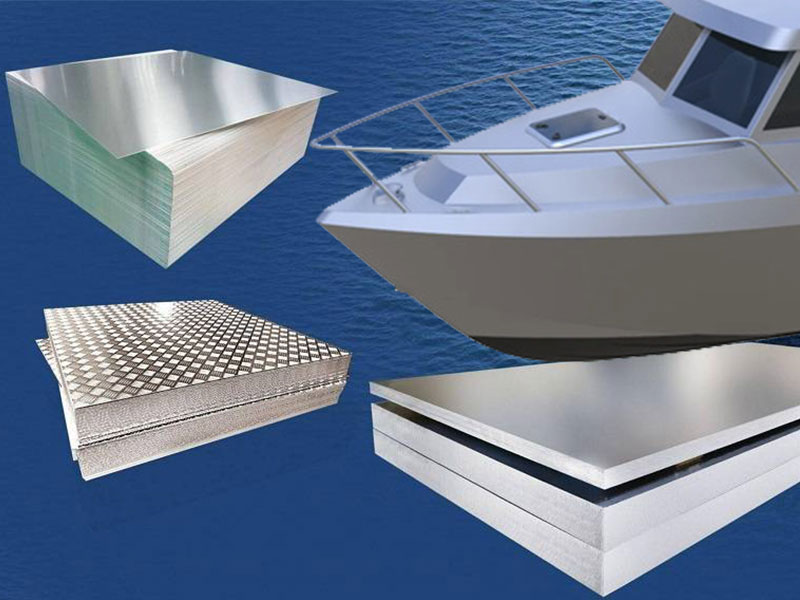

Marine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View Details

Marine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

- Alloy5052

- TemperF / O / H12 / H14 / H16 / H18 / H19 / H22 / H24 / H26 / H28 / H32 / H34 / H36 / H38 / H111 / H112 / H114

- Thickness0.15-600mm

Marine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

- Alloy5083,5052,6061

- TemperO / H12 / H14 / H16 / H18 / H19 / H22 / H24 / H26 / H28 / H32 / H34 / H36 / H38 / H111 / H112 / H114 / H116 / H321

- Thickness0.4-600mm

Marine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

- Alloy5052

- TemperF / O / H12 / H14 / H16 / H18 / H19 / H22 / H24 / H26 / H28 / H32 / H34 / H36 / H38 / H111 / H112 / H114

- Thickness0.15-600mm

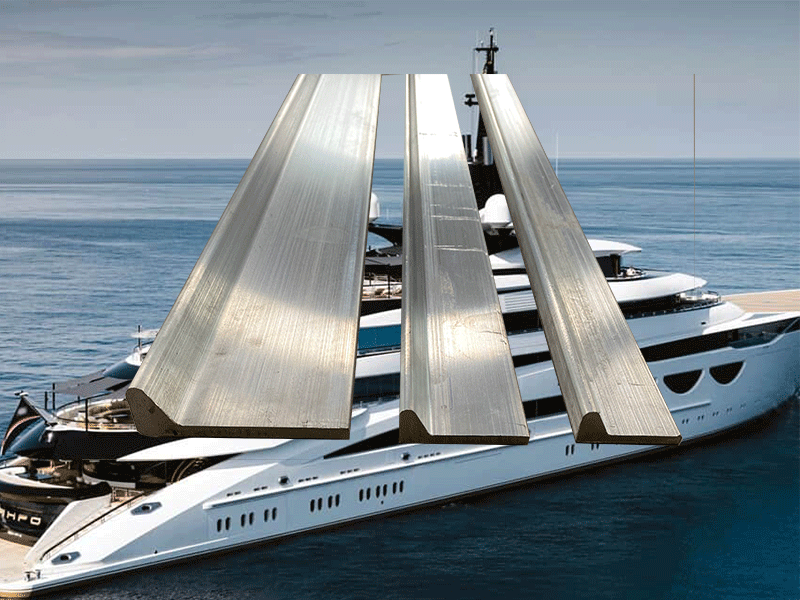

Marine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details

Marine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details

Marine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details

Marine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

- Alloy5083,5052,6061,6082

- TemperO / T4 / T6 / H12 / H14 / H16 / H18 / H19 / H22 / H24 / H26 / H28 / H32 / H34 / H36 / H38 / H111 / H112 / H114 / H116 / H321

- Thickness0.2-600mm

Marine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

- Alloy5083,5052,6061,6082

- TemperO / T4 / T6 / H12 / H14 / H16 / H18 / H19 / H22 / H24 / H26 / H28 / H32 / H34 / H36 / H38 / H111 / H112 / H114 / H116 / H321

- Thickness0.2-600mm

Marine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

- Alloy5083,5052,6061,6082

- TemperO / T4 / T6 / H12 / H14 / H16 / H18 / H19 / H22 / H24 / H26 / H28 / H32 / H34 / H36 / H38 / H111 / H112 / H114 / H116 / H321

- Thickness0.2-600mm

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

- Alloy5083,5052,6061,6082

- TemperO / T4 / T6 / H12 / H14 / H16 / H18 / H19 / H22 / H24 / H26 / H28 / H32 / H34 / H36 / H38 / H111 / H112 / H114 / H116 / H321

- Thickness0.2-600mm

Marine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

- Alloy5083,5052,6061,6082

- TemperO / T4 / T6 / H12 / H14 / H16 / H18 / H19 / H22 / H24 / H26 / H28 / H32 / H34 / H36 / H38 / H111 / H112 / H114 / H116 / H321

- Thickness0.2-600mm

Application

Marine Aluminum Tubing in Fluid Systems and Lightweight Structures

Marine aluminum tubing is an indispensable material in the maritime and offshore industries, prized for its exceptional corrosion resistance, lightweight nature, and mechanical versatility.

View Details

Structural and Fastening Applications of Marine Grade Aluminum Bars

Marine Grade Aluminum Bars are essential materials used extensively in the maritime and offshore industries for their outstanding combination of strength, corrosion resistance, and versatility.

View Details

Applications of Marine Aluminum Sheets in Shipbuilding and Superstructures

Marine aluminum sheets have become indispensable materials in modern shipbuilding and superstructure fabrication due to their unique combination of light weight, strength, corrosion resistance, and ease of fabrication.

View Details

Customized Marine Aluminum Profiles for Interior and Exterior Ship Applications

Customized Marine Aluminum Profiles are precision-designed and fabricated aluminum alloy extrusions tailored to meet the unique demands of both interior and exterior shipboard applications.

View DetailsBlog

Aluminum sheet for boat 5083 5052 5754

When selecting aluminum sheets for marine applications, particularly boats, alloy choice plays a vital role in ensuring durability, corrosion resistance, and mechanical strength.

View Details

5052 Marine Aluminum Channels for Custom Boat Frame Design

Marine aluminum is renowned for its corrosion resistance, lightweight properties, and strength, making it an ideal material for boat construction. Among the various series of aluminum alloys, the 5052 alloy stands out.

View Details

5052 h111 alloy aluminum marine plate

When it comes to marine aluminum plates, performance and reliability are non-negotiable qualities due to the challenging environments they encounter—saltwater corrosion, fluctuating temperatures, and mechanical stresses.

View Details

5052 Marine Aluminum Z Shaped Sections for Heavy Duty Offshore Design

Marine aluminum plays a crucial role in the formation of innovative and dependable solutions within the maritime industry due to its lightweight and excellent resilience to corrosion.

View Details

5052 Marine Aluminum Tubes for High Performance Boat Structures

When it comes to high-performance boat structures, the strength, weight, and durability of materials matter enormously. One of the most favored materials in the marine industry is **5052 Marine Aluminum Tubes.

View Details

Marine grade 5052 alloy aluminium sheet plate

Features — why choose 5052 for marine applicationsExcellent resistance to seawater and marine atmospheres (better than 3003, 6061 in chloride environments).Good fatigue strength and impact resistance for thin-gauge structural components.

View Details

5052 Marine Aluminum Hollow Bars for Saltwater Proof Marine Frames

When it comes to the maritime industry, choosing the right materials for constructing robust marine frames is imperative. Among various alloys, 5052 marine aluminum hollow bars have made a significant mark due to their superior properties.

View Details

5052 Marine Aluminum Customized Shapes for High Strength Offshore Platforms

Superior qualities of 5052 Marine Aluminum, a high-strength material ideal for customized shapes used in offshore platforms. Learn about its key features, applications, and technical specifications.

View Details

Aluminium sheet 8mm alloy 5052 h112 for boat

When selecting materials for marine applications, especially in boat building, the balance between strength, corrosion resistance, and workability is crucial. Aluminium sheet 8mm thick made from alloy 5052 in temper H112 epitomizes this balance.

View Details

5052 Marine Aluminum Angles for Heavy Duty Marine Applications

In the world of marine applications, the choice of materials can significantly influence performance and longevity. For heavy-duty usage, marine aluminum angles, particularly 5052 Marine Aluminum angles, come out as premier contenders.

View Details

Marine Aluminum Fencing and Railings for Durable Boat Deck Guardrails

OverviewMarine aluminum fencing and railings are purpose-designed alloy systems used for guardrails, handrails, stanchions, and safety barriers on boats, docks, marinas, and waterfront properties.

View Details

Marine Aluminum Alloy Plate 5052 5083 6061

Marine environments pose extreme challenges—constant exposure to saltwater corrosion, mechanical stresses, and environmental fluctuations demand materials that combine strength, durability, and corrosion resistance.

View Details