5052 Marine Aluminum Z Shaped Sections for Lightweight Offshore Marine Construction

5052 Marine Aluminum Z Shaped Sections: A Structural Shortcut To Lightweight Offshore Strength

When naval architects and offshore engineers discuss weight savings, they usually start with plates, beams, and stiffeners. But there is a less obvious structural hero quietly transforming lightweight offshore marine construction: 5052 marine aluminum Z shaped sections.

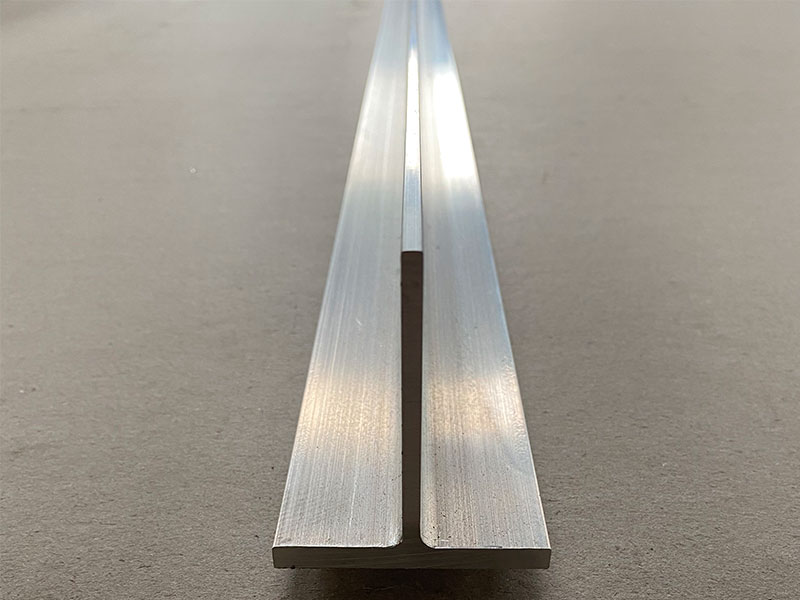

Z sections occupy a strange but powerful design space between flat plate and beam. They connect panels, stiffen decks, define edges, and provide continuous load paths around openings and transitions. When manufactured in corrosion-resistant 5052 marine aluminum, they become a kind of “structural punctuation” for offshore modules, workboats, floating docks, and accommodation blocks—light, durable, and surprisingly versatile.

Why Z Shaped Sections Matter In Marine Construction

Most marine sections are built around the same priorities: stiffness, weight control, and corrosion resistance. Z sections, however, bring an additional advantage: geometry-driven efficiency.

A Z profile can simultaneously:

- Tie two plates together in different planes

- Act as a flange and a stiffener at once

- Provide built-in offset between inner and outer skins

- Create clean attachment lines for panels, insulation, and cladding

In aluminum shipbuilding and offshore fabrication, this means a Z section can replace combinations of flat bars, angles, and brackets. Fewer parts, fewer welds, and less weight.

Using 5052 marine aluminum for the Z profile compounds the benefit: the alloy’s excellent corrosion resistance in seawater, good forming capability, and adequate strength make it ideal for these “connector” roles in hulls, topside modules, and lightweight superstructures.

5052 Aluminum: The Alloy Behind The Z

5052 is a non-heat-treatable aluminum–magnesium alloy known for:

- High resistance to saltwater and marine atmospheres

- Very good cold formability, ideal for bending Z shapes

- Moderate strength with good fatigue performance

- Good weldability with minimal loss of corrosion resistance

Instead of relying on heat treatment to increase strength, 5052 depends on its magnesium content and strain hardening. That makes it stable and predictable in the marine environment, where temperatures and local thermal inputs during welding can be difficult to control.

Where 5083 or 5383 might be chosen for heavily loaded hull girder structures, 5052 shines in secondary and tertiary structure: deck stiffeners, panel frames, joiner structures, walkways, and lightweight offshore housings where corrosion resistance and formability are more critical than maximum yield strength.

Typical Chemical Composition Of 5052 Marine Aluminum

Marine-grade 5052 used for structural Z sections follows established compositional limits. Typical values (weight percent) are:

| Element | Typical Range (%) | Role in Alloy |

|---|---|---|

| Mg | 2.2 – 2.8 | Primary strengthener; improves strain hardening and corrosion resistance |

| Cr | 0.15 – 0.35 | Controls grain structure; enhances toughness and corrosion resistance |

| Mn | ≤ 0.10 | Helps refine grain; minor strength contribution |

| Fe | ≤ 0.40 | Impurity control; excessive Fe can reduce toughness and ductility |

| Si | ≤ 0.25 | Impurity; controlled to maintain good corrosion behavior and formability |

| Cu | ≤ 0.10 | Kept low to preserve marine corrosion resistance |

| Zn | ≤ 0.10 | Minor impurity; restricted to avoid corrosion issues |

| Others | ≤ 0.05 each, ≤ 0.15 total | Trace elements kept low for predictable performance |

| Al | Balance | Matrix metal providing low density and basic structure |

This balanced profile allows 5052 Z sections to resist both general corrosion and pitting in chloride-rich seawater, especially when combined with proper surface preparation and coating where needed.

Mechanical Properties And Temper States For Z Profiles

From a design perspective, 5052’s value comes from its temper combinations and predictable mechanical behavior after forming. Z sections are usually manufactured by extrusion, roll forming, or press braking from 5052 sheet or plate. The forming method and target application determine the most suitable temper.

Common tempers for marine-grade 5052 Z shaped sections include:

O (Annealed)

Extremely ductile, ideal for severe forming and tight-radius Z bends. Lower strength but excellent for complex shapes or deep offsets.H32 (Strain-hardened and partially annealed)

A balanced temper offering good strength and still very good formability. Favored for many structural Z applications needing a compromise between bendability and load capacity.H34 / H36 (Higher strain hardening)

Higher strength, slightly reduced formability. Suitable where the Z section acts as a more heavily loaded stiffener or frame.

Typical mechanical properties for 5052-H32 used in marine Z sections (values approximate and dependent on standard and thickness):

- Tensile strength: around 215 – 260 MPa

- Yield strength (0.2% offset): around 130 – 195 MPa

- Elongation (in 50 mm): around 7 – 12%

The insight: because 5052 is non-heat-treatable, welding and moderate thermal exposure do not radically change its long-term behavior. That makes it stable for offshore modules and ship systems undergoing repeated modifications, hot work, and retrofits.

Geometry: What Defines A 5052 Z Section?

Unlike standard angles or channels, Z sections are highly tunable. Each profile can be optimized to answer a particular structural question: How much offset is needed? How stiff should the flange be? Where is the weld line?

Typical geometric parameters for marine Z profiles in 5052 include:

- Flange widths: often from about 30 mm up to 200 mm or more

- Web height: commonly from about 20 mm up to 150 mm

- Thickness: from about 2 mm for light joiner work up to 12 mm or higher for structural applications

- Root radius and bend radius: selected to ensure non-cracking forming in 5052, usually guided by minimum bend radius rules for each temper

Engineers often design custom Z profiles with:

- Asymmetric flange widths to place more material where loads are higher

- Offset web positions to match panel step heights or insulation thickness

- Integrated attachment ledges for bolted or bonded connections

The result is a functionally shaped connector rather than a generic stick of metal.

Implementation Standards And Certification Pathways

For offshore and marine work, 5052 Z sections must do more than “look strong.” They need to fit into recognized standards so classification societies and regulatory bodies can accept them without endless negotiation.

Typical standards and references that affect 5052 marine aluminum Z sections include:

- Standards for wrought aluminum products:

EN, ASTM, or equivalent national standards governing chemical composition, mechanical properties, tolerances, and testing of 5xxx series alloys - Marine-grade plate and extrusion guidelines:

Requirements from ISO, EN, or regional equivalents specifying marine applications of 5000-series alloys - Classification society rules:

Organizations such as DNV, ABS, LR, BV, CCS and others often provide guidance and acceptance criteria for aluminum structure, including:- Material certification and traceability

- Weld procedure qualification for 5xxx alloys

- Section modulus and scantling rules for aluminum hulls and superstructures

- Corrosion and protective system guidelines:

Coating systems, cathodic protection compatibility, and insulation details set by offshore and naval standards

From a design office perspective, this means 5052 Z sections can be incorporated into approved structural models, as long as:

- Alloy and temper are properly documented

- Thickness and profile meet or exceed minimum scantling rules

- Welding schedules reflect 5xxx-series best practices

- Corrosion allowance and coatings are accounted for in life-cycle design

A Different Way To Think About Z Sections: Structural Interfaces, Not Just Stiffeners

The distinctive advantage of a 5052 Z profile in marine and offshore builds is not only strength per weight. It is the ability to define interfaces between systems:

- Between hull skin and internal lining

- Between decks and bulkheads

- Between aluminum superstructures and mixed-material outfitting

- Between insulated panels and weather-exposed outer skins

Because 5052 bends, forms, and welds well, the Z section can adapt to these interfaces without dramatically increasing fabrication complexity. Consider a few examples of how offshore designers exploit this:

- In lightweight accommodation modules, a single 5052 Z section can act as a structural stiffener, insulation spacer, and panel mounting rail at the same time.

- In workboat and patrol vessel decks, Z profiles provide integrated channels for cabling and pipes, while also working as transverse stiffeners.

- In floating platforms and gangways, Z shapes can define the interface between anti-slip deck plating and side shell, creating a bolting edge, drip line, and structural tie-in in one piece.

From this perspective, the Z shape is a systems engineering tool as much as it is a structural element.

Corrosion Behavior And Surface Conditioning

In the offshore environment, bare aluminum is often expected to coexist with saline spray, immersion, and cyclic wet–dry conditions. 5052’s magnesium content and chromium additions give it a natural advantage:

- Excellent resistance to general corrosion in seawater

- Good resistance to pitting and crevice corrosion, provided design avoids long-term stagnant water traps

- Compatibility with marine-grade anodizing and paint systems

When used for Z sections, certain details help preserve corrosion performance:

- Smooth bend radii reduce local strain and micro-cracking during forming

- Avoiding galvanically dissimilar fasteners or inserts in direct contact without isolation

- Proper sealing around cut ends and welds, with edge preparation for coatings

In some offshore designs, 5052 Z sections are intentionally left uncoated in sheltered interior spaces, relying on the natural oxide layer for protection and reducing maintenance. In external or splash-zone use, high-performance paint systems or anodizing are typically applied, with careful control of surface roughness and pretreatment.

Weldability And Joint Design For Z Shape Applications

A Z section’s performance is often governed more by how it is welded and joined than by its base metal strength. 5052 behaves predictably during welding with common processes such as MIG and TIG, especially with suitable filler wires from the 5xxx family.

weldability characteristics relevant to Z sections:

- Low susceptibility to hot cracking due to controlled Cu and Si content

- Retention of good corrosion resistance in weld metal and heat-affected zone with correct filler choice

- Modest strength reduction near welds, generally acceptable for lightly to moderately loaded structures

In practical design terms:

- Continuous fillet welds along the Z flange can act as both structural and sealing joints between plates

- Spot or intermittent welds reduce heat input and distortion where full continuity is not required

- Z profiles can be oriented so that welds are accessible for inspection and future repairs, which is vital in offshore environments

Because 5052 is not heat-treatable, there is no need for complex post-weld heat treatment. Dimensional control and distortion management instead become the main fabrication challenges, especially for long slender Z sections used as stiffeners.

Design Advantages In Lightweight Offshore Construction

The argument for 5052 Z sections in offshore and marine applications becomes especially strong when weight and integration are critical.

In lightweight construction, Z profiles in 5052 contribute by:

- Reducing part count: a single Z can replace multiple angles and flat bars

- Allowing thinner plates: by stiffening strategically, designers can use thinner skins without compromising performance

- Improving installation sequencing: Z shapes provide clear mounting edges for modular panels, equipment racks, and services

- Supporting modularity and retrofits: standard Z profiles can be reused across different module sizes and vessel classes

Weight saved at the top of a structure has a significant effect on stability and motion response. By using 5052 Z sections in superstructures, accommodation blocks, and elevated platforms, designers can reduce overall vertical center of gravity, improving vessel behavior and lowering fuel consumption.

Typical Dimensional And Performance Parameters At A Glance

To tie parameters, properties, and practical use together, consider a typical range for marine-grade 5052 Z profiles:

- Alloy: 5052, marine grade

- Temper options: O, H32, H34, H36 depending on load and form requirements

- Thickness range: approximately 2 – 12 mm for most marine stiffeners and interfaces

- Flange width: often 30 – 200 mm, customized for load and connection details

- Web depth: typically 20 – 150 mm, tuned to stiffness requirements and panel spacing

- Tensile strength (in H32): roughly 215 – 260 MPa

- Yield strength (in H32): roughly 130 – 195 MPa

- Elongation: typically 7 – 12% in structural thicknesses

- Density: about 2.68 g/cm³, providing a significant weight advantage over steel alternatives

These values allow naval architects to calibrate FEA models and scantling calculations with confidence, knowing that 5052’s behavior is well-documented and stable in marine conditions.

A Unique Role In The Marine Aluminum Ecosystem

Within the broader family of marine aluminum alloys and profiles, 5052 Z shaped sections occupy a unique niche:

- They are not the highest-strength members of the structural hierarchy.

- They are not the thickest plates or the heaviest frames.

- Instead, they are the connective tissue that holds panels, decks, linings, and modules together.

By blending:

- The corrosion resistance and formability of 5052

- The geometric versatility of Z profiles

- Compliance with marine and offshore implementation standards

these sections enable designers to think in terms of integrated lightweight systems, not just isolated beams and plates.

For shipyards, offshore fabricators, and design offices focused on performance, durability, and ease of assembly, 5052 marine aluminum Z shaped sections offer a pragmatic yet quietly innovative path toward lighter, cleaner, and more maintainable offshore structures.

Related Products

Marine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsRelated Blog

5052 Marine Aluminum Angles for Durable Marine Frame Solutions

5052 Marine Aluminum Angles for Durable Marine Frame SolutionsA technical, application‑driven perspective5052 marine aluminum angles are a backbone material in modern shipbuilding and offshore structures—quietly underpinning decks, bulkheads, ra.

View Details5052 Marine Aluminum Z Shaped Sections for Lightweight Offshore Ship Design

5052 marine aluminum Z shaped sections deliver high strength-to-weight performance, excellent corrosion resistance, and easy weldability for lightweight offshore ship design.

View Details5052 Marine Aluminum Angles for Custom Coastal Engineering

In the dynamic field of coastal engineering, material selection plays an indispensable role in the longevity, reliability, and safety of offshore and shoreline structures.

View Details5052 Marine Aluminum Z Shaped Sections for Heavy Duty Offshore Design

Marine aluminum plays a crucial role in the formation of innovative and dependable solutions within the maritime industry due to its lightweight and excellent resilience to corrosion.

View Details5052 Marine Aluminum Z Shaped Sections for Corrosion Resistant Marine Frames

5052 aluminum alloy is widely recognized in the marine industry for its excellent corrosion resistance, formability, and weldability. This lightweight alloy is particularly suitable for marine applications.

View Details5052 Marine Aluminum Angles for Heavy Duty Marine Applications

In the world of marine applications, the choice of materials can significantly influence performance and longevity. For heavy-duty usage, marine aluminum angles, particularly 5052 Marine Aluminum angles, come out as premier contenders.

View Details

Leave a Message