High Strength Offshore Platform Guardrails

In marine and offshore environments, the demand for materials that combine excellent strength, corrosion resistance, and durability is paramount. 5052 marine aluminum is a preferred choice for high-performance fencing and railings.

View Details5052 Marine Aluminum Customized Shapes for High Strength Marine Engineering Components

Aluminum has emerged as a crucial material in marine engineering due to its combination of lightweight, corrosion resistance, and high strength. The 5052 alloy series, particularly, provides an excellent solution for challenging marine environments.

View Details5052 Marine Aluminum Fencing and Railings for Custom Marine Deck Safety

When it comes to designing secure and durable marine environments, choosing the right material for fencing and railings is key. Among the most popular choices today is 5052 marine aluminum, which is well-regarded in the shipbuilding.

View Details5052 Marine Aluminum Fencing and Railings for Saltwater Proof Marine Railings

When it comes to marine-grade fencing and railings, durability, corrosion resistance, and strength are paramount. The challenging marine environment, especially exposure to saltwater, demands materials that can withstand constant wear and corrosion.

View Details5052 Marine Aluminum Fencing and Railings for Saltwater Proof Marine Railing Systems

When it comes to marine applications, durability, corrosion resistance, and strength are non-negotiable. One material that stands out as a superior choice for fencing and railing systems on ships, docks, and coastal structures is 5052 Marine Aluminum.

View DetailsMarine Aluminum Fencing and Railings for Durable Boat Deck Guardrails

OverviewMarine aluminum fencing and railings are purpose-designed alloy systems used for guardrails, handrails, stanchions, and safety barriers on boats, docks, marinas, and waterfront properties.

View Details

Leave a Message