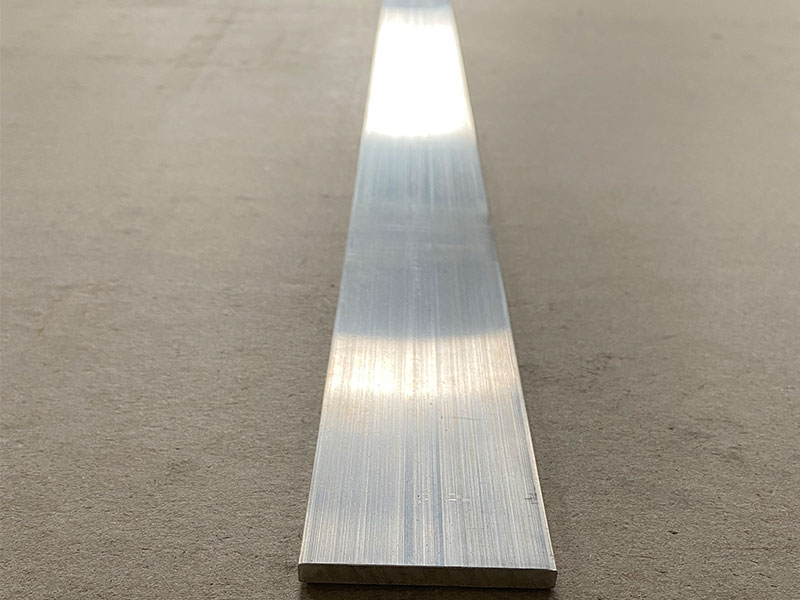

5052 Marine Aluminum Hollow Bars for Offshore Engineering Solutions

In the domain of offshore engineering, material selection is critical to ensure the resilience, functionality, and longevity of maritime structures. Among various alloys, 5052 Marine aluminum hollow bars have emerged as a fantastic solution owing to their unique combination of properties, aligning with the stringent demands of the marine environment.

What is 5052 Marine Aluminum?

Alloy 5052 is one of the most durable aluminum alloys produced, designed particularly for marine and offshore applications. Characterized by its excellent corrosion resistance, 5052 marine aluminum attributes its remarkable performance to the presence of magnesium as its primary alloying element.

Technical Specifications and Properties

Parameters

| Parameter | Specification |

|---|---|

| Alloy Type | 5000 Series, 5052 |

| Major Alloying Element | Magnesium (2.2-2.8%) |

| Yield Strength (typically) | 210 MPa |

| Ultimate Tensile Strength (typical) | 330 MPa |

| Density | 2.68 g/cm³ |

| Corrosion Resistance | Excellent |

| Thermal Conductivity | 138 W/mK |

| Thermal Expansion | 24 x 10^-6 °C^-1 |

| Machinability | Good |

Alloy Tempering and Conditions

Alloy tempering is a critical aspect of optimizing 5052 aluminum's properties. The standard temper for marine applications is often H32, which indicates half-hard status produced through a combination of cold working and solution treatment. considerations include:

- H111: Work-hardened with stable physical properties, enhancing resistance to corrosion.

- O: Annealed temper enhancing compatibility for various welding methods.

- H34: Obtained through minor cold-working, maintaining stability while providing increased tensile strength.

Each temper responds uniquely to marine conditions, confirming practical application in offshore environments.

Functions and Benefits of 5052 Marine aluminum hollow bars

Marine aluminum hollow bars are ingeniously designed to redefine the concept of durability across the maritime landscape. functions and benefits include:

1. Strength-to-Weight Ratio

With processes demanding lightweight materials combined with strength to withstand harsh sea conditions, 5052 hollow bars offer an unmatched strength-to-weight ratio, significantly boasting energy efficiency and enhancing payload capacities in offshore engineering constructs.

2. Corrosion Resistance

Aluminum's natural oxidation creates a shield from the corrosive effects of saltwater. Given that 5052 hollow bars possess finer surface morphologies, their excellent resistance to marine atmospheres surpasses myriad metals standards, prolonging the life-span of applications from shipbuilding to offshore drilling frames.

3. Versatile Applications

The application of 5052 Marine aluminum hollow bars spans across several tiers of offshore engineering solutions. Effectively, they are employed in structural supports, vessel hull applications, various housing installations in shipbuilding, manufactured buoy systems, facilitation of marine pipelines, and configurations of jack-up rigs.

Implementation Standards

Ultimately, high-quality offshore engineering demands compliance with internationally established standards. Accordingly, 5052 marine aluminum necessitates stringent adherence to codes including:

- ASTM B929: Aluminum-coated steel wire enhancing tarnish resistance.

- MIL-R-46099: Assessing the specifics in military-grade applications which ensure coverage on preventing quick degradation in chemical agents.

A Unique Diction in Technology Circles

added technical depths elicits a unique distinction—structural innovations often endeavor complex designs manifesting as aqueous constraints. Notably, facilities employing 5052 moc’hollow bars maneuver within realms prioritizing ergonomics revolving around buoyancy those rend seamless puzzle solving fears surrounding joints and rotational conformance permeates meets liquidity.

Related Products

6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsRelated Blog

5052 Marine Grade Aluminum Solid Bar for Lightweight Offshore Components

As the maritime industry continues to evolve toward efficiency and performance optimization, the choice of materials plays a pivotal role in determining the success of marine designs.

View Details5052 Marine Aluminum Bar for Coastal Marine Engineering Projects

The 5052 marine aluminum bar is a premium product dedicated to the scrupulous requirements of coastal marine engineering projects. It stands out due to its excellent corrosion resistance, weldability, and formability.

View Details5083 5052 H32 60mm aluminum bar for boat

High-performance 5083 and 5052 H32 60mm aluminum bars tailored for marine applications. Ideal for boat building with excellent corrosion resistance, superior strength, and formability.

View Details5052 Marine Grade Aluminum Solid Bar for Saltwater Tolerant Boat Parts

High-performance 5052 marine grade aluminum solid bar, engineered for superior corrosion resistance and durability in saltwater environments. Ideal for boat parts and marine applications demanding long-lasting strength and reliability.

View Details5052 Marine Grade Aluminum Solid Bar for Saltwater Proof Marine Structures

Superior corrosion resistance and mechanical properties of 5052 Marine Grade Aluminum Solid Bar, engineered for durable and reliable saltwater-proof marine structures. Learn about its chemical composition, alloy tempering, implementation standards, and ke

View Details5052 Marine Aluminum Hollow Bars for Offshore Engineering Solutions

In the domain of offshore engineering, material selection is critical to ensure the resilience, functionality, and longevity of maritime structures. Among various alloys.

View Details

Leave a Message