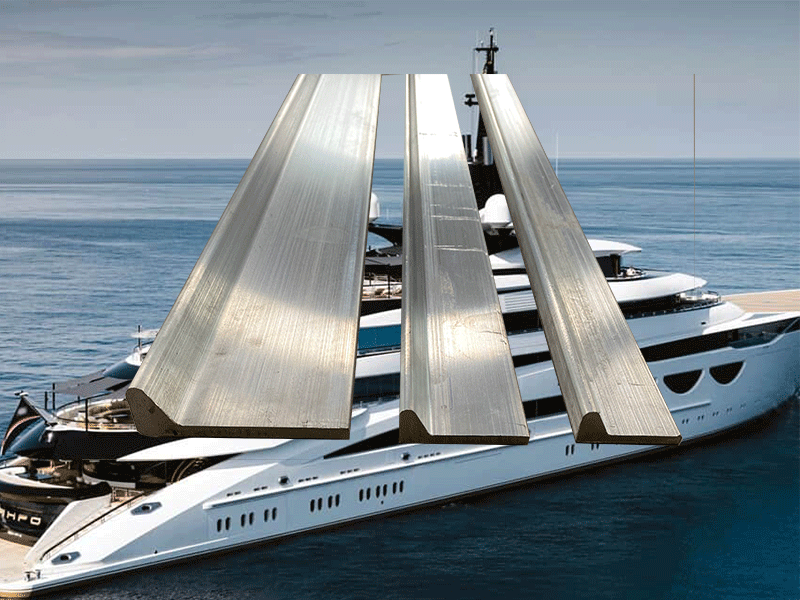

Customized Marine Aluminum Profiles for Interior and Exterior Ship Applications

Customized Marine Aluminum Profiles are precision-designed and fabricated aluminum alloy extrusions tailored to meet the unique demands of both interior and exterior shipboard applications. Leveraging the exceptional corrosion resistance, lightweight strength, and fabrication versatility of marine-grade aluminum alloys, these bespoke profiles enable shipbuilders and marine engineers to deliver high-performance, durable, and aesthetically pleasing solutions that withstand the severe conditions of the marine environment.

Customized Marine Aluminum Profiles are produced from top-tier aluminum alloys such as 5083, 5052, 6061, and 6082, each selected based on their proven ability to resist corrosion from seawater, salt spray, and marine atmospheres. Through advanced extrusion processes followed by precision fabrication, these profiles can be crafted into virtually any cross-sectional shape, ranging from structural beams and framing to decorative trims and facades.

The customization capability allows integration of multiple functions—such as reinforcement ribs, fastening grooves, cable management channels, and aesthetic features—into a single profile, streamlining installation and enhancing structural efficiency.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Marine-Grade Aluminum Alloys | High-performance alloys with superior seawater corrosion resistance | Long-lasting operation with minimal maintenance |

| Fully Customizable Designs | Profiles tailored to specific project requirements and constraints | Optimized fit, function, and fabrication flexibility |

| Lightweight and High Strength | Aluminum’s low density combined with alloy strength enables durable yet lightweight structures | Improved fuel efficiency and vessel performance |

| Enhanced Fabrication Properties | Easily welded, machined, bent, and finished to exacting standards | Simplifies complex assemblies and onsite modifications |

| Integrated Functional Elements | Profiles may include mounting slots, wiring channels, ventilation fins, and reinforcing ribs | Reduces part count and speeds installation |

| Aesthetic and Structural Versatility | Suitable for both visible interior décor elements and rugged exterior structural components | Meets both performance and design criteria |

Common Marine Aluminum Alloys Used

| Alloy | Key Attributes | Typical Applications |

|---|---|---|

| 5083 | High Mg content, outstanding corrosion resistance | Hull framing, bulkheads, structural sections |

| 5052 | Flexible formability and corrosion resistance | Interior panels, trim, cabinetry |

| 6061 | Heat-treatable alloy with good strength | Superstructure framing, door/window frames |

| 6082 | High strength with balanced corrosion resistance | High-load bearing parts and exterior fittings |

Manufacturing Process

Design Consultation and CAD Modeling: Custom profiles begin with precise engineering and 3D design to meet specific functional and aesthetic goals.

Extrusion: Hot aluminum billets are extruded through custom dies, producing profiles to exact cross-sections with uniform wall thickness and surface finishes.

Heat Treatment/Tempering: Applied as necessary (e.g., T6 temper) to achieve desired mechanical properties.

Secondary Fabrication: Includes cutting, drilling, bending, welding, anodizing, or powder coating tailored to marine standards.

Quality Control: Inspections and testing ensure dimensional accuracy, mechanical integrity, and corrosion resistance suitable for marine use.

Interior Applications

Wall and Ceiling Panels: Lightweight, corrosion-resistant panels with integration channels for wiring and fixtures.

Door and Window Frames: Durable frames with corrosion protection and thermal efficiency.

Cabinetry and Furniture: Custom-shaped trim and supports combining strength and refined appearance.

Handrails and Stair Components: Ergonomic, safe, and stylish profiles with durability in humid marine interiors.

Ventilation Grilles and Covers: Formed to optimize airflow while resisting corrosion and wear.

Exterior Applications

Hull Superstructure Framing: Structural beams and supports providing weight savings and corrosion protection.

Deck Edge Trims and Fascia: Protective, decorative elements resistant to salt spray and mechanical impact.

Railings and Guardrails: Robust safety barriers fabricated to marine standards with extended lifespan.

Access Covers and Hatches: Lightweight yet strong profiles ensuring secure tight seals against marine elements.

Signage and Lighting Fixtures: Durable profiles housing and protecting functional equipment against marine conditions.

Advantages Over Traditional Materials

| Aspect | Customized Marine Aluminum Profiles | Stainless Steel Components | Conventional Steel Profiles |

|---|---|---|---|

| Corrosion Resistance | Naturally resistant, enhanced with coatings | Excellent but heavier and costlier | Poor without protective treatments |

| Weight | Lightweight, reducing structural mass | Heavy and more limited in profile shapes | Heavy, increasing vessel weight |

| Fabrication Flexibility | Easily extruded into complex custom shapes | Limited to standard shapes, costly machining | Limited shaping without high cost |

| Maintenance | Minimal, inherently corrosion resistant | Moderate; potential for surface tarnish | High maintenance and frequent painting |

| Cost | Moderate; optimized for specific applications | High initial cost and fabrication time | Low initial cost; high life-cycle expense |

Maintenance and Care

Frequent rinsing with fresh water removes salt and marine contaminants.

Clean using mild detergents and non-abrasive cloths or brushes to preserve anodized or coated finishes.

Inspect welded joints, fastener interfaces, and exposed edges for mechanical damage or corrosion.

Regularly reapply protective coatings in severe environments to prolong lifespan.

Employ galvanic isolation techniques when joining aluminum profiles with dissimilar metals.

Customized Marine Aluminum Profiles provide shipbuilders and marine engineers with unparalleled design freedom and material performance to address unique challenges in vessel interior and exterior construction. Their corrosion resistance, combined with lightweight strength and fabrication adaptability, enables the creation of efficient, durable, and visually appealing marine structures and components.

For tailored profile solutions, advanced design support, and supply expertise, reach out to our marine metals professionals who are dedicated to advancing marine innovation with customized aluminum extrusions.

Related Products

Marine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsMarine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsRelated Blog

5052 Marine Aluminum Customized Shapes for Custom Marine Frame Solutions

5052 marine aluminum is a high-strength, corrosion-resistant alloy suitable for environments exposed to seawater and high humidity conditions. This alloy is particularly valuable for crafting customized marine frames, decking.

View DetailsMarine Aluminum Profiles

Marine aluminum profiles are a cornerstone of modern marine design and construction. Their unique chemical properties and tempering standards make them not only lightweight but also incredibly robust for a variety of marine applications.

View Details5083 Marine Aluminum Fencing and Railings for Durable Coastal Property Barriers

When a coastal property owner chooses fencing and railings, the conversation usually revolves around style, code compliance, and budget. The ocean, however, has its own priorities: salt, moisture, wind, and UV radiation.

View DetailsMarine Aluminum Customized Shapes for Marine Engineering Custom Fabrications

High-quality marine aluminum customized shapes tailored for marine engineering custom fabrications. Enhance durability, corrosion resistance, and structural integrity with precision-engineered aluminum solutions designed specifically for maritime applicat

View Details5052 Marine Aluminum Fencing and Railings for High Performance Coastal Guardrails

As we push the boundaries of engineering and architecture in coastal environments, 5052 marine aluminum fencing and railings is know as a notable solution. Functioning not only as an elegant aesthetic feature but also ensuring safety and durability.

View Details6061 Marine Aluminum Customized Shapes for Saltwater Resistant Shipbuilding Frames

Marine aluminum alloys play a critical role in shipbuilding, exhibiting remarkable resistance to corrosion, high strength-to-weight ratios, and ease of fabrication.

View Details

Leave a Message