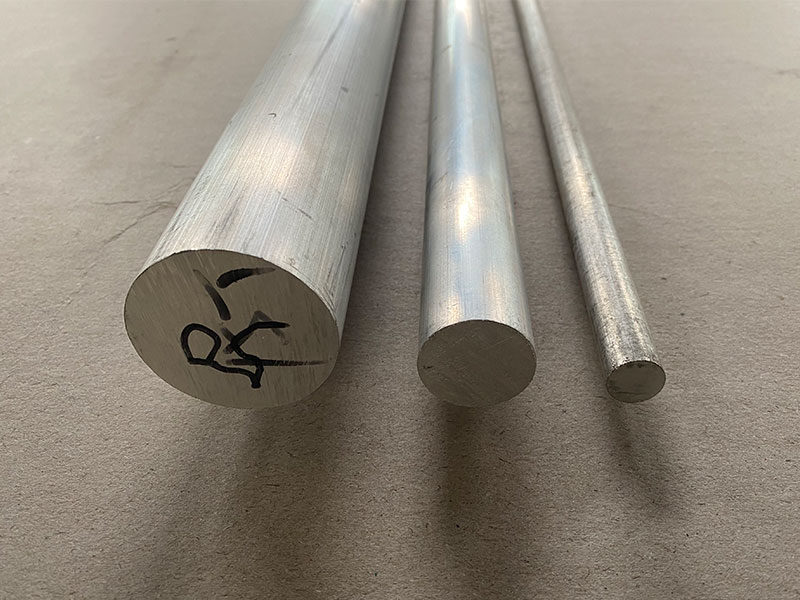

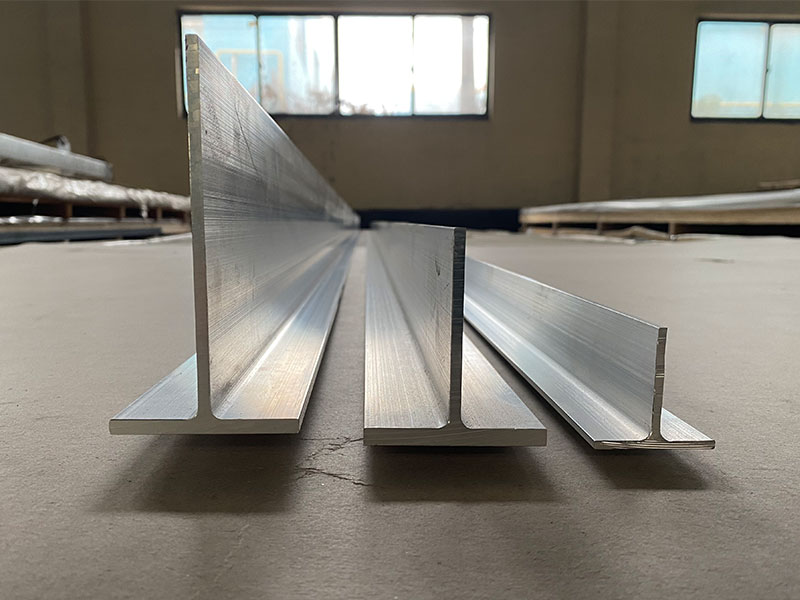

6061 Marine Aluminum Round Bar is a high-quality, versatile aluminum alloy product widely used in marine, offshore, and coastal applications. Recognized for its excellent strength-to-weight ratio, corrosion resistance, and excellent machinability, this alloy is specially suited for the harsh conditions of the marine environment. Fabricators, shipbuilders, and marine engineers rely on 6061 marine aluminum round bars for components that require durability, precision, and long-lasting performance in saltwater and corrosive atmospheres.

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance. The marine-grade 6061 T6 round bars are especially valued for their toughness, resistance to seawater corrosion, and good weldability, making them ideal for both structural and functional marine components.

Produced using precision extrusion or forging followed by finishing processes, 6061 marine aluminum round bars come in various diameters and lengths to suit fabrication and machining requirements.

Chemical Composition

The chemistry of 6061 alloy ensures a balanced performance of strength, corrosion resistance, and machinability:

| Element | Typical Range (%) |

|---|---|

| Silicon (Si) | 0.4 – 0.8 |

| Iron (Fe) | ≤ 0.7 |

| Copper (Cu) | 0.15 – 0.4 |

| Manganese (Mn) | ≤ 0.15 |

| Magnesium (Mg) | 0.8 – 1.2 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance |

Mechanical Properties

6061 T6 Marine Aluminum Round Bar delivers robust mechanical properties tailored for demanding marine environments:

| Property | Typical Value |

|---|---|

| Tensile Strength (MPa) | 310 – 350 |

| Yield Strength (MPa) | 270 – 300 |

| Elongation (%) | 8 – 12 |

| Brinell Hardness (HB) | 95 – 115 |

| Density (g/cm³) | 2.70 |

Physical and Thermal Properties

Density: Approximately 2.70 g/cm³, lighter than steel by nearly three times, providing weight savings in marine structures.

Thermal Conductivity: 167 W/m·K, facilitating rapid heat dissipation in machinery and equipment parts.

Melting Range: 580–650 °C, enabling thermal stability in fabrication and operational environments.

Electrical Conductivity: About 40% IACS, suitable for grounding or electrical components on vessels.

Manufacturing Process

6061 Marine Aluminum Round Bars are typically produced through the following steps:

Extrusion or Forging: Raw alloy billets are heated and shaped into round bar profiles with tight tolerances.

Heat Treatment: Solution heat-treated and artificially aged to achieve the T6 temper mechanical characteristics.

Surface Finishing: Supplied with mill finish; optional anodizing or protective coating available for enhanced corrosion defense.

Cutting and Machining: Can be cut to length and machined with high precision for structural or custom marine applications.

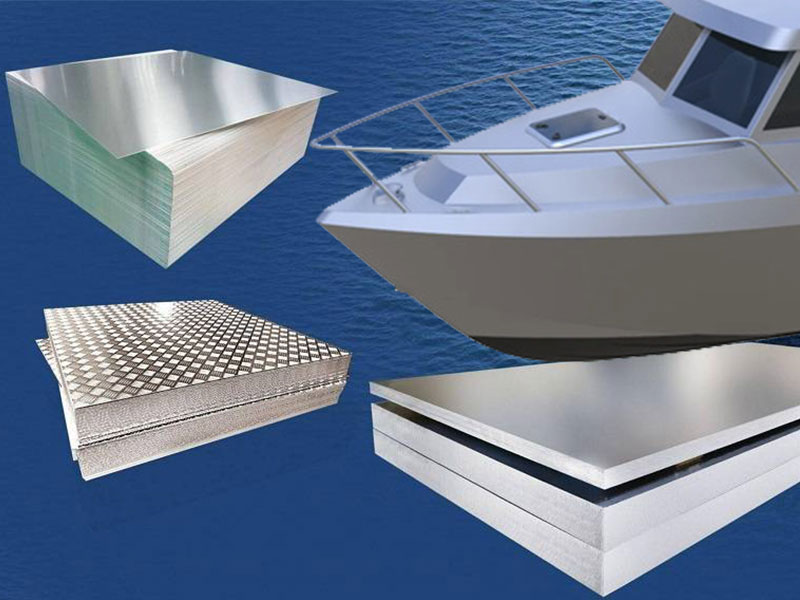

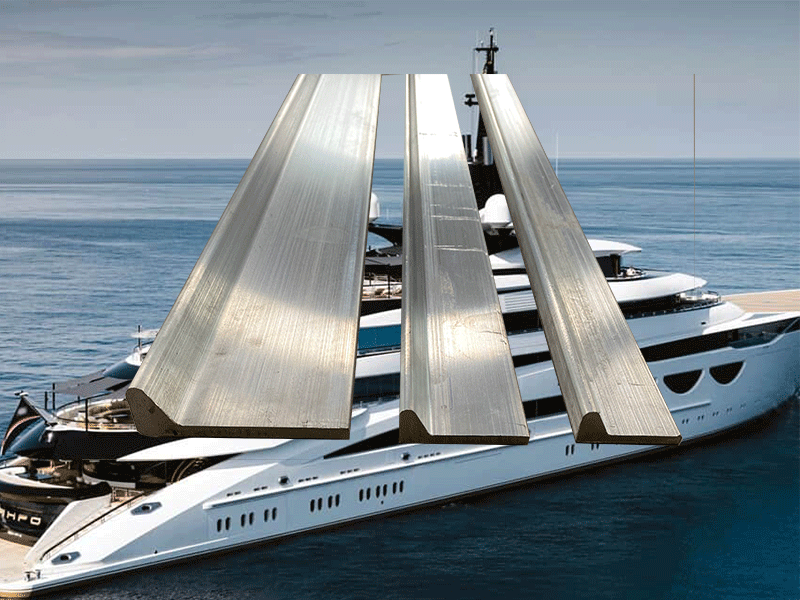

Typical Marine Applications

6061 T6 Marine Aluminum Round Bars are widely utilized for:

Shafts, axles, and spindles in marine propulsion and steering systems

Structural reinforcements and framing in shipbuilding and offshore platforms

Connectors, fittings, and mounting pins exposed to saltwater environments

Hydraulic and pneumatic cylinder rods used in marine machinery

Masts, rigging components, and lightweight marine hardware

Marine equipment enclosures, instrument housings, and custom fabricated parts

Advantages of 6061 Marine Aluminum Round Bar

High Strength and Toughness: Suitable for structural load-bearing parts requiring durability.

Excellent Corrosion Resistance: Performs well in seawater environments, preventing pitting and degradation.

Good Weldability: Compatible with TIG, MIG, and arc welding in marine fabrication.

Superior Machinability: Easily cut, drilled, turned, and threaded for precision parts.

Lightweight: Helps reduce overall vessel or offshore structure mass, enhancing efficiency.

Versatility: Wide availability of diameters and lengths to accommodate diverse marine designs.

Maintenance and Care

To maximize service life and maintain the properties of 6061 T6 Marine Aluminum Round Bars:

Regular Cleaning: Wash with fresh water to remove salt residues and marine contaminants.

Avoid Abrasive Materials: Use mild detergents and soft brushes to preserve surface integrity.

Inspection: Periodically check for physical damage, corrosion, or wear, especially near welds or mechanical contact points.

Protective Coating: Consider anodizing or marine-grade paint in highly corrosive environments for added protection.

Proper Storage: Store in dry, ventilated areas away from corrosive chemicals and direct salt exposure when not in use.

6061 T6 Marine Aluminum Round Bar offers a robust, corrosion-resistant, and machinable solution for marine industries requiring durable structural and mechanical components. Combining high strength and excellent corrosion resistance with lightweight properties, these round bars ensure reliability and long service life in challenging marine environments.

For detailed product specifications, custom sizing, or technical assistance, please contact our knowledgeable sales and engineering team for tailored guidance to meet your marine application needs.