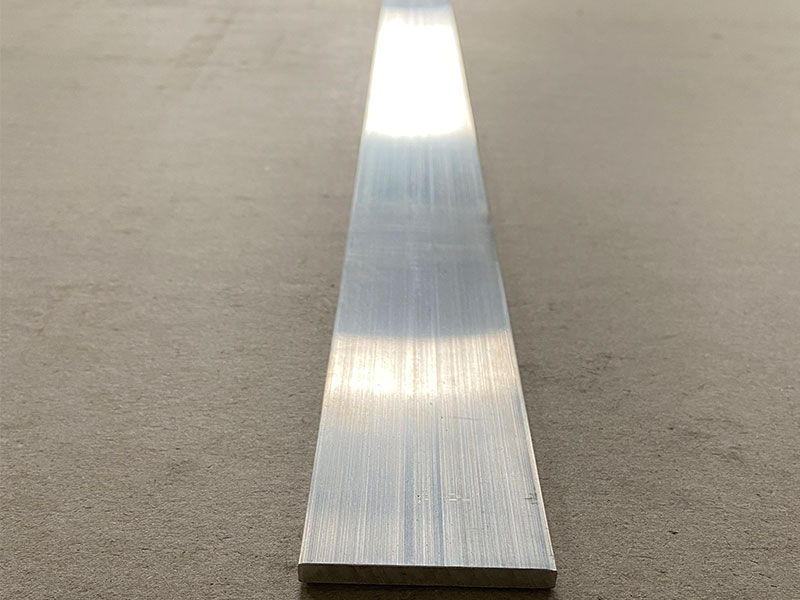

6061 T6 Marine Aluminum Flat Bar is a high-strength, corrosion-resistant aluminum alloy widely used in marine, offshore, and coastal applications demanding durability, lightweight construction, and excellent workability. Engineered to withstand the challenging saltwater environment, this alloy combines superior mechanical properties with good weldability and resistance to corrosion, making it an ideal material for marine fabricators, shipbuilders, and engineers.

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness. The combination of 6061 alloy chemistry and T6 tempering ensures excellent structural performance along with robust corrosion resistance in marine environments.

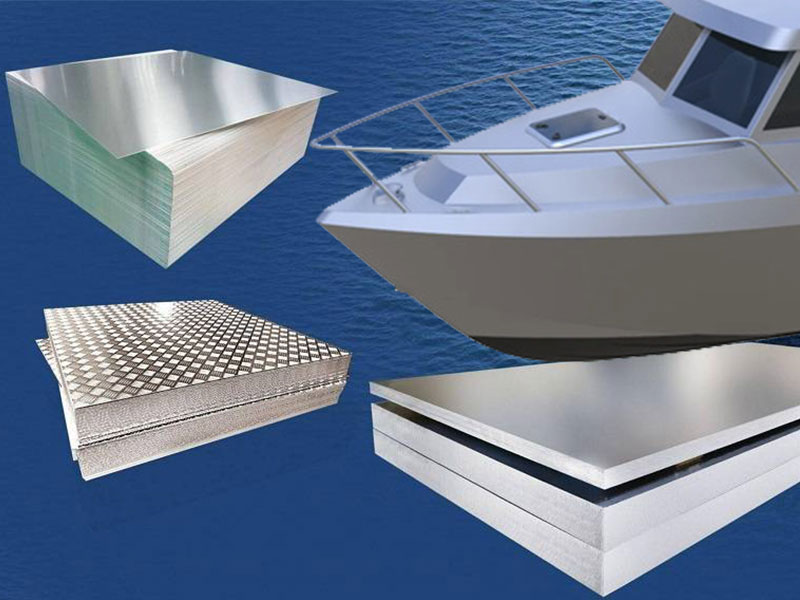

The Marine grade 6061 T6 flat bar is widely used for structural, framing, and support components where precision, toughness, and longevity are critical. Its intrinsic resistance to seawater corrosion makes it preferable for applications exposed directly or indirectly to salt spray and seawater.

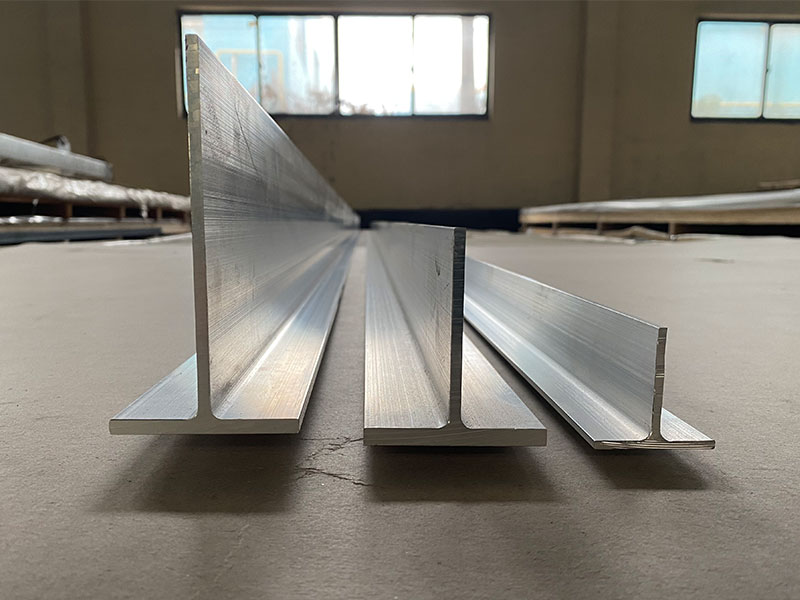

Manufactured through controlled extrusion or rolling processes with strict dimensional controls, 6061 T6 Marine Aluminum Flat Bars come in a variety of sizes and thicknesses to meet diverse marine construction and repair requirements.

Chemical Composition

The chemical composition of 6061 alloy used for marine flat bars is precisely formulated to balance strength and corrosion resistance:

| Element | Typical Range (%) |

|---|---|

| Silicon (Si) | 0.4 – 0.8 |

| Iron (Fe) | ≤ 0.7 |

| Copper (Cu) | 0.15 – 0.4 |

| Manganese (Mn) | ≤ 0.15 |

| Magnesium (Mg) | 0.8 – 1.2 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance |

Mechanical Properties

6061 T6 Marine Aluminum Flat Bar exhibits a high level of mechanical performance suited for load-bearing marine components:

| Property | Typical Value |

|---|---|

| Tensile Strength (MPa) | 310 – 350 |

| Yield Strength (MPa) | 270 – 300 |

| Elongation (%) | 8 – 12 |

| Brinell Hardness (HB) | 95 – 115 |

| Density (g/cm³) | 2.70 |

Physical Properties

Density: Approximately 2.70 g/cm³, making it significantly lighter than steel, which reduces weight on vessels and offshore structures.

Thermal Conductivity: About 167 W/m·K, enabling efficient heat dissipation.

Melting Range: 580 – 650 °C, stable under typical marine thermal cycles.

Electrical Conductivity: Roughly 40% IACS, useful for conductive and grounding applications.

Manufacturing Process

6061 T6 Marine Aluminum Flat Bars are manufactured typically by hot extrusion or rolling, followed by:

Solution Heat Treatment: To dissolve alloying elements.

Quenching: Rapid cooling to retain elements in a supersaturated solid solution.

Artificial Aging: Controlled heat treatment to precipitate strengthening phases achieving the T6 temper.

Cutting and Finishing: Flat bars are cut to size and can be finished with mill, anodized, or painted surfaces depending on marine specifications.

Typical Marine Applications

6061 T6 Marine Aluminum Flat Bars serve a broad range of functions in marine and offshore industries including:

Structural frames and supports on vessels, offshore platforms, and docks

Railings, guardrails, and ladders exposed to saltwater environments

Mounting brackets for marine equipment and electronics

Hull stiffeners and reinforcement members

Custom marine machinery components and enclosures

Transportation containers and crates for marine use

Advantages of 6061 T6 Marine Aluminum Flat Bar

Excellent Corrosion Resistance: Performs well in seawater and salt spray conditions, especially when anodized.

High Strength: Provides superior tensile and yield strength suited for demanding structural marine roles.

Weldability: Compatible with TIG, MIG, and arc welding methods with minimal loss of properties.

Good Machinability and Formability: Can be cut, drilled, bent, and shaped with standard fabrication tools.

Lightweight: Helps reduce vessel weight and improve fuel efficiency relative to steel alternatives.

Aesthetic Flexibility: Can be anodized or powder-coated offering corrosion resistance and color options.

Maintenance and Care Recommendations

To maximize the longevity and performance of 6061 T6 Marine Aluminum Flat Bars:

Clean surfaces regularly with fresh water to remove salt and detritus.

Avoid abrasive cleaners or tools that damage anodized or painted layers.

Inspect periodically for dents, corrosion, or mechanical damage, particularly at welded or bolted joints.

When necessary, touch up anodizing or protective coatings.

Use compatible fasteners and isolation to prevent galvanic corrosion in multi-metal assemblies.

6061 T6 Marine Aluminum Flat Bar is a superior marine alloy product combining high strength, corrosion resistance, and fabrication versatility, ideal for structural, framing, and equipment support applications in maritime environments. Its balance of ruggedness and lightweight properties makes it a preferred choice for both commercial and specialized marine projects.

Contact our technical sales team for precise product specifications, customized sizing, or engineering consultation to select the best 6061 T6 marine aluminum flat bar for your application.