Marine Aluminum Channels are specialized aluminum structural profiles designed to meet the rigorous demands of marine and offshore environments. Engineered from marine-grade aluminum alloys, these channels offer an optimal combination of strength, corrosion resistance, lightweight characteristics, and fabrication versatility. Widely employed in shipbuilding, offshore structures, coastal infrastructure, and marine equipment fabrication, Marine Aluminum Channels provide durable and reliable structural solutions tailored for saltwater exposure and harsh weather conditions.

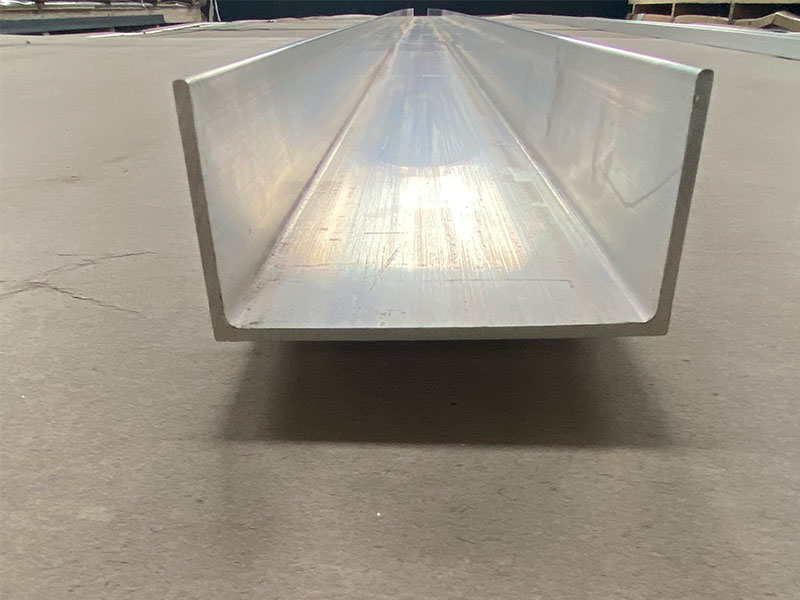

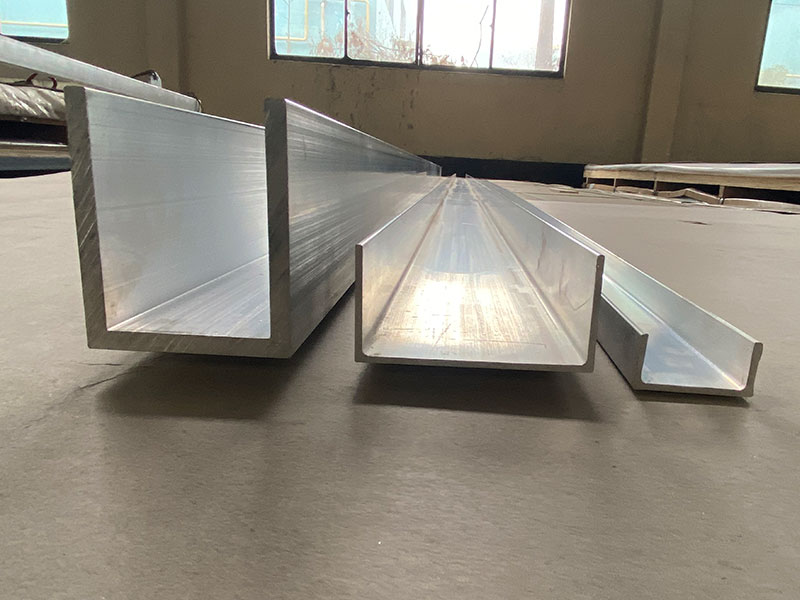

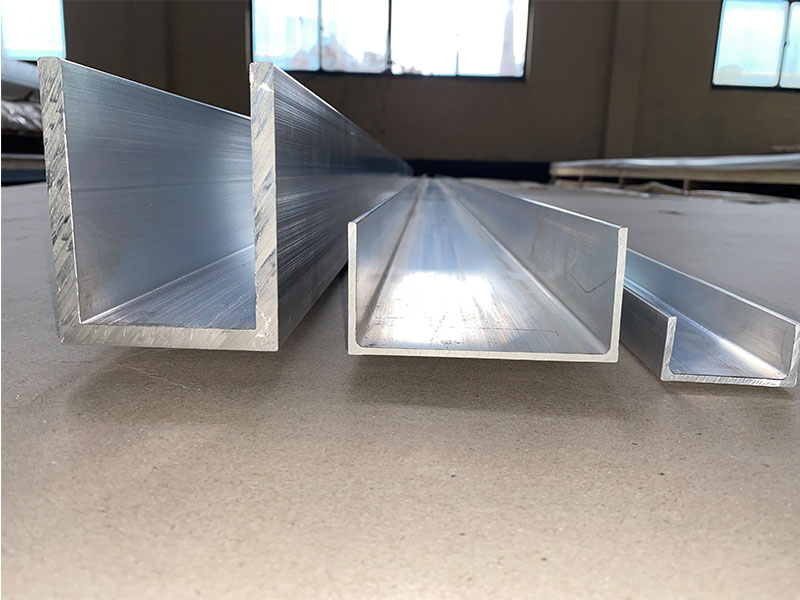

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength. These channels are commonly manufactured through extrusion or rolling processes to strict dimensional tolerances, ensuring consistent quality and structural integrity.

The channels provide excellent load-bearing support and are frequently utilized where weight savings are crucial without compromising strength or durability. Their corrosion-resistant nature reduces the risk of deterioration due to saltwater, preventing costly repairs and downtime over the service life.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Marine-Grade Aluminum Alloys | Typically 5xxx (5083, 5052) and 6xxx (6061) series alloys offering superior seawater resistance | Long-term corrosion resistance in salt spray and seawater |

| Lightweight Structural Profile | Density approximately 2.66 g/cm³, significantly lighter than steel | Simplifies installation and reduces vessel or structure weight |

| High Strength-to-Weight Ratio | Strong channel design enhances load-bearing capabilities with minimal added mass | Reliable structural performance with improved efficiency |

| Versatile Sizes and Thicknesses | Available in various dimensions and thickness to suit custom marine engineering needs | Flexibility to tailor structural components precisely |

| Excellent Fabricability | Easily cut, welded, drilled, and formed using standard marine fabrication equipment | Enables rapid customization and onsite modifications |

| Non-Magnetic & Non-Toxic | Suitable for electronics housings, potable water equipment, and sensitive marine uses | Compatibility with specialized marine systems |

Common Marine-Grade Aluminum Alloys for Channels

| Alloy | Composition & Characteristics | Typical Applications |

|---|---|---|

| 5083 | Mg 4.0-4.9%, Mn 0.4-1.0%, Cr 0.05-0.25%, excellent corrosion resistance and medium-high strength | Ship hull supports, structural frames |

| 5052 | Mg 2.2-2.8%, Cr 0.15-0.35%, excellent formability and corrosion resistance | Deck trimming, handrails, equipment frames |

| 6061 | Mg 0.8-1.2%, Si 0.4-0.8%, Cr 0.04-0.35%, Cu 0.15-0.4%, higher strength with good corrosion resistance when anodized | Load-bearing components, machined parts |

Mechanical Properties (Representative Values)

| Property | 5083-H321 | 5052-H32 | 6061-T6 |

|---|---|---|---|

| Tensile Strength (MPa) | 300 – 350 | 228 – 271 | 310 – 350 |

| Yield Strength (MPa) | 145 – 215 | 103 – 138 | 270 – 300 |

| Elongation (%) | 10 – 18 | 10 – 15 | 8 – 12 |

| Density (g/cm³) | 2.66 | 2.68 | 2.70 |

Manufacturing and Surface Treatments

Manufacturing: Marine aluminum channels are produced predominantly by extrusion or hot rolling, ensuring dimensional precision, uniform wall thickness, and high structural strength.

Lengths & Sizes: Standard lengths typically range from 6 meters to 12 meters, with custom sizing available. Channel depths commonly vary from 20 mm to 150 mm, with wall thickness from 2 mm to 10 mm or more.

Finishes: Mill finish is standard, while anodizing, powder coating, or painting enhances corrosion resistance and aesthetic quality. These surface treatments also increase lifespan in aggressive marine environments.

Typical Marine Applications

Framing and structural supports for ship superstructures and hull reinforcements

Handrails, ladders, and guardrails aboard vessels and offshore platforms

Cable trays and conduit supports in marine electrical installations

Brackets, mounting rails, and machinery frames for marine equipment

Edge trims, framing for windows and doors, and walkways in coastal and offshore infrastructure

Enclosures and housing frameworks for marine navigation and communication devices

Advantages Compared to Traditional Materials

| Aspect | Marine Aluminum Channels | Steel Channels | Stainless Steel Channels |

|---|---|---|---|

| Corrosion Resistance | Excellent in marine environments | Poor without coatings | Excellent but heavier and costly |

| Weight | Light (~2.66 g/cm³) | Heavy (~7.85 g/cm³) | Heavy (~7.7-8.0 g/cm³) |

| Maintenance | Low; naturally corrosion-resistant | High; requires protective painting | Moderate; maintenance for tarnish |

| Fabrication Ease | Easily machined, formed, welded | Moderate; requires special equipment | Difficult and expensive |

| Cost | Moderate initial cost | Low upfront but high lifecycle costs | High upfront cost |

Maintenance Guidelines

Regular Cleaning: Rinse channels with fresh water to remove salt and prevent salt-induced corrosion.

Surface Inspection: Check regularly for mechanical damage or corrosion, particularly at welded joints or fastener interfaces.

Avoid Abrasives: Clean with mild soaps and soft tools to preserve surface finish.

Protective Coatings: Reapply anodizing or marine-grade paint in highly exposed areas if necessary.

Electrical Isolation: Insulate from dissimilar metals to prevent galvanic corrosion.

Marine Aluminum Channels provide an optimal solution for structural and accessory components in marine, offshore, and coastal infrastructure projects. Their combination of corrosion resistance, strength, lightweight properties, and fabrication flexibility makes them indispensable in saltwater environments demanding durability and reliable performance.

For customized sizing, alloy selection, or expert consultation, our sales and technical support team is ready to assist you in specifying the perfect Marine Aluminum Channel for your application.