5083 Marine Aluminum Tubes for Saltwater Proof Boat Hulls

When builders talk about a saltwater-proof boat hull, the conversation often gets stuck on a single idea: corrosion resistance. That's necessary, but it's not the whole story. A hull is not a static object; it is a living structure that flexes, vibrates, absorbs impact, cycles through temperature swings, and constantly negotiates with chloride-rich seawater. From this perspective, 5083 marine aluminum tubes are not just "parts" that go into a hull. They behave like a structural circulatory system-carrying loads along frames, stringers, lattice members, and deck substructures while quietly resisting the slow chemical "weathering" that saltwater wants to impose.

This is why 5083 aluminum tube (Al-Mg alloy) has become a benchmark in marine fabrication: it combines excellent seawater corrosion resistance, strong as-welded performance, and reliable toughness for hull structures that must survive real ocean conditions rather than laboratory promises.

Why 5083 Aluminum Tubes Make Hulls Feel "Saltwater-Proof" in Real Service

The distinctive advantage of 5083 is not a magical coating effect. It's metallurgical behavior.

Saltwater corrosion is aggressive because chloride ions attack protective surface films on many metals. 5083 forms a stable aluminum oxide film, and its magnesium alloying supports a corrosion-resisting profile that performs exceptionally well in marine atmospheres and immersion environments. More importantly, 5083 is widely trusted for welded hull assemblies because it does not rely on heat-treatment strength that would be destroyed by welding in the first place.

A tube used in a boat hull is often a load path that sees bending and local buckling forces. The marine builder's reality is that structural elements must remain robust even after fabrication heat input, fit-up correction, and long-term cyclic motion. 5083 marine aluminum tubes are chosen because they hold their integrity in those messy, real manufacturing conditions.

What "Saltwater-Proof" Really Means for a Tube-Based Hull Structure

A hull built with tubes is essentially an engineered skeleton. Tubes are efficient because they provide high stiffness-to-weight, but they also introduce concentration points at weld toes, cut ends, drainage points, and bracket connections. So "saltwater-proof" must account for:

Resistance to pitting and crevice corrosion in splash zones and bilge areas

Compatibility with welded fabrication, including HAZ behavior and joint integrity

Fatigue resilience under wave slam, engine vibration, and repeated flexing

Galvanic management when other metals are nearby (fasteners, fittings, bonded systems)

5083 does not eliminate the need for good marine design, but it reduces the metal's tendency to become the weak link.

Typical Applications of 5083 Marine Aluminum Tubes in Boat Hulls

Boat hull performance often depends on what you don't see. 5083 tubes frequently show up as:

Hull frames and transverse members where stiffness and corrosion resistance must coexist

Stringers and longitudinals that carry bending loads along the hull

Deck beams, superstructure supports, T-top frames, and catamaran cross members

Pipe-like structural members used to reduce weight while keeping rigidity high

Where weight savings directly improves speed, fuel efficiency, and payload, 5083 aluminum tubing becomes a strategic structural choice rather than a commodity.

Parameters That Matter: Dimensions, Tolerances, and Surface Condition

A marine tube is not simply "round aluminum." The parameters that most influence success in a boat hull include:

Outer diameter and wall thickness chosen to prevent local buckling under compressive wave loads

Straightness and ovality control to keep weld gaps consistent and reduce distortion

Surface finish to reduce crevice traps and improve coating adhesion if coatings are used

End preparation and drainage detailing to avoid stagnant saltwater pockets inside sections

Manufacturers commonly supply tubes in a range of OD and wall thickness combinations based on project needs. In hull skeletons, designers often prefer thicker walls than non-marine applications, because marine structures live in a world of impacts, point loads, and weldments.

Alloy Tempering and Condition: Why H116 and H321 Dominate Marine Use

For 5083 marine aluminum, temper is more than a strength label-it's a durability decision.

5083-H116 is widely specified for marine plate and structural components because it is processed to improve corrosion performance in marine environments, particularly resistance to exfoliation and stress corrosion behavior in typical seawater service.

5083-H321 is also common in marine structures and is stabilized after rolling, helping maintain good mechanical properties and service reliability.

5083-O exists as fully annealed material, useful when extreme forming is required, but it is generally not the first choice for structural hull members where strength is central.

For boat hull tubes, H116 and H321 are frequently preferred because they represent a balanced "marine-ready" condition-good strength, good weldability, and excellent corrosion resistance.

Implementation Standards and Common Marine Specification Expectations

Marine aluminum is only as trustworthy as its documented compliance. Depending on region and project, 5083 aluminum tubes for hull structures are often produced or verified to standards such as:

ASTM B241/B241M for seamless aluminum and aluminum-alloy pipe and tube

EN 755 series for aluminum extrusions (often applicable when tubes are extruded)

ISO and marine classification expectations for structural documentation, traceability, and inspection practices

Welding standards frequently referenced in marine builds, including AWS D1.2 for structural welding of aluminum

In real boatbuilding, the "standard" isn't just paperwork. It affects chemical limits, mechanical properties, inspection requirements, and the repeatability of tube performance across multiple hulls.

Welding and Fabrication: The Tube's "Truth Test" in Hull Construction

A unique advantage of 5083 in a tube-based hull system is how it behaves after welding. Because 5083 is not strengthened by precipitation heat treatment like 6xxx or 7xxx alloys, it avoids the dramatic post-weld strength drop associated with heat-treatable alloys. That makes it highly practical for hull frameworks with many joints.

Common marine welding practices include:

GMAW (MIG) and GTAW (TIG) processes, chosen based on section thickness and access

Typical filler metals such as ER5356 or ER5183 depending on strength and corrosion requirements

Attention to heat input, joint design, and cleaning to avoid porosity and lack of fusion

A tube structure also demands smart detailing: smooth transitions, minimized notch effects, and proper drainage/venting if tubes are sealed or partially enclosed.

Chemical Properties Table: 5083 Marine Aluminum Alloy Composition

5083 is an Al-Mg alloy with manganese and chromium additions that contribute to strength and corrosion behavior. The table below lists typical composition limits used in common specifications (exact limits can vary slightly by standard and mill practice).

5083 Aluminum Alloy Chemical Composition (Typical Limits, wt%)

| Element | Composition (wt%) |

|---|---|

| Aluminum (Al) | Remainder |

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Silicon (Si) | ≤ 0.40 |

| Iron (Fe) | ≤ 0.40 |

| Copper (Cu) | ≤ 0.10 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

This chemistry helps explain why 5083 "feels" marine-native: magnesium supports strength and corrosion performance, while Mn and Cr contribute to structural stability and resistance characteristics important for long-life seawater exposure.

Mechanical Property Expectations: What Builders Typically Target

Mechanical properties vary with temper, thickness, and product form. For marine hull tube applications, designers typically align their expectations with H116 or H321 property ranges. The is not only ultimate strength but also yield strength, elongation, and toughness-because boats don't fail only by overload; they fail by fatigue, denting, and long-term cyclic damage.

If you're specifying tubes for a saltwater boat hull, it's best to confirm:

Temper designation and certification

Minimum yield and tensile strength requirements tied to thickness

Inspection requirements for dimensional accuracy, surface quality, and traceability

Corrosion Reality Check: How 5083 Helps You Win the "Hidden Battles"

Saltwater corrosion often starts where nobody looks: under insulation, inside wet bilges, at lap joints, at poorly drained tube ends, beneath deposits, or in crevices around brackets. 5083's corrosion resistance gives you margin, but a truly saltwater-proof hull mindset includes:

Avoiding dissimilar metal contact without isolation strategies

Designing drainage paths so seawater doesn't become trapped

Using proper surface preparation before coating or painting

Preventing crevices where stagnant chloride solutions can concentrate

In other words, 5083 is a powerful baseline material, and good marine engineering turns that baseline into decades of service life.

The Bottom Line: 5083 Marine Aluminum Tubes as a Hull "Insurance Policy"

From the "living structure" viewpoint, 5083 marine aluminum tubes work because they balance what boat hulls actually demand: corrosion resistance under chloride attack, structural reliability after welding, and strength that supports lightweight design without sacrificing ruggedness. When produced to recognized standards and specified in marine-appropriate tempers such as H116 or H321, 5083 becomes one of the most dependable choices for builders who want a hull that stays strong, clean, and serviceable in the long relationship between metal and sea.

Related Products

Marine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

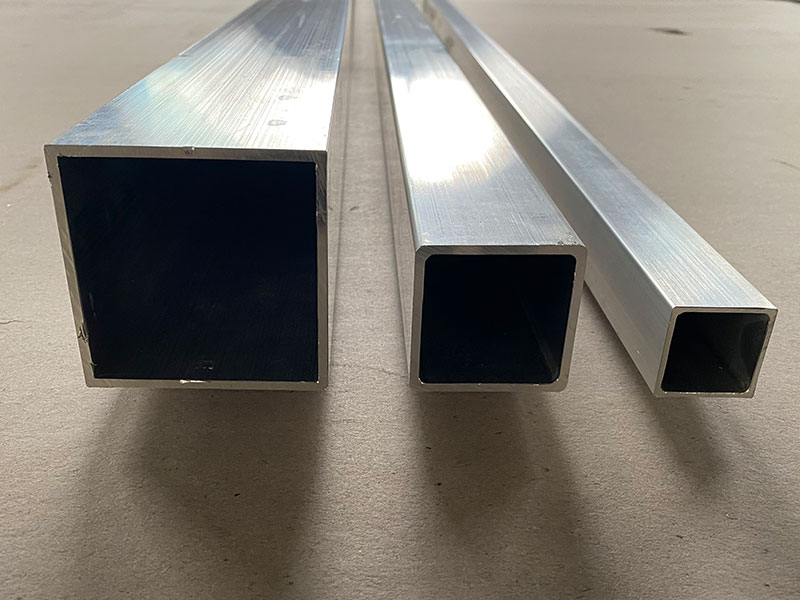

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

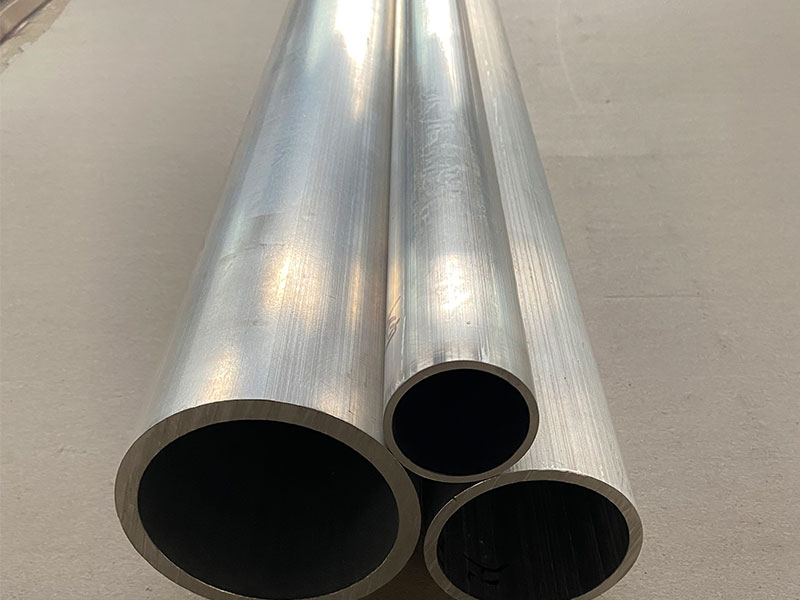

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Coastal Boat Engineering Solutions

In coastal boat engineering, selecting materials that offer superior performance, durability, and resistance to harsh marine environments is critical. 5083 marine aluminum tubes present an exceptional solution.

View Details5083 Marine Aluminum Tubes for Saltwater Environment Durability

When it comes to marine applications, durability, corrosion resistance, and mechanical performance are paramount for structural materials. Among the various aluminum alloys available, 5083 aluminum alloy stands out as a premium choice.

View Details5083 Marine Aluminum Tubes for Coastal Boat Building

Marine Aluminum is a prominent material in the marine industry due to its exceptional properties, which makes it the perfect choice for constructing strong, lightweight vessels.

View DetailsAluminum 5083 Marine Pipe Elbow for Ship Building Projects

Aluminum 5083 marine pipe elbows are essential fittings used in shipbuilding and maritime systems where strength, corrosion resistance, and lightweight construction are critical.

View Details5083 Marine Aluminum Tubes for Offshore Oil and Gas Platforms

5083 marine aluminum tubes are widely used in offshore oil and gas platform structures where a combination of high strength, exceptional corrosion resistance and good weldability is required.

View Details5083 Marine Aluminum Tubes for Ship Hull Reinforcement Materials

When it comes to building and reinforcing ship hulls, selecting the right material is critical for durability, strength, and resistance to the harsh marine environment.

View Details

Leave a Message