6061 marine aluminum round bar

6061 marine aluminum round bar is a versatile, corrosion-resistant, medium-to-high strength aluminum product widely used in marine hardware, offshore components, and coastal industrial equipment. While 5xxx-series alloys are often the first choice for fully immersed structures, 6061 (Al-Mg-Si) remains a favorite for machined parts, shafts, fittings, brackets, and structural details where a strong balance of strength, weldability, machinability, and availability is required.

For customers building in salt-air environments, marinas, boatyards, and offshore platforms, 6061 round bar delivers reliable mechanical performance, excellent fabrication flexibility, and predictable behavior in common surface treatments such as anodizing.

Why 6061 Works in Marine Environments

Marine service is rarely just "saltwater." It includes cyclic wetting/drying, splash zones, crevices, UV exposure, and dissimilar-metal contact. 6061 is valued because it forms a stable oxide layer and responds well to protective finishing. In practical use, it performs best when paired with good design practices such as drainage, isolation from copper-bearing alloys, and proper fastener selection.

features customers typically look for in 6061 marine round bar include:

- Balanced strength-to-weight for load-bearing parts without excessive mass

- Excellent machinability for tight-tolerance turned components

- Good weldability for brackets, frames, and assemblies (with appropriate filler selection)

- Strong corrosion performance in marine atmospheres, especially with anodizing or coating

- Availability in many diameters and tempers, supporting rapid procurement and prototyping

Typical Chemical Composition (6061)

The chemistry of 6061 is engineered around magnesium and silicon, which combine to form Mg₂Si-responsible for precipitation hardening and the alloy's well-known strength in T6/T651 tempers.

| Element | Typical Range (wt%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 0.80–1.20 |

| Silicon (Si) | 0.40–0.80 |

| Iron (Fe) | ≤0.70 |

| Copper (Cu) | 0.15–0.40 |

| Chromium (Cr) | 0.04–0.35 |

| Zinc (Zn) | ≤0.25 |

| Manganese (Mn) | ≤0.15 |

| Titanium (Ti) | ≤0.15 |

| Others (each) | ≤0.05 |

| Others (total) | ≤0.15 |

Note: Composition limits may vary slightly by standard and mill practice (ASTM/EN equivalents).

Mechanical Performance (Common Tempers)

For marine round bar, customers most often specify 6061-T6 (solution heat treated and artificially aged) or 6061-T651 (T6 plus stress-relief stretching for improved dimensional stability during machining).

| Property (Room Temp) | 6061-T6 / T651 Typical |

|---|---|

| Ultimate Tensile Strength | ~290–320 MPa |

| Yield Strength (0.2%) | ~240–280 MPa |

| Elongation (depending on diameter) | ~8–17% |

| Brinell Hardness | ~95 HB |

| Density | 2.70 g/cm³ |

| Modulus of Elasticity | ~69 GPa |

| Thermal Conductivity | ~167 W/m·K |

| Electrical Conductivity | ~40% IACS |

Values are representative; actual results depend on diameter, process route, and specification requirements.

Technical Specifications for Marine Round Bar (Practical Ordering Data)

6061 round bar is commonly stocked in extruded and drawn forms. Marine users typically focus on straightness, surface quality, and machinability rather than mirror finishes.

| Parameter | Common Options |

|---|---|

| Alloy | 6061 |

| Temper | T6, T651 (most common), also T4/T451 for forming needs |

| Form | Round bar (extruded, drawn) |

| Diameter range (typical stock) | ~6 mm to 300+ mm (availability varies by region) |

| Length | Fixed mill lengths or cut-to-length |

| Standards (common) | ASTM B221 (extruded), ASTM B211 (bar/rod), EN 755 / EN 754 equivalents |

| Dimensional tolerance | Standard mill tolerance or precision-drawn options |

| Surface condition | Mill finish; optional anodize-ready finishing |

| Certification | Mill test certificate, chemistry & mechanicals, heat/lot traceability |

Corrosion Behavior: What "Marine Grade" Means for 6061

6061 is not immune to corrosion, but it is highly serviceable in marine atmospheres when properly designed and finished. Its performance is shaped by exposure severity:

| Exposure Scenario | 6061 Performance | Practical Guidance |

|---|---|---|

| Salt-air / coastal atmosphere | Very good | Rinse cycles and anodizing boost life |

| Splash zone / intermittent wetting | Good | Avoid crevices; consider hardcoat or paint system |

| Continuous immersion | Fair to good | Prefer 5xxx for primary hull/plates; use 6061 for machined components with coatings |

| Galvanic contact with stainless/bronze | Risk increases | Use isolators, sealants, correct fasteners, and drainage |

| Crevice areas (under washers, clamps) | Risk increases | Seal interfaces; avoid trapped seawater |

Best practice in marine assemblies: if the round bar part contacts stainless fasteners or fittings, use non-absorbing isolating washers, a suitable barrier paste, and design for drainage and ventilation. This is often the difference between long service life and premature pitting.

Fabrication Advantages for Marine Hardware

Machining and dimensional stability

6061-T651 is frequently chosen for marine parts such as pins, rollers, bush housings, and precision spacers because stress relief helps reduce movement after heavy material removal. It turns cleanly and supports consistent surface finishes-valuable for sealing lands and bearing seats.

Welding and assembly

6061 welds well using common fillers (often 4043 or 5356 depending on service requirements). It is important to recognize that welding locally reduces strength in the heat-affected zone; many marine designs accommodate this by sizing weldments conservatively or by placing critical loads away from weld toes.

Surface treatments

6061 is widely anodized for marine service. Anodizing provides a hard, adherent oxide layer with improved corrosion resistance and wear performance, especially useful for parts exposed to abrasion, rope contact, or frequent handling.

| Surface Option | Marine Benefit | Typical Use |

|---|---|---|

| Clear anodize | Corrosion resistance, clean appearance | Rail fittings, brackets, deck hardware |

| Hardcoat anodize | High wear resistance | Sheaves, sliding parts, bush housings |

| Paint / epoxy systems | Barrier protection, color coding | Offshore frames, coastal equipment |

| Conversion coating | Paint adhesion, moderate protection | Under paint systems |

Typical Applications of 6061 marine aluminum round bar

6061 round bar is commonly selected for machined cylindrical parts and structural connectors where weight savings and corrosion control matter.

| Application Area | Example Parts Made from Round Bar | Why 6061 Fits |

|---|---|---|

| Boat & yacht hardware | Stanchion bases, cleat components, hinge pins, spacers | Good strength, machinability, anodize-friendly |

| Marine propulsion & steering | Couplings, linkages, shafts (light-duty), actuator parts | Stable machining, good fatigue behavior for moderate loads |

| Dock and marina systems | Roller pins, guide posts, brackets, adapters | Weathering resistance and easy fabrication |

| Offshore & coastal equipment | Sensor housings, clamps, frame connectors, lifting lugs (engineered) | Strength-to-weight and fast lead times |

| Aquaculture & workboats | Net system components, fastener blocks, bushing carriers | Corrosion control with coatings and isolation |

| General marine fabrication | Custom turned parts, prototyping, repair work | Readily available and shop-friendly |

Selection note: for highly stressed rotating shafts in corrosive wet service, engineering review is recommended to confirm fatigue margins, bearing fits, and protective finishing.

Selection Guidance: When to Choose 6061 vs Other Marine Alloys

| If your priority is… | Consider | Reason |

|---|---|---|

| High machinability + good strength | 6061-T651 | Excellent for turned parts and tight tolerances |

| Best corrosion resistance in seawater plate structures | 5083 / 5086 | Strong performers for hulls and welded platework |

| Higher strength with machining | 6082 (EU common) | Similar family; availability depends on region |

| Maximum strength | 7075 | Strong but generally less corrosion tolerant in marine exposure |

6061 excels as the "workhorse" alloy when the job includes machining, welding, and finishing, and when parts are exposed to salt air or splash rather than permanently submerged without protection.

What Customers Should Specify When Ordering

To get predictable performance in marine service, the purchase description should clearly identify parameters:

| Ordering Item | Recommended Detail |

|---|---|

| Alloy & temper | 6061-T6 or 6061-T651 (most marine machining) |

| Diameter & length | Nominal size, tolerance needs, cut-to-length |

| Straightness | Important for shafts and long turned parts |

| Certification | MTC with chemistry & mechanical properties |

| Surface expectation | Mill finish or anodize-ready; protective packaging if needed |

6061 marine aluminum round bar is a dependable choice for marine and coastal applications that demand lightweight strength, corrosion resistance, and machinability. It is especially well suited to precision-machined components, hardware, and structural connectors, and it integrates smoothly with common marine finishing systems such as anodizing and paint. With thoughtful design against galvanic and crevice corrosion, 6061 round bar provides long, cost-effective service across boats, docks, offshore equipment, and coastal industrial installations.

Related Products

6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

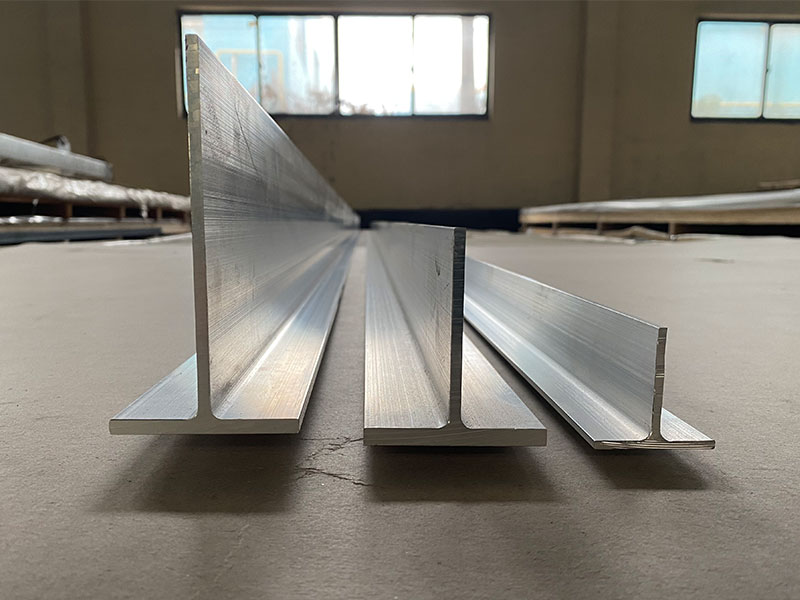

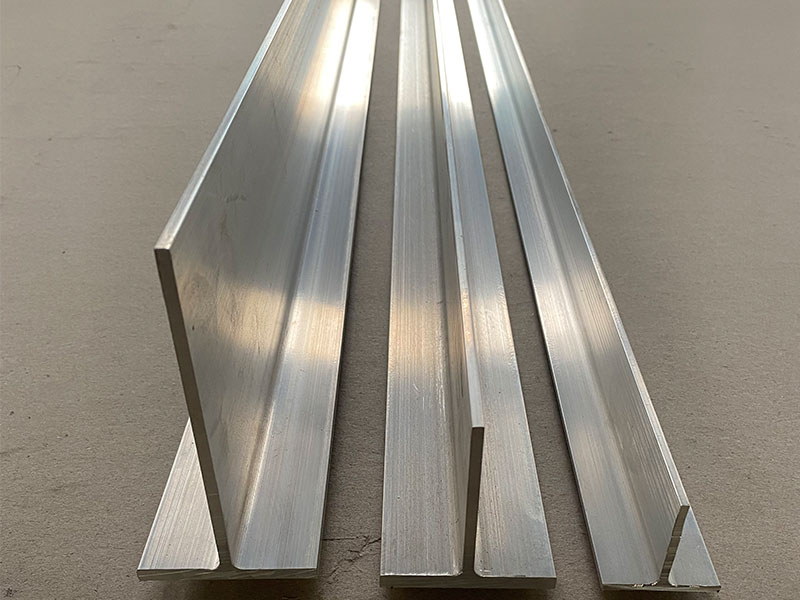

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsRelated Blog

6061 Marine Aluminum Angles for High Strength Coastal Marine Parts

6061 Marine Aluminum Angles are premium-grade structural aluminum components widely used in the marine industry due to their exceptional strength, corrosion resistance, and versatility.

View Details6061 T6 marine aluminum flat bar

6061 T6 marine aluminum flat bar is a widely used structural and fabrication material within the marine industry. Combining excellent strength, good corrosion resistance, weldability, and formability.

View Details6061 Marine Aluminum Round Bar for Custom Marine Vessel Parts

When it comes to marine vessel construction and maintenance, the materials chosen play an integral part in their functionality, longevity, and structural integrity.

View Details6061 Marine Aluminum Round Bar for Custom Marine Frame Fabrication

Marine environments are unforgiving — they demand resilience, lightweight strength, and excellent corrosion resistance from the materials we use in boat and frame fabrication.

View Details6061 Marine Aluminum Z Shaped Sections for Marine Frame Reinforcement

6061 Marine Aluminum Z Shaped Sections for Marine Frame ReinforcementMarine structures rarely fail because one component is "weak." They fail because loads travel through the hull in complicated paths, concentrate around cutouts and joints.

View Details6061 Marine Aluminum Round Bar for Seawater Resistant Boat Parts

When it comes to constructing durable, lightweight, and seawater resistant boat parts, 6061 Marine Aluminum Round Bar stands out as a top choice in the marine industry.

View Details

Leave a Message