5052 Marine Aluminum Angles for Offshore Engineering and Shipbuilding

5052 Marine aluminum angles are structural L-shaped extrusions (or brake-formed profiles) designed for saltwater exposure, cyclic loading, and weight-sensitive structures. Built on Al-Mg alloy metallurgy, 5052 offers an excellent balance of corrosion resistance, formability, and weldability, making it a dependable choice for offshore engineering, shipbuilding, and coastal infrastructure where long service life and low maintenance matter.

Why 5052 for Marine Angles?

Marine structures fail most often at joints, edges, and crevice zones-exactly where angles are used. 5052 aluminum angles help reduce risk in these areas by combining:

- Strong seawater corrosion resistance (Al-Mg family): magnesium improves resistance in marine atmospheres and splash zones.

- High weld integrity: stable performance in MIG/TIG welded frames, brackets, and stiffeners.

- Excellent formability: tight radii and fabrication-friendly bends without brittle cracking.

- Weight savings: lower density than steel supports lighter hull modules and offshore topsides.

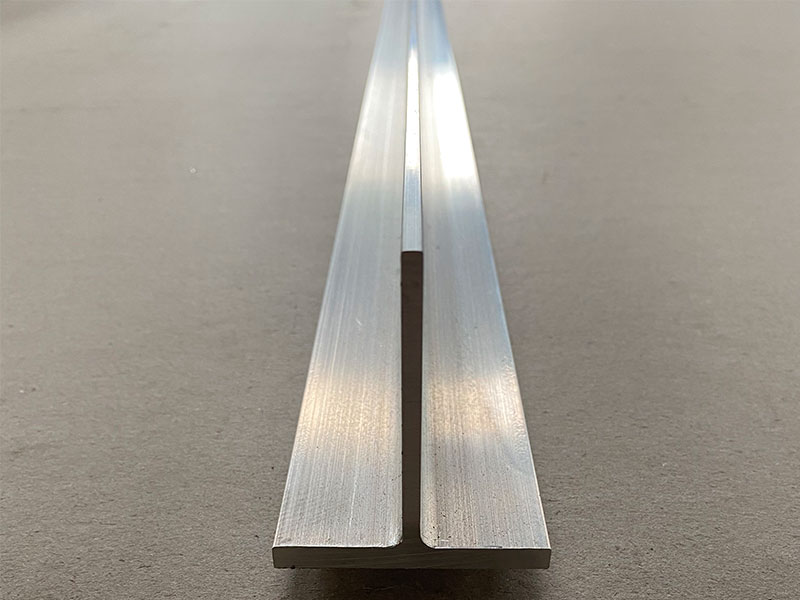

A 5052 aluminum angle is an L-profile used to reinforce corners, create stiffeners, mount equipment, and form frameworks. In offshore and shipbuilding, it is commonly used for:

- deckhouse framing and supports

- hatch coamings and edge reinforcement

- walkways, ladders, handrail brackets

- equipment skids and base frames

- brackets for cable trays and pipe supports

- interior modules where durability and low weight are required

Features and Benefits (Customer Value)

| Feature | What It Means in Real Use | Customer Benefit |

|---|---|---|

| Marine-grade corrosion resistance | Resists salt spray and marine atmosphere attack | Longer service life, fewer replacements |

| Good strength-to-weight | Strong enough for brackets and stiffeners without heavy steel | Reduced fuel/energy use, easier handling |

| Excellent weldability | MIG/TIG welding produces reliable joints | Faster fabrication, dependable assemblies |

| High formability | Bends, drills, and machines with low cracking risk | Easier customization and lower scrap |

| Non-magnetic & spark-resistant (relative) | Useful near sensitive equipment and hazardous areas | Safer, more compatible installations |

| Clean finish options | Mill finish, anodized, or painted systems | Better aesthetics and coating durability |

Chemical Composition (Typical, AA 5052)

5052 is an Al-Mg alloy with controlled minor elements to stabilize properties and processing.

| Element | Typical Range (wt.%) |

|---|---|

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Silicon (Si) | ≤ 0.25 |

| Iron (Fe) | ≤ 0.40 |

| Copper (Cu) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.10 |

| Zinc (Zn) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.10 |

| Aluminum (Al) | Balance |

Note: Limits can vary slightly by standard (ASTM/EN). Mill test certificates (MTC) confirm actual heats.

Mechanical Properties (Typical Values)

5052 is a non-heat-treatable alloy; its strength is achieved primarily through work hardening (temper). For marine angles, common tempers include H32 (popular balance of strength and formability) and H34/H112 depending on forming and weld plans.

| Property | 5052-H32 (Typical) | 5052-O (Annealed, Typical) |

|---|---|---|

| Tensile Strength (MPa) | 210 – 260 | 170 – 215 |

| Yield Strength, 0.2% (MPa) | 130 – 200 | 65 – 100 |

| Elongation (%) | 8 – 15 | 18 – 25 |

| Hardness (HB) | ~60 – 75 | ~45 – 55 |

| Density (g/cm³) | 2.68 | 2.68 |

Welding note: as with most work-hardened aluminum, the heat-affected zone (HAZ) will soften locally. Designs should account for this with joint geometry, reinforcement, or temper selection.

Technical Specifications (Angles for Offshore and Ship Use)

We supply 5052 angles in a range of sizes and production routes. The choice depends on load path, finish requirements, and tolerance expectations.

| Parameter | Typical Offering |

|---|---|

| Product form | Equal-leg and unequal-leg aluminum angles |

| Manufacturing | Extruded angle; also brake-formed from 5052 plate/sheet for special dimensions |

| Temper options | O, H32, H34, H112 (availability depends on size) |

| Leg length (A × B) | ~20–200 mm (custom ranges available) |

| Thickness (t) | ~2–12 mm (heavier by request) |

| Length | 3 m / 6 m standard; cut-to-length available |

| Tolerances | Per ASTM/EN extrusion tolerances or agreed project specs |

| Surface finish | Mill finish; anodizing-ready; paint-ready (with proper pretreatment) |

| Standards (common references) | ASTM B221 (extrusions), ASTM B928 (marine sheet/plate reference), EN 573 / EN 755 (EU equivalents) |

| Traceability | Heat number + Mill Test Certificate (MTC) |

Marine Performance: What to Expect Offshore

1) Corrosion Resistance in Saltwater Service

5052 performs well in marine atmospheres and splash zones due to its magnesium content and stable oxide film. It is widely chosen for coastal structures, deck equipment, and superstructure components where corrosion is a dominant failure mode.

Best practices to maximize corrosion life:

| Risk Area | Recommended Practice |

|---|---|

| Crevices & trapped moisture | Seal joints, avoid tight gaps, design for drainage |

| Galvanic corrosion | Isolate from carbon steel/copper alloys using gaskets, coatings, or insulating washers |

| Fastener compatibility | Prefer 316 stainless or coated fasteners with isolation where needed |

| Coating adhesion | Use proper cleaning + conversion coating/primer prior to paint |

2) Weldability and Fabrication

5052 is friendly to workshop fabrication: it cuts cleanly, drills predictably, and welds reliably. For welded offshore frames, 5356 filler is commonly used to maintain corrosion resistance and strength matching in many marine environments.

| Process | Typical Guidance |

|---|---|

| MIG/TIG welding | Excellent; use clean prep and correct filler |

| Bending/forming | Very good in O and H32; respect minimum bend radius for thicker sections |

| Machining | Good with sharp tooling and chip control |

| Heat treatment | Not heat-treatable for strengthening (strength comes from temper) |

Typical Applications in Offshore Engineering and Shipbuilding

| Segment | Use Case | Why 5052 Angle Fits |

|---|---|---|

| Shipbuilding | Deckhouse framing, stiffeners, hatch edge reinforcement | Corrosion resistance + lightweight structure |

| Offshore platforms | Cable tray supports, small structural brackets, equipment frames | Low maintenance in marine exposure |

| Coastal infrastructure | Walkways, railing reinforcement, dock components | Resists marine atmosphere attack |

| Marine equipment | Mounting frames, pump skids, sensor brackets | Weldable and easy to customize |

| Interior ship modules | Partitions, supports, HVAC frames | Good formability and clean finishes |

Selection Guidance: Getting the Right Angle for the Job

| Project Need | Recommended Choice |

|---|---|

| Maximum formability for complex bends | 5052-O or 5052-H32 (depending on thickness) |

| Higher stiffness/strength with moderate forming | 5052-H32 / H34 |

| Welding-heavy fabrication | Prefer H32 and design for HAZ softening |

| Painted marine structure | Specify surface prep requirements and coating system early |

| Tight tolerance assemblies | Discuss extrusion tolerances and straightness upfront |

5052 Marine aluminum angles deliver a proven blend of saltwater corrosion resistance, weldable fabrication, and weight efficiency that aligns with real offshore and shipyard demands. Whether used as edge reinforcement, stiffeners, brackets, or frame members, 5052 angles help reduce maintenance burden, simplify fabrication, and support long service life in harsh marine environments.

Related Products

Marine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsRelated Blog

5052 Marine Aluminum Angles for Heavy Duty Marine Applications

In the world of marine applications, the choice of materials can significantly influence performance and longevity. For heavy-duty usage, marine aluminum angles, particularly 5052 Marine Aluminum angles, come out as premier contenders.

View Details5052 Marine Aluminum Angles for Durable Marine Frame Solutions

5052 Marine Aluminum Angles for Durable Marine Frame SolutionsA technical, application‑driven perspective5052 marine aluminum angles are a backbone material in modern shipbuilding and offshore structures—quietly underpinning decks, bulkheads, ra.

View Details5052 Marine Aluminum Z Shaped Sections for Heavy Duty Offshore Design

Marine aluminum plays a crucial role in the formation of innovative and dependable solutions within the maritime industry due to its lightweight and excellent resilience to corrosion.

View Details5052 Marine Aluminum Channels for Custom Boat Hull Construction

Aluminum channels are indispensable components in marine construction, providing structural support, corrosion resistance, and design versatility. Among various aluminum alloys available.

View Details5052 Marine Aluminum Z Shaped Sections for Lightweight Offshore Ship Design

5052 marine aluminum Z shaped sections deliver high strength-to-weight performance, excellent corrosion resistance, and easy weldability for lightweight offshore ship design.

View Details5052 Marine Aluminum Angles for Offshore Engineering and Shipbuilding

5052 marine aluminum angles are structural L-shaped extrusions (or brake-formed profiles) designed for saltwater exposure, cyclic loading, and weight-sensitive structures.

View Details

Leave a Message