5052 Marine Aluminum Angles for Custom Boat Deck Engineering

5052 Marine aluminum angles are a go-to structural shape for boat deck builds where corrosion resistance, weldability, and dependable strength matter more than flashy specs. In custom deck engineering, angles do the quiet work: stiffening hatches, framing deck edges, backing fasteners, supporting consoles, and keeping panels from "oil-canning" under foot traffic.

Built from AA 5052 (Al-Mg), these angles are designed for saltwater reality-spray, bilge humidity, galvanic risks, and the inevitable scratches that expose fresh metal. When you want a lightweight reinforcement that fabricates cleanly and stays stable over time, 5052 angles are a practical, marine-proven choice.

Why 5052 Aluminum Angles Work So Well on Boat Decks

performance advantages

| Feature | What it means in deck engineering | Why customers care |

|---|---|---|

| Excellent saltwater corrosion resistance | Magnesium-based alloy chemistry forms a durable oxide layer | Longer service life with less pitting and fewer "white rust" headaches |

| High weldability | Compatible with common marine welding practices (MIG/TIG) | Faster fabrication, easier repairs, fewer cracked joints |

| Light weight vs. steel | Low density with useful strength | Easier handling, less hull weight, better fuel economy |

| Good formability | Can be cut, drilled, notched, and fitted efficiently | Clean custom installs, fewer reworks during layout |

| Solid fatigue behavior in real structures | Handles vibration and wave-induced cycling better than many brittle materials | Reduced risk of loosening or fatigue-related distortion |

Typical Uses in Custom Boat Deck Engineering

5052 angles show up wherever a deck needs a clean, stiff edge or a strong corner connection.

| Application area | How the angle is used | Common benefit |

|---|---|---|

| Deck perimeter framing | Edge stiffeners, toe-kick reinforcement, rub-rail backing | Straighter deck lines, stronger edges |

| Hatch and access openings | Frame rings, corner reinforcement, hinge backing | Prevents deformation around cutouts |

| Console and seat bases | Brackets, mounting rails, gusset-style supports | Better load distribution, fewer stress points |

| Under-deck stiffening | Longitudinal or transverse stiffeners | Reduces panel flex and noise |

| Non-slip deck panel support | Angle "ledges" to carry removable panels | Easy maintenance access, secure fit |

| Ladder and cleat backing structures | Reinforcement behind localized loads | Helps prevent pull-through and deck cracking |

5052 is a non-heat-treatable aluminum alloy strengthened primarily by cold work (temper). Its magnesium content is the heart of its marine corrosion performance, especially in splash zones and humid compartments.

Chemical Composition (Typical Limits)

| Element | Composition (%) |

|---|---|

| Magnesium (Mg) | 2.2–2.8 |

| Chromium (Cr) | 0.15–0.35 |

| Silicon (Si) | ≤ 0.25 |

| Iron (Fe) | ≤ 0.40 |

| Copper (Cu) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.10 |

| Zinc (Zn) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance |

Notes for marine buyers: low copper content supports corrosion resistance; magnesium improves seawater durability; chromium helps with strength and microstructural stability.

Temper Options for Marine aluminum angles

Choosing temper is choosing how the angle behaves during fabrication and service.

| Temper | Practical meaning | Typical deck use case |

|---|---|---|

| O (Annealed) | Softest, highest formability | Complex forming, tight fit-ups, prototypes |

| H32 | Strain hardened and stabilized | General-purpose marine framing and brackets |

| H34 | Slightly higher strength than H32 | Higher-load supports with minimal forming |

| H112 | As-fabricated (often extruded) | Structural angles where specs allow and formability is secondary |

Most custom boat deck projects favor 5052-H32 for its balance of strength, toughness, and fabrication friendliness.

Mechanical & Physical Properties (Typical)

Values vary with thickness, mill practice, and temper. These typical ranges are useful for early design and quoting.

| Property | Typical value for 5052-H32 |

|---|---|

| Ultimate tensile strength | 228–260 MPa |

| Yield strength (0.2%) | 165–200 MPa |

| Elongation | 8–15% |

| Hardness | ~60–70 HB |

| Density | 2.68 g/cm³ |

| Modulus of elasticity | ~70 GPa |

| Thermal conductivity | ~138 W/m·K |

| Melting range | ~607–649 °C |

Common Angle Dimensions & Supply Notes

Marine aluminum angles are commonly supplied as equal-leg or unequal-leg profiles, cut-to-length for fabrication shops. Availability depends on region and extrusion programs.

| Parameter | Common range (typical supply) |

|---|---|

| Leg length | 15–150 mm (equal or unequal) |

| Thickness | 2–12 mm |

| Standard length | 3–6 m (cut lengths available) |

| Corner radius | Extrusion radius varies; tighter radii often cost more |

| Tolerance focus | Straightness and twist matter for long deck edges |

Design tip: for long deck stiffeners, prioritize straightness and consistent leg thickness to reduce fit-up time and distortion during welding.

Fabrication Guidance for Boat Deck Builders

Cutting, drilling, and fitting

5052 angles machine cleanly with standard shop tooling. For repeatable deck builds, angle profiles help create consistent datum edges-a big advantage when assembling panels and hatches.

| Process | Recommendation | Benefit |

|---|---|---|

| Saw cutting | Carbide blade, avoid excessive heat | Cleaner edges, less oxide smearing |

| Drilling | Use sharp bits, moderate feed | Reduces burrs and elongation |

| Deburring | Light chamfer or radius | Helps coating adhesion and reduces crack starters |

| Notching | Leave smooth internal radii | Better fatigue resistance at corners |

Welding considerations

5052 is widely used in welded marine structures, but distortion control matters on decks where flatness is visible.

| Welding factor | Practical approach |

|---|---|

| Filler selection | Commonly 5356 for marine structural welds (project-dependent) |

| Heat input | Use controlled passes; avoid overwelding |

| Fixturing | Clamp for straightness; stitch and alternate sides |

| Post-weld cleanup | Remove soot/oxide; prep for coating or passivation steps |

Corrosion Behavior in Marine Deck Environments

5052 is recognized for strong performance in salt-laden air, splash zones, and wet interiors. Still, "marine-grade" does not mean "no maintenance."

| Marine risk | What to do with 5052 angles | Result |

|---|---|---|

| Galvanic corrosion (stainless fasteners, carbon steel contact) | Isolate with nylon washers, barrier tapes, coatings | Less pitting around joints |

| Crevice corrosion under trapped moisture | Seal seams, avoid water traps, allow drainage | Longer life in deck cavities |

| Abrasion exposing fresh metal | Use suitable coating or anodizing where aesthetics matter | Better appearance retention |

| Dissimilar metal contact | Use compatible fasteners and isolation strategies | Reduced long-term joint damage |

Finishing Options for Deck Hardware and Frames

| Finish | Best for | Notes |

|---|---|---|

| Mill finish | Hidden framing, under-deck supports | Most economical; expect cosmetic oxidation |

| Brushed/satin | Visible edges, interior trim | Better appearance; hides scratches |

| Anodized | Cosmetic and corrosion enhancement | Confirm alloy/temper compatibility with finish requirements |

| Marine paint system | High-visibility or color-matched parts | Prep quality determines coating life |

Specifying 5052 Marine aluminum angles for Your Project

For clean procurement and fewer surprises, it helps to define the angle by alloy, temper, and dimensional needs rather than "marine angle" alone.

| What to specify | Example |

|---|---|

| Alloy | AA 5052 |

| Temper | H32 (common) |

| Profile | Equal-leg or unequal-leg |

| Dimensions | Leg × leg × thickness (mm) |

| Length | Cut length or full mill length |

| Finish | Mill / brushed / anodized / paint-ready |

| Certification needs | Mill test report, chemistry and mechanicals if required |

5052 Marine aluminum angles are a lightweight, corrosion-resistant structural solution for custom boat deck engineering, used for framing, stiffening, hatch openings, console mounts, and reinforcement where saltwater durability matters. With excellent weldability, reliable strength in H32 temper, and versatile sizing, 5052 angles help builders create cleaner deck lines, stronger edges, and longer-lasting assemblies-without the weight and corrosion risks of steel.

5052 Marine aluminum angles for custom boat decks deliver excellent saltwater corrosion resistance, strong weldability, and dependable structural support for deck framing, hatch reinforcement, and mounting brackets. Available in common marine tempers like 5052-H32, these aluminum angles offer a lightweight, durable solution for long-lasting boat deck engineering in harsh marine environments.

Related Products

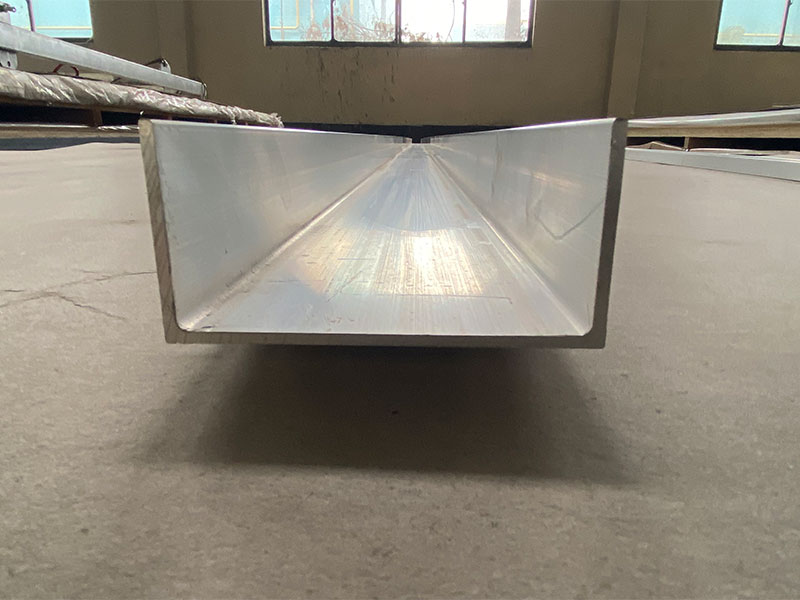

Marine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

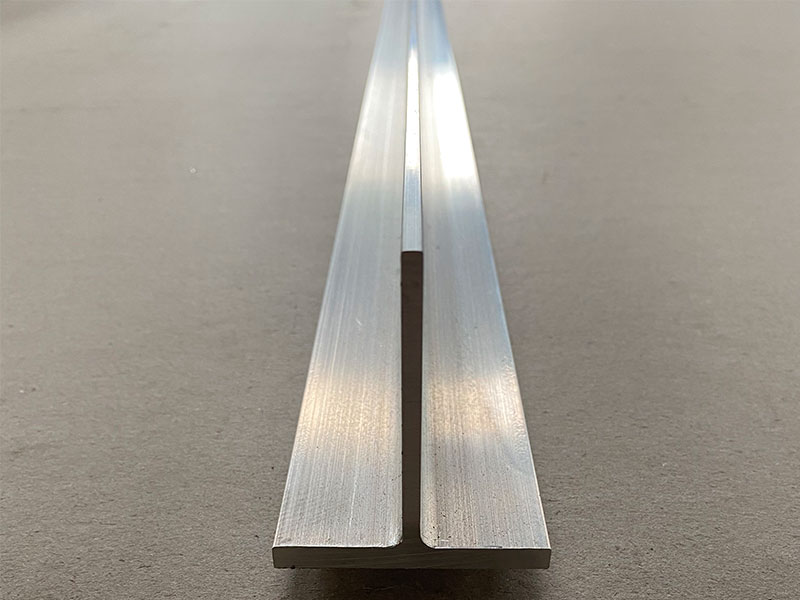

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsRelated Blog

5052 Marine Aluminum Z Shaped Sections for Lightweight Offshore Marine Construction

5052 Marine Aluminum Z Shaped Sections: A Structural Shortcut To Lightweight Offshore StrengthWhen naval architects and offshore engineers discuss weight savings, they usually start with plates, beams, and stiffeners.

View Details5052 Marine Aluminum Angles for Custom Coastal Engineering

In the dynamic field of coastal engineering, material selection plays an indispensable role in the longevity, reliability, and safety of offshore and shoreline structures.

View Details5052 Marine Aluminum Angles for Offshore Engineering and Shipbuilding

5052 marine aluminum angles are structural L-shaped extrusions (or brake-formed profiles) designed for saltwater exposure, cyclic loading, and weight-sensitive structures.

View Details5052 Marine Aluminum Angles for Custom Boat Deck Engineering

5052 marine aluminum angles are a go-to structural shape for boat deck builds where corrosion resistance, weldability, and dependable strength matter more than flashy specs.

View Details5052 Marine Aluminum Z Shaped Sections for Lightweight Offshore Ship Design

5052 marine aluminum Z shaped sections deliver high strength-to-weight performance, excellent corrosion resistance, and easy weldability for lightweight offshore ship design.

View Details5052 Marine Aluminum Z Shaped Sections for Heavy Duty Offshore Design

Marine aluminum plays a crucial role in the formation of innovative and dependable solutions within the maritime industry due to its lightweight and excellent resilience to corrosion.

View Details

Leave a Message