Aluminum Sheet A5083 H116 H321 for Marine Ship

Aluminum Sheet A5083 in tempers H116 and H321 is a primary material choice for manufacturing marine vessels and shipbuilding components. It combines exceptional mechanical properties with strong corrosion resistance, particularly in harsh marine environments.

Alloy 5083 is part of the 5xxx series aluminum alloys, primarily alloyed with magnesium (Mg), providing excellent strength after cold working and outstanding corrosion resistance. It is non-heat-treatable but gains strength through strain hardening (work hardening).

Chemical Composition of Aluminum A5083 (Weight %)

| Element | Mg | Mn | Cr | Fe | Si | Zn | Cu | Al |

|---|---|---|---|---|---|---|---|---|

| Content | 4.0-4.9 | 0.4-1.0 | 0.05-0.25 | ≤0.4 | ≤0.4 | ≤0.25 | ≤0.1 | Balance |

Note: The exact composition may slightly vary depending on manufacturing standards but remains within these ranges.

Temper Designations: H116 vs. H321

H116: This temper is typically applied for aluminum used in marine environments to maintain resistance to exfoliation corrosion without compromising formability. It primarily reflects strain hardened with potentially some thermal treatments to improve corrosion behavior.

H321: The alloy is initially annealed and then strain-hardened and stabilized by a heat treatment that creates good mechanical strength while resisting stress corrosion cracking.

Mechanical Properties

| Property | A5083-H116 | A5083-H321 | Test Standard |

|---|---|---|---|

| Tensile Strength (MPa) | 275 - 350 | 250 - 330 | ASTM B209 / EN 485-2 |

| Yield Strength (MPa) | 145 - 215 | 150 - 270 | |

| Elongation (%) | ≥12 (depends on thickness) | ≥10 (depends on thickness) | |

| Hardness (Brinell HB) | 75 - 85 | 80 - 95 | |

| Density (g/cm³) | 2.66 | 2.66 |

Features of Aluminum Sheet A5083 H116 H321

1. Superior Corrosion Resistance

- Outstanding resistance to seawater, marine atmospheres, and industrial chemical environments.

- Resistant to exfoliation, pitting, and stress corrosion cracking—critical in aboard ship structures and hull plating.

2. Excellent Mechanical Strength

- High strength-to-weight ratio providing robust structural integrity without excessive weight increasing.

- Durable under mechanical loads while maintaining shock absorption capability essential for marine impact and vibrations.

3. Good Weldability and Fabrication

- Easily welded by MIG, TIG, and spot welding without loss of strength or corrosion resistance.

- Can accommodate bending, rolling, and other forming work due to acceptable ductility, especially in H116 temper.

4. Enhanced Fatigue Resistance

- Suitable for cyclic stress applications related to wave action and propulsion system vibrations.

Marine Applications of Aluminum A5083 H116 H321

- Ship Hull Plates:

- Due to excellent resistance to seawater corrosion and high impact energy absorption, A5083 sheets in these tempers are integral to aluminum marine hulls, maintaining structural integrity over extended service life.

- Superstructure and Decks:

- Lightweight and anti-corrosive for the decks and superstructures, ensuring reduced weight load to improve speed and fuel efficiency.

- Cargo Storage Tanks:

- Compatibility with chemicals and resistance to corrosive saltwater environments make it suitable for cargo tanks on marine vessels.

- Bulkheads and EPS Panels:

- Internal structural parts demanding rigidity and corrosion resistance benefit from A5083 sheet application.

- Other Shipbuilding Components:

- Winches, rails, bulkhead assemblies, and ramps, where high strength and corrosion resistance are mandatory.

Standards and Specifications

| Specification | Description |

|---|---|

| ASTM B209 | Aluminum and Aluminum-Alloy Sheet and Plate |

| EN 573-3, 485-2 | Aluminum and Aluminum Alloys Chemical Composition and Mechanical Properties |

| MIL-A-24779 | High strength corrosion resistant aluminum alloys |

Related Products

Marine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine 5083 aluminum sheet

Aluminum alloy 5083 is a non-heat-treatable alloy primarily composed of magnesium and trace elements that deliver outstanding protection against corrosion, particularly in seawater and saline atmospheres.

View DetailsMarine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine 5059 aluminum sheet

5059 aluminum alloy is a strain-hardened material with a unique addition of magnesium and chromium, which provides outstanding resistance to localized corrosion like pitting and stress corrosion cracking.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsRelated Blog

Aluminum Sheet A5083 H116 H321 for Marine Ship

Aluminum Sheet A5083 in tempers H116 and H321 is a primary material choice for manufacturing marine vessels and shipbuilding components. It combines exceptional mechanical properties with strong corrosion resistance.

View DetailsMarine aluminum 5083

In-depth insights into Marine Aluminum 5083, its chemical composition, mechanical properties, temper conditions, and why it stands as the premier alloy for marine and offshore structural applications.

View Details5052 5083 alloy 16 gauge aluminum sheet for boat building

5052 Aluminum Alloy5052 aluminum alloy is a non-heat treatable alloy known for its exceptional corrosion resistance, especially against saltwater, making it a popular choice for marine environments.

View Details5083 aluminium marine grade 3.2 mm thick aluminium sheet

5083 Aluminium Marine Grade 3.2 mm Thick Aluminium Sheet: Unveiling Its Functional Excellence and Versatile ApplicationsIn the realm of marine engineering, material selection determines durability, safety, and performance.

View DetailsAntiCorrosion 5083 Aluminum Sheet for Marine

Superior corrosion resistance and high strength of AntiCorrosion 5083 Aluminum Sheets, specifically designed for marine applications. Learn detailed specifications, alloy tempering, mechanical properties, and implementation standards in this comprehensive

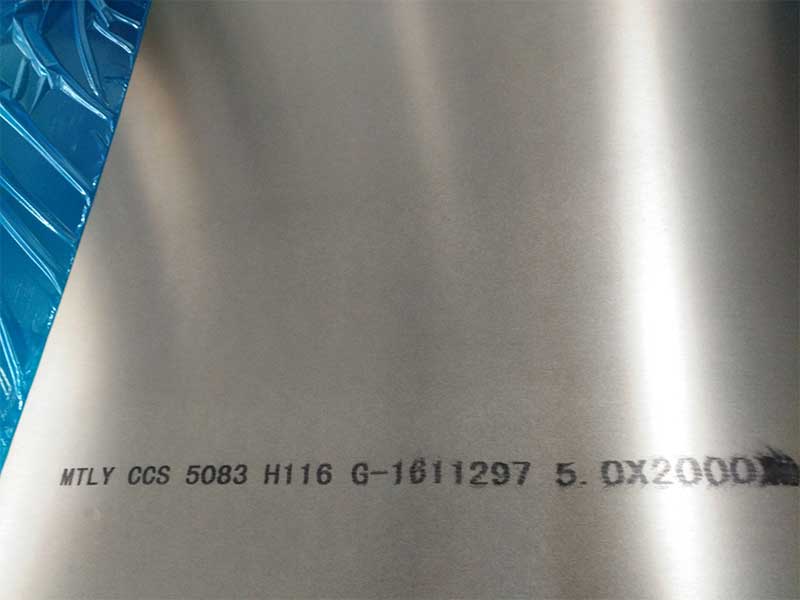

View DetailsAluminum sheet 5083 h116 with certificate of CCS for marine

High-performance Aluminum Sheet 5083 H116, certified by CCS for marine use. Explore its chemical properties, mechanical parameters, tempering conditions, and compliance standards making it ideal for marine environments.

View Details

Leave a Message