6063 Marine Aluminum Heat Sink Profile for Coastal Platform Electronics

6063 Marine Aluminum Heat Sink Profile for Coastal Platform Electronics

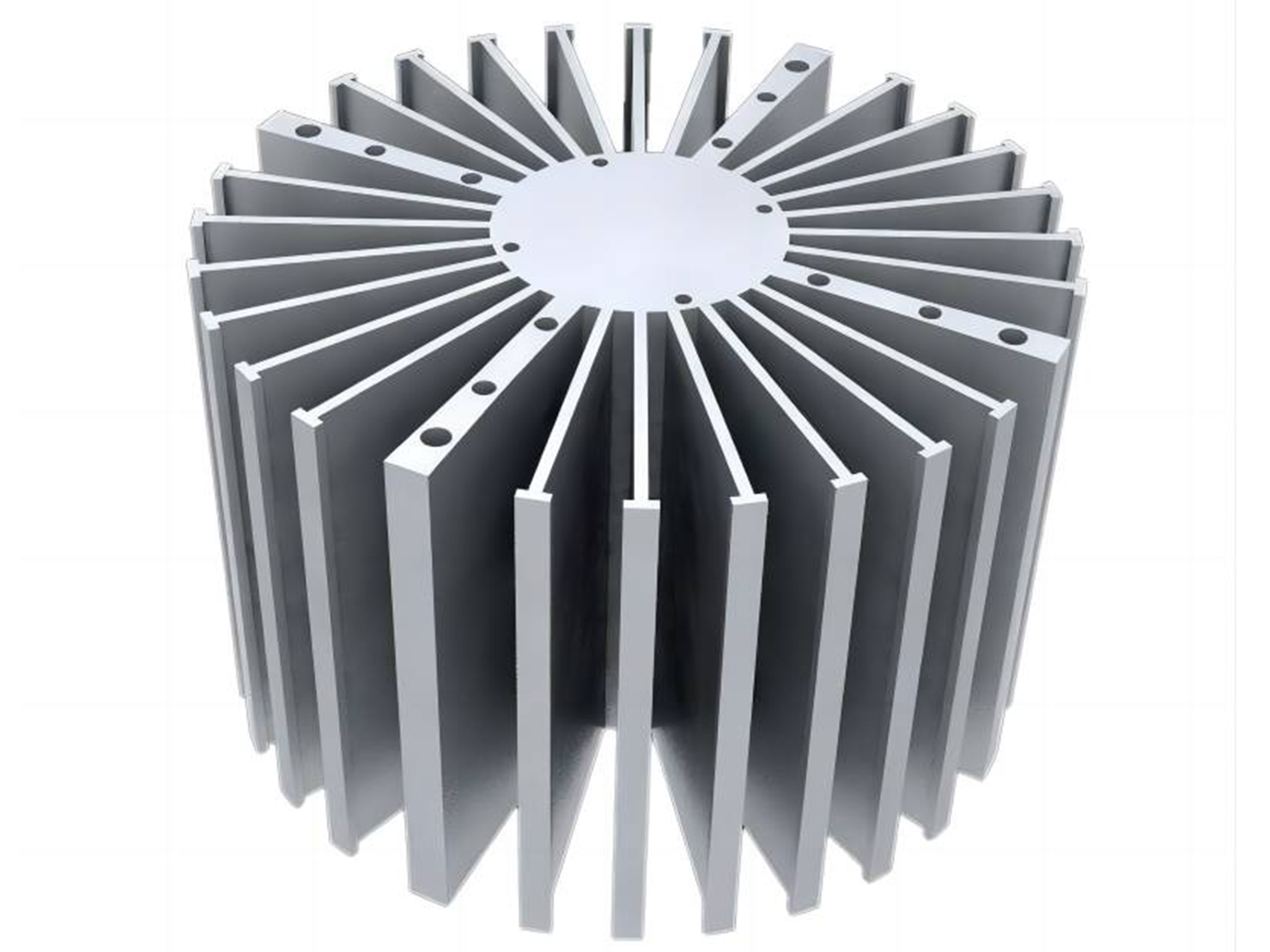

In coastal platform electronics—where environmental conditions are harsh and continuous operation is critical—effective thermal management is essential. Heat sinks are integral components to dissipate heat away from electronic devices, thus ensuring longevity and reliable performance. Among the materials available, 6063 marine aluminum heat sink profiles is know due to their unique combination of thermal conductivity, corrosion resistance, and structural integrity tailored for maritime applications.

Why 6063 Aluminum for Marine Heat Sinks?

6063 aluminum alloy is an extrusion-grade billet known primarily for its excellent strength-to-weight ratio, environmentally durable finish, and workability. Its use in marine contexts—especially electronic heat sinking—results from several distinct features:

- High Corrosion Resistance: Coastal environments involve persistent exposure to salt spray, humidity, and temperature fluctuations, which accelerate corrosion. The 6063 alloy forms a protective oxide layer that naturally resists these elements, impairing pitting and stress corrosion cracking even under extended marine use.

- Good Thermal Conductivity: While not as conductive as pure aluminum, 6063 offers effective thermal conduction sufficient to rapidly dissipate operating heat from electronic components mounted on coastal platforms: sensors, control units, communication devices, etc.

- Customizable Profiles: As the "architectural alloy," 6063 allows precise extrusion of complex multi-fin heat sink profiles. These profiles increase the surface area exposed to ambient airflow or liquid cooling, enhancing convection-based heat dissipation.

- Machinability and Finishable: 6063 marine aluminum profiles can be anodized or powder coated to amplify resistance and aesthetic appeal without adversely affecting performance.

Typical Applications on Coastal Platforms

6063 marine aluminum heat sinks are indispensable in safeguarding electronics on platforms such as:

- Weather and Environmental Monitoring Stations: Protect embedded sensing circuits.

- Navigation and Communication Equipment: Maintain optimum operating temperatures for radio modules and chipset processors exposed beachside or on marine buoys.

- Offshore Energy Platforms: Help electronic control systems maintain stable operations.

Product Features and Specifications

- Alloy: 6063-T6 Marine Grade

- Thermal Conductivity: Approximately 200 W/mK, ensuring efficient heat spread.

- Surface Treatment Options: Anodizing (Class II CC or higher for marine applications), powder coating.

- Profile Dimensions: Customizable extrusion lengths (typically standardized from 1000mm up to 6000mm) and complex fin designs for maximized surface area.

- Mechanical Properties: Yield strength ~ 160-220 MPa, tensile strength ~230-290 MPa, sufficient to resist mechanical stress due to platform vibrations and handling.

- Weight: Lightweight - easing installation and integration without compromising durability.

- Auxiliary Compatibility: Profiles can incorporate MCPCB mounting channels, fixing grooves, or cable conduits.

Advantages Over Alternative Materials

Many thermal management solutions on the market use copper or steel heat sinks. While copper offers superior thermal conductivity, its weight and susceptibility to chemical corrosion in marine environments limit its application. Steel, though stronger mechanically, is less thermally conductive and prone to rust without fishermen-like sacrificial coatings. In contrast, 6063 marine aluminum balances thermal performance and corrosion resistance relevant for coastal demands.

Sustainability Considerations

6063 marine aluminum sections are highly recyclable, promoting a circular economy approach. Use of marine-grade alloys like 6063 likewise contributes to safety and reduced maintenance/repair efforts—greatly supporting long-term operations planning and reducing down-times in remote maritime locations.

Related Products

Marine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsMarine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsRelated Blog

Marine Aluminum Fencing and Railings for Durable Boat Deck Guardrails

OverviewMarine aluminum fencing and railings are purpose-designed alloy systems used for guardrails, handrails, stanchions, and safety barriers on boats, docks, marinas, and waterfront properties.

View Details6063 Marine Aluminum Heat Sink Profile for Seawater Resistant Cooling Systems for Boats

When it comes to boats and marine systems, efficient heat dissipation combined with exceptional corrosion resistance is crucial for reliable operations.

View Details6063 Marine Aluminum Heat Sink Profile for Coastal Platform Electronics

Advantages of 6063 marine aluminum heat sink profiles, engineered to provide superior thermal management and corrosion resistance for coastal platform electronics. Ideal for harsh maritime environments.

View Details6063 Marine Aluminum Heat Sink Profile for Efficient Cooling of Offshore Equipment

In the marine and offshore industry, equipment reliability and performance hinge on effective thermal management solutions. Heat dissipation is a critical factor influencing the longevity and efficiency of sensitive offshore electronics and machinery.

View Details

Leave a Message