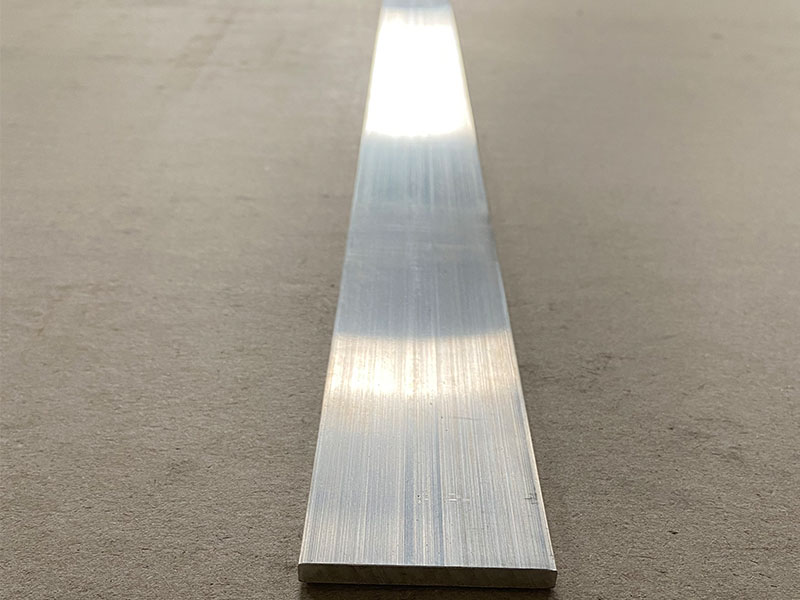

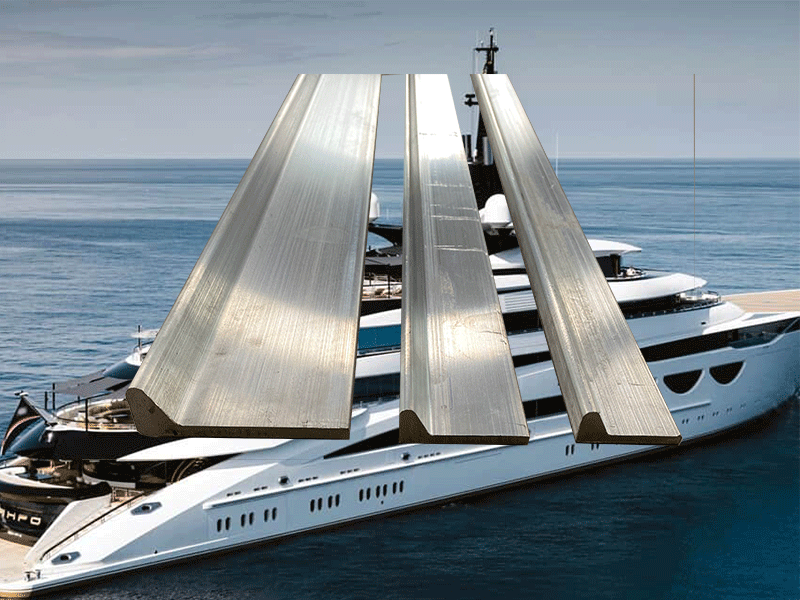

5083 Marine Aluminum Flat Bars are premium-grade aluminum alloy bars specially designed to meet the tough demands of marine and offshore environments. Renowned for their exceptional corrosion resistance, excellent strength-to-weight ratio, and outstanding durability, 5083 alloy flat bars serve as a critical component in shipbuilding, offshore platforms, coastal infrastructure, and marine fabrication applications.

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray. This alloy exhibits enhanced strength characteristics combined with remarkable toughness and weldability, making it an ideal choice for structural and functional elements exposed to harsh marine conditions.

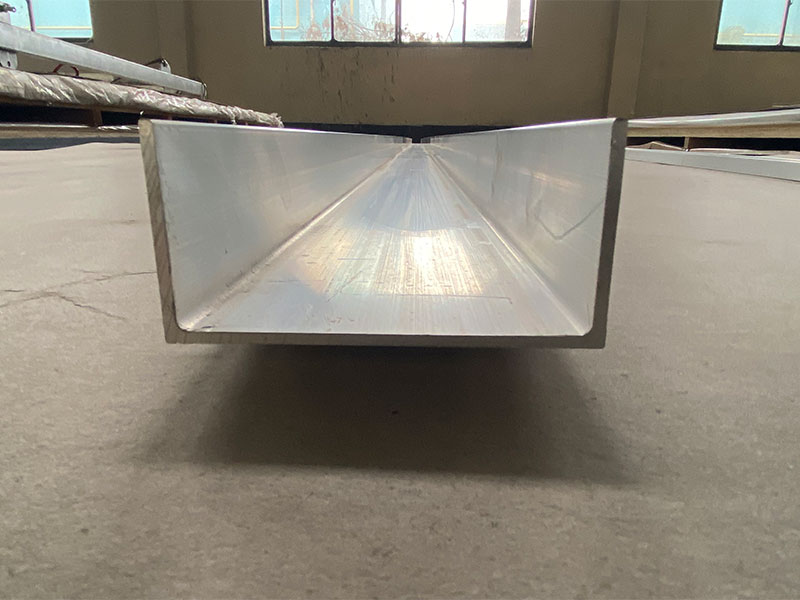

Manufactured via hot rolling and controlled finishing techniques, 5083 Marine Aluminum Flat Bars are supplied with consistent dimensional tolerances, smooth surfaces, and reliable mechanical qualities suitable for direct use or further fabrication.

Chemical Composition

The chemical formulation of 5083 aluminum ensures maximum corrosion protection and structural integrity:

| Element | Typical Content (%) |

|---|---|

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance |

Mechanical Properties

The mechanical characteristics of 5083 Marine Aluminum Flat Bars enable them to perform under demanding marine conditions:

| Property | 5083-H111 | 5083-H321 |

|---|---|---|

| Tensile Strength (MPa) | 275 – 345 | 290 – 350 |

| Yield Strength (MPa) | 125 – 215 | 145 – 215 |

| Elongation (%) | 12 – 24 | 10 – 18 |

| Hardness (Brinell) | 70 – 95 | 75 – 95 |

Physical Properties

Density: Approximately 2.66 g/cm³, offering substantial weight advantages over steel.

Thermal Conductivity: Around 121 W/m·K, facilitating heat dissipation in structural elements exposed to marine machinery or direct sunlight.

Melting Point: 570 – 640 °C, ensuring stability in a wide temperature range.

Electrical Conductivity: Moderate, about 28% IACS, useful for grounding and electrical conduction purposes onboard vessels.

Manufacturing Process

5083 Marine Aluminum Flat Bars are manufactured through the following major processes:

Hot Rolling: Molten aluminum is cast and passed through hot rollers to achieve the flat bar's specified thickness and width, ensuring strength and surface flatness.

Cold Working (As needed): Performed to reach the designated temper or mechanical characteristics, especially for applications requiring enhanced strength.

Finishing: Standard mill finish is supplied, with options for anodizing or painting to improve corrosion resistance and appearance.

Cutting and Fabrication: Custom cut-to-length services and fabrication options such as drilling, bending, and welding are available to meet project-specific requirements.

Typical Marine Applications

5083 Marine Aluminum Flat Bars are applied in a broad variety of marine and offshore activities, including:

Structural framing and reinforcements for ship hulls and superstructures.

Railings, ladders, and stair treads resistant to sea-air corrosion.

Support brackets and mounting platforms for marine machinery and electronics.

Load-bearing components of offshore oil and gas rigs.

Fabrication of marine trailers, docks, and pontoon frames.

Custom marine equipment housing and protective guards.

Advantages of 5083 Marine Aluminum Flat Bars

Outstanding Marine Corrosion Resistance: Defends effectively against seawater pitting, crevice corrosion, and salt spray.

High Strength and Toughness: Suitable for load-bearing and impact-resistant applications.

Excellent Weldability: Compatible with standard marine welding processes like MIG and TIG, maintaining corrosion resistance and mechanical performance in joints.

Good Formability: Allows bending, rolling, and shaping without cracking, enabling custom marine structural fabrication.

Lightweight Design: Enhances fuel efficiency and decreases structural weight compared to steel alternatives.

Long Service Life: Reduced maintenance and repair costs owing to robust corrosion protection and mechanical durability.

Maintenance and Care Recommendations

For prolonged usage and optimal performance of 5083 Marine Aluminum Flat Bars:

Regular Cleaning: Keep surfaces clean with freshwater washes to remove salt deposits and biofouling.

Avoid Abrasives: Use mild detergents and non-abrasive cleaning tools to preserve surface integrity.

Periodic Inspections: Monitor for signs of mechanical damage or corrosion, especially near welds and fasteners.

Protective Coatings: When operating in extremely aggressive environments, consider anodizing or marine-grade coatings for extra protection.

Proper Handling: Use compatible fasteners and ensure electrical isolation from dissimilar metals to prevent galvanic corrosion.

5083 Marine Aluminum Flat Bars offer marine engineers and fabricators an ideal combination of strength, corrosion resistance, and versatility needed for maritime and offshore applications. Their lightweight nature reduces overall structural weight while maintaining reliable performance in marine environments, ensuring safety and durability.

For detailed specifications, custom sizing, technical advice, or competitive quotations, please reach out to our knowledgeable sales and engineering team.