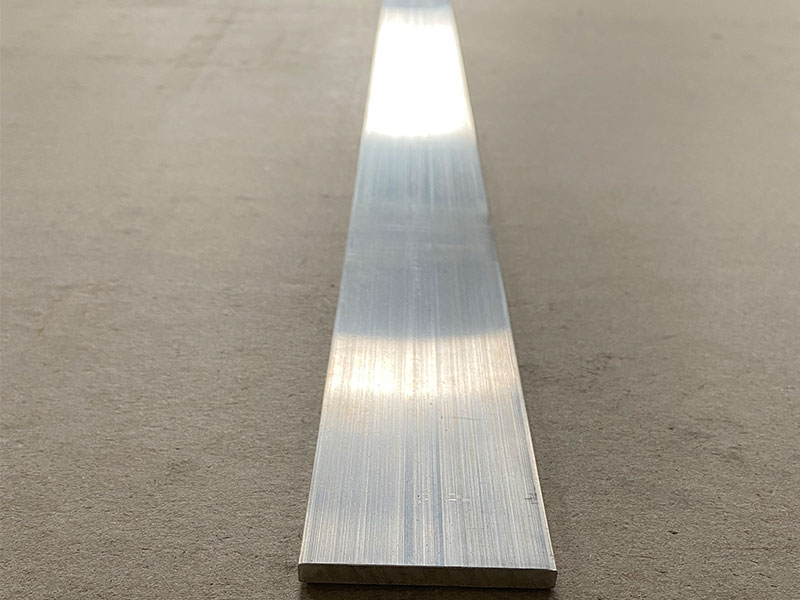

5052 Marine Aluminum Bar for Coastal Marine Engineering Projects

The 5052 marine aluminum bar is a premium product dedicated to the scrupulous requirements of coastal marine engineering projects. It stands out due to its excellent corrosion resistance, weldability, and formability, making it highly suitable for various marine applications.

Features

- Corrosion Resistance: Exceptional resistance to chloride environments helps maintain structural integrity, especially in salinized water or environments.

- Weldability: Good weld strength is conducive for fabrication processes and assembly, which are vital in marine structures.

- Formability: The aluminum can be cold-shaped into parts like brackets, fittings, or integral components of larger assemblies.

- Strength: High strength-to-weight ratio facilitates lighter structures without sacrificing durability or stability, particularly important in marine vessels.

- Temperature Stability: Retains physical properties over varying maritime temperature conditions.

Applications

The 5052 marine aluminum bar finds its implementations in various aspects of the marine industry, such as:

- Boat Structures: Usage in steps, rails, and frames due to its anti-corrosive properties.

- Marine Engineering Projects: Studded on offshore platforms and slipways, ensuring safety and resilience.

- Deck Hardware: Ideal for brackets, mount plates, and fasteners that require longevity with minimal maintenance.

- Support Beams: Offers a durable solution for reinforcement in superstructures like piers.

Chemical Composition

The performance characteristics of the 5052 aluminum alloy are largely determined by its chemical makeup. Below is a table displaying its composition:

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 2.2 - 2.8 |

| Manganese (Mn) | 0.10 - 0.50 |

| Chromium (Cr) | 0.15 - 0.25 |

| Silicon (Si) | 0.25 (max) |

| Iron (Fe) | 0.40 (max) |

| Copper (Cu) | 0.10 (max) |

| Zinc (Zn) | 0.10 (max) |

Technical Specifications

When considering 5052 marine aluminum bar, it is essential to be aware of the specifications that reflect its suitability for marine environments:

| Parameter | Specification |

|---|---|

| Alloy Designation | 5052 |

| Temper | H32, H34 |

| Density | 2.68 g/cm³ |

| Yield Strength | 193 MPa |

| Ultimate Tensile Strength | 228 MPa |

| Elongation - % | 12 - 20 |

| Hardness | 60 - 70 HB |

| Fatigue Strength | 84 MPa (A1) |

| Temperatures Range | -40°C to +65°C |

Related Products

Marine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsRelated Blog

5052 Marine Aluminum Hollow Bars for Offshore Engineering Solutions

In the domain of offshore engineering, material selection is critical to ensure the resilience, functionality, and longevity of maritime structures. Among various alloys.

View Details5052 Marine Grade Aluminum Solid Bar for Saltwater Proof Marine Structures

Superior corrosion resistance and mechanical properties of 5052 Marine Grade Aluminum Solid Bar, engineered for durable and reliable saltwater-proof marine structures. Learn about its chemical composition, alloy tempering, implementation standards, and ke

View Details5052 Marine Aluminum Bar for Coastal Marine Engineering Projects

The 5052 marine aluminum bar is a premium product dedicated to the scrupulous requirements of coastal marine engineering projects. It stands out due to its excellent corrosion resistance, weldability, and formability.

View Details5052 Marine Grade Aluminum Solid Bar for Lightweight Offshore Components

As the maritime industry continues to evolve toward efficiency and performance optimization, the choice of materials plays a pivotal role in determining the success of marine designs.

View Details5083 5052 H32 60mm aluminum bar for boat

High-performance 5083 and 5052 H32 60mm aluminum bars tailored for marine applications. Ideal for boat building with excellent corrosion resistance, superior strength, and formability.

View Details5052 Marine Grade Aluminum Solid Bar for Saltwater Tolerant Boat Parts

High-performance 5052 marine grade aluminum solid bar, engineered for superior corrosion resistance and durability in saltwater environments. Ideal for boat parts and marine applications demanding long-lasting strength and reliability.

View Details

Leave a Message