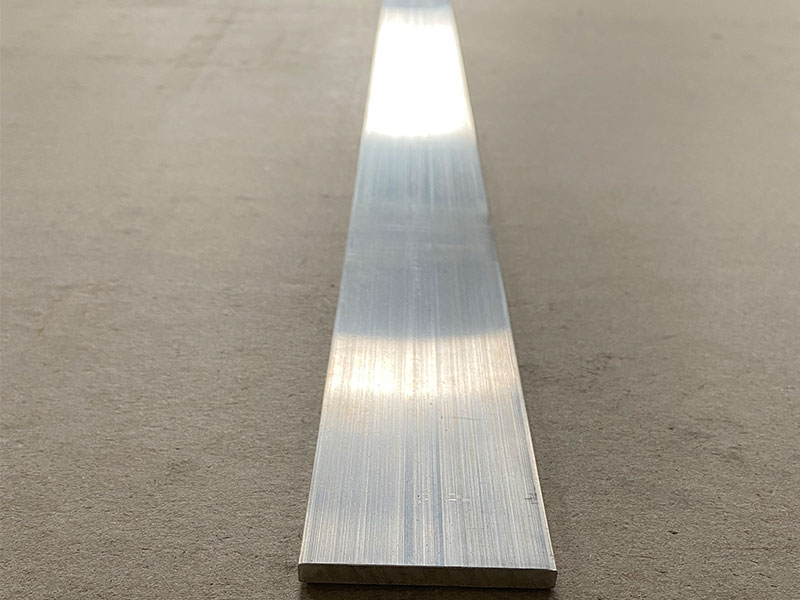

5052 Marine Grade Aluminum Solid Bar for Marine Component Durability

5052 Marine grade aluminum solid bar: A Durability Mindset, Not Just a Material Choice

Shipbuilders rarely talk about aluminum as “just metal.” In modern marine engineering, 5052 Marine grade aluminum solid bar is more like a design philosophy: a way to lock long-term durability, weight efficiency, and corrosion resistance into the DNA of a vessel.

Instead of asking, “What does 5052 bar do?” a better question is, “What kind of failures does 5052 bar quietly prevent over years at sea?” From that vantage point, its technical parameters, standards, tempers, and chemistry are not abstract data—they are risk-control tools.

Why 5052 Solid Bar Succeeds Where Other Metals Slowly Fail

In marine environments, most metals don’t fail dramatically; they fail gradually. Bolts seize. Shafts pit. Brackets thin out under crevice corrosion. Fasteners lose preload. When you choose 5052 solid bar for marine components—pins, shafts, cleats, brackets, valve bodies, reinforcement bosses—you are deliberately selecting a microstructure that resists this silent degradation.

Where high-strength steels may bring spectacular tensile numbers but demand vigilant coating maintenance, 5052 offers a different value proposition: medium strength, high ductility, robust corrosion resistance, and outstanding workability. It’s the metal that forgives installation misalignment, absorbs shock loading, and survives imperfect maintenance schedules.

The Density–Strength Paradox: Why “Just Strong Enough” Is Ideal at Sea

5052 is not the strongest aluminum alloy. That’s deliberate, not a flaw. For marine components, maximum strength is less critical than reliable performance under repeated real-world abuse.

In applications such as:

- Tiller arms

- Rudder and steering linkages

- Deck hardware bases

- Pump and winch mounting lugs

- Bracing for housings, rails, and ladders

5052 solid bar sits in the structural “sweet spot”: it is strong enough to carry sustained loads, yet ductile enough to avoid brittle fracture when hit by wave slams, accidental impacts, torsional misalignment, or temperature fluctuations.

Its relatively low density (about 2.68–2.72 g/cm³) multiplies that benefit. Every kilogram saved aloft or forward helps with trim, stability, and fuel economy. When you choose 5052 bar for repeated-use hardware instead of heavier metals, you are effectively engineering in weight savings every time a component is duplicated across the vessel.

The Alloy Behind the Performance: Chemistry as a Corrosion Strategy

5052 is an aluminum–magnesium alloy with trace elements carefully controlled to balance strength, formability, and corrosion resistance. Its composition is not random; every element operates like a “dial” that designers have tuned toward marine performance.

Typical chemical composition of 5052 marine grade aluminum:

| Element | Content (wt. %) |

|---|---|

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Manganese (Mn) | ≤ 0.10 |

| Iron (Fe) | ≤ 0.40 |

| Silicon (Si) | ≤ 0.25 |

| Copper (Cu) | ≤ 0.10 |

| Zinc (Zn) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.03 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

| Aluminum (Al) | Balance |

From a marine durability perspective, some features of this chemistry stand out:

- Magnesium is the backbone of strength and work-hardening. It boosts mechanical properties while maintaining excellent corrosion resistance.

- Chromium stabilizes the microstructure and helps resist intergranular corrosion, supporting durability under welding and bending.

- Low copper content is intentional. Copper increases strength but can severely harm corrosion performance in saltwater. By keeping Cu low, 5052 avoids galvanic tendencies that would accelerate pitting.

In other words, the chemistry of 5052 is a carefully negotiated compromise: enough alloying for strength, but not so much that corrosion becomes a trade-off.

Mechanical Parameters: Turning Chemistry into Usable Strength

For a designer or marine engineer, alloy composition is interesting, but design calculations depend on mechanical properties. 5052 is typically supplied in several tempers, with H32 and H34 being especially meaningful for marine solid bar used in components that will see both static and dynamic loads.

Typical mechanical properties for 5052 aluminum solid bar (room temperature):

| Property | 5052-O (Annealed)* | 5052-H32 | 5052-H34 |

|---|---|---|---|

| Temper description | Soft, fully annealed | Strain-hardened, stabilized | Higher strain-hardened, stabilized |

| Tensile strength (MPa) | ~ 170 | 215 – 265 | 230 – 280 |

| Yield strength (0.2% offset, MPa) | ~ 65 | ≥ 160 | ≥ 180 |

| Elongation (%) | 18 – 25 or higher | 7 – 12 | 6 – 10 |

| Brinell hardness (HB) | ~ 45 | ~ 60 – 70 | ~ 65 – 75 |

| Modulus of elasticity (GPa) | ~ 70 | ~ 70 | ~ 70 |

| Shear strength (MPa) | ~ 100 | ~ 125 – 145 | ~ 130 – 150 |

*Values are approximate and may vary with dimension and product form.

From a durability viewpoint:

- O temper is forgiving and highly formable, ideal for components that will see heavy forming, deep bending, or subsequent machining where residual stress must be minimized.

- H32 strikes a balance: enough strength for demanding marine service, with meaningful ductility to absorb localized overloading without catastrophic failure.

- H34 offers higher strength but slightly reduced elongation, better suited for compact components and higher-stress hardware where stiffness matters more than extreme formability.

The unchanging modulus of elasticity across tempers is also key. No matter the hardening, deflection behavior under load remains predictable, simplifying structural analysis and cross-section optimization.

Implementation Standards: Hidden Guarantees Behind Every Bar

In the marine sector, 5052 aluminum solid bar is not just “5052”—it is 5052 as defined by rigorously controlled standards. This is where compliance morphs into reliability.

Common standards and specifications associated with 5052 solid bar include:

- ASTM B211 for aluminum and aluminum-alloy bars and rods sets requirements for chemical composition, tensile properties, dimensional tolerances, and surface quality.

- EN/ISO standards (such as EN 573 for chemical composition and EN 485/515 for mechanical properties and temper designations) govern European supply.

- Marine-specific classification societies such as ABS, DNV, LR, CCS, and others may issue approvals or requirements for certain aluminum products used in critical structural or safety-related marine applications.

For marine component designers, these standards provide:

- Confidence that a 5052-H32 bar from different batches or mills will perform within a narrow property envelope.

- Traceability through mill certificates that list chemical composition, mechanical test results, heat number, and temper verification.

- A technical basis for satisfying regulatory requirements and ship classification audits.

When sourcing 5052 Marine grade aluminum solid bar, checking the alignment with relevant standards is essentially checking the reliability of your stress calculations and your safety margins.

Alloy Tempering as a Design Variable, Not Just a Label

In practice, the temper of 5052 solid bar is an active design choice that shapes how a component behaves through its entire life cycle—from machining to installation to decades of service.

From a distinctive viewpoint, you can think of temper as a “pre-programmed stress history” built into the metal:

- In O temper, internal stresses are largely relaxed. This is advantageous for precision-machined components where dimensional stability is critical, especially for mating surfaces and threaded features.

- In H32 and H34 tempers, the material has accumulated cold work, increasing dislocation density. This “stored” strain energy boosts yield and tensile strengths, which improves resistance to permanent deformation under load.

For marine hardware:

- High-precision parts such as bearing housings, custom bushings, or manifold blocks may be machined from 5052-O and, in some cases, further conditioned after machining.

- General structural and fastening components like cleat bases, brackets, and hinge arms often use 5052-H32 or 5052-H34 to achieve a better strength-to-weight ratio while still allowing reliable bending, drilling, or threading.

A thoughtful temper selection avoids two major durability risks: cracking from over-hardened, low-ductility metal, and plastic deformation from over-soft, under-strength stock.

Corrosion Resistance: How 5052 Fights the Sea’s Slow Attack

Saltwater corrosion is nuanced. It is not just about whether a metal rusts; it is about where, how fast, and under what conditions. 5052’s marine-grade reputation is anchored in several specific resistances:

- General corrosion: 5052 develops a stable, adherent oxide film in marine atmospheres. Compared with many other aluminum alloys, its rate of uniform corrosion in seawater is relatively low.

- Pitting and crevice corrosion: Thanks to its Mg content and low Cu, 5052 exhibits good resistance to localized corrosion, especially when surfaces are cleaned and drainage is designed correctly.

- Stress corrosion cracking: For non-heat-treatable Al-Mg alloys like 5052, susceptibility is lower than that of many high-strength, heat-treatable aluminums. Proper design to avoid sharp notches and residual tensile stress further enhances this advantage.

- Galvanic corrosion: When used with stainless steel fasteners or in contact with more noble alloys, galvanic couples can occur. However, in many practical assemblies, correct isolation washers, sealants, and coating strategies allow 5052 to co-exist effectively with mixed materials.

This corrosion behavior makes 5052 solid bar especially trusted for components that cannot be easily inspected or replaced, such as hidden fastener bosses, backing plates behind deck hardware, underwater or splash-zone fittings, and bracing elements inside enclosed spaces.

A Different Way to View Machinability and Fabrication

For engineers and builders, 5052’s “medium” machinability is not a drawback—it is a hint about how to approach the material. Compared with free-machining alloys, 5052 is slightly gummier and tends to form continuous chips. But its combination of machinability, weldability, and formability is hard to beat in marine settings.

Distinctive fabrication perspectives include:

- Welding behavior: 5052 welds readily using common processes like MIG and TIG, with good weld strength and corrosion performance, especially when compatible filler alloys are used (such as 5356). For welded marine frames, housings, guards, and brackets, the post-weld strength remains acceptably high without heat treatment.

- Cold forming: Bending, rolling, and forming operations are well supported, especially in O and H32 tempers. This allows complex hardware geometry—curved guard rails, contoured brackets, and structural doublers—to be made without cracking.

- Machining: While tool selection and cutting parameters should be optimized for non-heat-treatable aluminum, 5052 machines cleanly when sharp tooling, appropriate lubrication, and correct chip evacuation are used. For solid bar, this means consistent surface finish on turned shafts, precise bores, and reliable threads for fasteners and couplings.

In real-world marine fabrication shops, this combination simplifies workflows: a single alloy can be cut, formed, welded, and machined into a family of components without constantly changing materials or post-treatments.

Thermal and Physical Behavior: Durability Across Temperature Swings

Marine environments subject materials to more than moisture; there are temperature swings, sun exposure, and occasionally cryogenic-like conditions in certain industrial marine systems.

physical properties of 5052 relevant to solid bar components include:

- Density: ~ 2.68–2.72 g/cm³, helping reduce system weight compared with steels.

- Coefficient of thermal expansion: about 23–24 × 10⁻⁶ /K, important for assemblies that combine dissimilar materials, such as aluminum housings with stainless shafts or inserts.

- Thermal conductivity: relatively high, which helps spread localized heat from friction, bearings, or sunlight, reducing thermal hot spots that might otherwise drive localized expansion, distortion, or coating degradation.

From a durability mindset, these properties allow designers to anticipate joint movement, thermal stress, and alignment changes. Over long vessel life, microscopic mismatches in thermal expansion can translate into macroscopic issues such as gasket leaks or misaligned linkages. Incorporating 5052’s expansion and conductivity into the design reduces such risks.

5052 Solid Bar Across the Vessel: Where It Quietly Works

A walk through a modern vessel—whether a patrol craft, workboat, yacht, or offshore platform support vessel—reveals dozens of silent roles for 5052 Marine grade aluminum solid bar:

- Deck and topside brackets for antennas, radar units, and navigation lights

- Reinforcement bosses around hatch hinges and latches

- Steering system and linkage components where moderate strength and corrosion resistance are crucial

- Custom cleats, tie-down anchors, and rope guides

- Pump stands, motor mounts, and compressor brackets in machinery spaces

- Railing posts, stanchion bases, and safety gate hardware

In each case, the designer has quietly weighed alternatives—steels that need coatings and add weight, other aluminum alloys that may be stronger but less corrosion-resistant—and concluded that over years of salt, impact, vibration, and maintenance cycles, 5052 is more likely to “age gracefully.”

Design Insight: Using 5052’s Properties to Prevent Failure, Not Just Meet Specs

The most distinctive way to think about 5052 Marine grade aluminum solid bar is to see it as a failure-avoidance material.

Instead of asking whether it meets a minimum tensile strength, consider design choices like:

- Selecting H32 over H34 for a component expected to experience dynamic impacts, trading a little strength for extra ductility to prevent brittle-like cracking in accidental overload situations.

- Choosing 5052 for concealed structural supports where direct inspection is difficult, prioritizing corrosion resistance and ductility over maximum static strength.

- Taking advantage of its excellent weldability to design modular components that can be repaired or extended in service, rather than replaced entirely.

- Relying on its predictable work-hardening behavior to refine forming operations and avoid microcracking at bends, especially for parts that will be cyclically loaded.

This mindset views the material’s datasheet as a map of how it will behave if something goes wrong—not just how it behaves in a perfect, static test.

Related Products

Marine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsRelated Blog

5052 Marine Aluminum Hexagonal Bars for High Durability Marine Parts

5052 marine aluminum hexagonal bars combine strong corrosion resistance, good strength-to-weight ratio, and excellent workability in a geometry that’s ideal for precision marine components.

View Details5052 Marine Aluminum Bar for Coastal Marine Engineering Projects

The 5052 marine aluminum bar is a premium product dedicated to the scrupulous requirements of coastal marine engineering projects. It stands out due to its excellent corrosion resistance, weldability, and formability.

View Details5052 Marine Aluminum Hollow Bars for Saltwater Proof Marine Frames

When it comes to the maritime industry, choosing the right materials for constructing robust marine frames is imperative. Among various alloys, 5052 marine aluminum hollow bars have made a significant mark due to their superior properties.

View Details5052 Marine Grade Aluminum Solid Bar for Lightweight Offshore Components

As the maritime industry continues to evolve toward efficiency and performance optimization, the choice of materials plays a pivotal role in determining the success of marine designs.

View Details5083 5052 H32 60mm aluminum bar for boat

High-performance 5083 and 5052 H32 60mm aluminum bars tailored for marine applications. Ideal for boat building with excellent corrosion resistance, superior strength, and formability.

View Details5052 Marine Grade Aluminum Solid Bar for Saltwater Tolerant Boat Parts

High-performance 5052 marine grade aluminum solid bar, engineered for superior corrosion resistance and durability in saltwater environments. Ideal for boat parts and marine applications demanding long-lasting strength and reliability.

View Details

Leave a Message