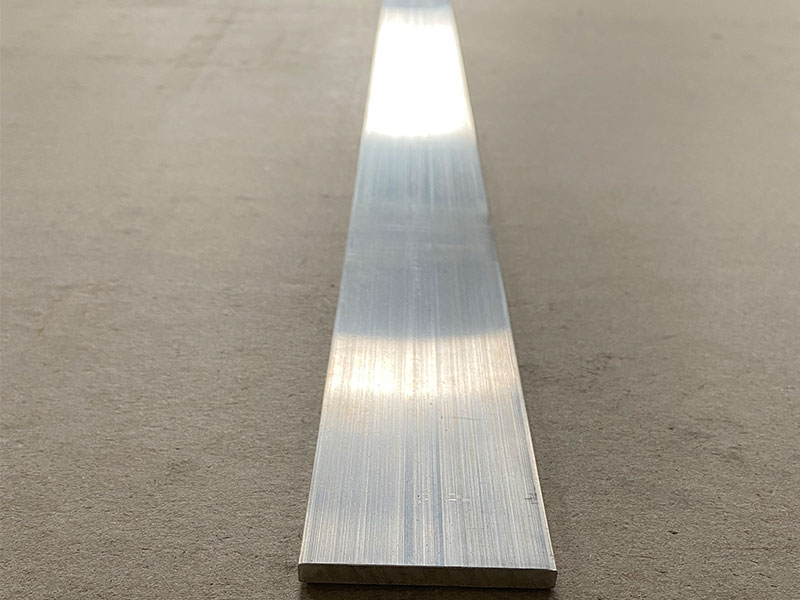

5052 Marine Aluminum Hexagonal Bars for High Durability Marine Parts

5052 Marine aluminum hexagonal bars combine strong corrosion resistance, good strength-to-weight ratio, and excellent workability in a geometry that’s ideal for precision marine components. Their hexagonal profile makes them easy to machine into fasteners, connectors, and structural fittings that must hold tight tolerances and survive harsh saltwater environments.

5052 is a non-heat-treatable aluminum–magnesium alloy known for its outstanding resistance to seawater and industrial atmospheres. When produced as hexagonal bars, it becomes an excellent stock material for:

- Marine fasteners and fittings

- Shaft collars and couplings

- Small structural nodes and brackets

- Precision machined parts exposed to salt spray

The hex profile provides multiple flat faces for easy clamping, wrenching, and indexing in machining operations, while the 5052 alloy itself delivers dependable durability and formability.

Chemical Composition of 5052 Aluminum

5052 is an Al–Mg alloy with magnesium as the primary strengthening element and carefully controlled minor elements to balance strength, corrosion resistance, and workability.

| Element | Typical Content (% by weight) | Notes |

|---|---|---|

| Aluminum (Al) | Balance | Base element |

| Magnesium (Mg) | 2.2 – 2.8 | Main strengthening element, improves seawater resistance |

| Chromium (Cr) | 0.15 – 0.35 | Enhances corrosion resistance and grain structure |

| Iron (Fe) | ≤ 0.40 | Impurity control for good toughness |

| Silicon (Si) | ≤ 0.25 | Controlled to maintain formability |

| Copper (Cu) | ≤ 0.10 | Kept very low to maximize corrosion resistance |

| Manganese (Mn) | ≤ 0.10 | Minor strengthening and grain refinement |

| Zinc (Zn) | ≤ 0.10 | Impurity control |

| Others (each) | ≤ 0.05 | Trace elements |

| Others (total) | ≤ 0.15 | — |

The low copper content and balanced Mg–Cr levels are reasons why 5052 performs so well in marine and salt-laden atmospheres.

Mechanical Properties & Technical Specifications

Typical mechanical properties for 5052 hexagonal bars depend on temper. For marine parts, common tempers are H32 (strain hardened, stabilized) and H34 (slightly higher strength).

| Property | 5052-H32 (Typical) | 5052-H34 (Typical) | Test Standard / Notes |

|---|---|---|---|

| Tensile Strength, Rm (MPa) | 215 – 265 | 235 – 285 | ASTM B211 / JIS / EN equivalents |

| Yield Strength, Rp0.2 (MPa) | ≥ 130 | ≥ 160 | 0.2% offset |

| Elongation (A50, %) | 7 – 12 | 6 – 10 | Depends on size and orientation |

| Brinell Hardness (HBW) | ~ 60 – 70 | ~ 65 – 75 | Approximate range |

| Density (g/cm³) | 2.68 | 2.68 | Nearly constant across tempers |

| Modulus of Elasticity (GPa) | ~ 70 | ~ 70 | Typical for Al–Mg alloys |

| Poisson’s Ratio | ~ 0.33 | ~ 0.33 | — |

| Coefficient of Thermal Expansion | ~ 23.8 × 10⁻⁶ /K | ~ 23.8 × 10⁻⁶ /K | 20–100 °C range |

| Electrical Conductivity (% IACS) | ~ 32 – 36 | ~ 32 – 36 | Approximate, alloy-dependent |

| Thermal Conductivity (W/m·K) | ~ 138 | ~ 138 | At room temperature |

These values make 5052 suitable for medium-load marine components where corrosion resistance and moderate strength are more important than ultra-high structural strength.

Geometric & Dimensional Information for Hex Bars

5052 marine hex bars are supplied in a range of across-flats sizes, lengths, and tolerances suitable for both machining and direct-use applications.

| Parameter | Typical Range / Options | Notes |

|---|---|---|

| Across Flats (AF) Size | 6 – 80 mm (approx. 1/4" – 3") | Custom sizes available on request |

| Standard Lengths | 3000 mm, 4000 mm, 6000 mm | Cut-to-length service commonly available |

| Length Tolerance | ± 5 – 10 mm (standard) | Tighter on request |

| AF Dimensional Tolerance | h11, h12 (typical) | According to ISO or ASTM dimensional specs |

| Corner Radius | Sharp to small controlled radius | Depends on production route (extruded/drawn) |

| Straightness | ≤ 1–2 mm per meter | Suitable for high-precision machining |

| Surface Condition | Mill finish / brushed / anodized | Marine-grade anodizing available |

The hex geometry offers multiple flat faces for wrenching and positioning, making it particularly useful for bolts, nuts, and mechanical couplings in marine environments.

Features for Marine Use

Marine-Grade Corrosion Resistance

5052 aluminum is widely recognized as a true marine-grade alloy. Its combination of magnesium and chromium, along with very low copper, provides:

| Environment / Medium | Corrosion Performance |

|---|---|

| Seawater immersion | Excellent, long service life with minimal pitting |

| Salt spray / coastal air | Excellent resistance, even uncoated |

| Industrial atmosphere | Very good, resistant to many pollutants |

| Freshwater | Excellent |

| Neutral or mildly alkaline pH | Very good stability |

For additional protection, many users specify anodizing or marine-grade coatings. The naturally forming aluminum oxide film already offers good base-level protection, which coatings can further enhance.

High Strength-to-Weight Ratio

Compared with steel:

| Material | Density (g/cm³) | Relative Weight (at equal volume) | General Comment |

|---|---|---|---|

| 5052 Aluminum | ~ 2.68 | ~ 1/3 of carbon steel | Much lighter for same volume |

| Carbon Steel | ~ 7.85 | Reference | Heavier but higher strength |

| Stainless Steel | ~ 7.9 – 8.1 | Slightly heavier than carbon steel | High corrosion resistance, higher weight |

For many marine parts—especially those above the waterline or in moving systems—reducing weight lowers fuel consumption, eases installation, and reduces load on supporting structures.

Excellent Workability & Fabrication

5052 hex bars machine easily on conventional and CNC equipment:

| Process | Suitability for 5052 Hex Bars | Notes |

|---|---|---|

| CNC Turning | Very good | Hex profile allows easy clamping/indexing |

| Milling / Drilling | Very good | Clean chip formation with appropriate tooling |

| Sawing / Cutting | Excellent | High throughput with carbide blades |

| Bending / Forming | Good in non-hardened tempers | Limited for heavily strain-hardened material |

| Welding (MIG/TIG) | Excellent | Common filler alloys: 5356, 5183 |

For welded marine fabrications, 5052 offers good joint strength and toughness, particularly when using compatible Al–Mg welding wires.

Typical Marine Applications

Thanks to its corrosion resistance, machinability, and hex profile, 5052 Marine aluminum hexagonal bars show up in many marine system components.

| Application Area | Typical Parts Made from 5052 Hex Bars | Why 5052 Hex is Used |

|---|---|---|

| Deck Hardware & Fittings | Stand-offs, cleat brackets, spacer blocks | Saltwater resistance, light weight, easy machining |

| Fastening Systems | Custom nuts, bolts, sleeves, collars | Hex shape ideal for wrenching and anti-rotation |

| Hull & Superstructure | Connection blocks, small structural nodes | Moderate strength with corrosion resistance |

| Railings & Safety Gear | Coupling joints, hinge elements, tensioning components | Attractive finish, low maintenance |

| Propulsion & Drive Systems | Shaft collars, spacers, ancillary brackets | Stable under vibration and cyclic loading |

| Electrical & Control Gear | Mounting posts, busbar supports, instrument brackets | Good conductivity, corrosion resistance, machinability |

| Offshore & Port Equipment | Cable clamps, guide blocks, adjustable fittings | Robust in spray zones and splash regions |

In many of these applications, 5052 hex bars replace heavier stainless steel components where ultra-high strength is not required, but weight, cost, and corrosion performance are critical.

Comparison with Other Marine Aluminum Alloys

For marine designers and buyers, it helps to understand where 5052 stands relative to other common alloys.

| Property / Aspect | 5052 | 5083 | 6061 |

|---|---|---|---|

| Primary Alloying Element | Mg | Mg | Mg + Si |

| Strength Level | Medium | High | Medium–high (heat treatable) |

| Corrosion in Seawater | Excellent | Excellent (often superior) | Good, but slightly less than 5xxx |

| Weldability | Excellent | Very good | Very good, but heat-affected strength loss |

| Typical Use Focus | Sheet/plate, bars, general marine parts | High-load hulls, pressure vessels | Structural frames, masts, fittings |

| Cost / Availability | Widely available, economical | Higher alloy cost, heavier sections | Very common, especially in structural extrusions |

5052 hex bars hit a sweet spot for many small-to-medium marine parts where:

- Corrosion resistance must be reliably high

- Strength demands are moderate

- Machining and fabrication speed are important

- Weight savings versus steel are desired

Surface Finishes and Protective Options

To tailor 5052 hex bars to specific marine environments, different surface treatments may be applied.

| Finish / Treatment | Appearance | Benefit in Marine Environments |

|---|---|---|

| Mill Finish | As-extruded, matte/bright | Cost-effective, sufficient for many internal parts |

| Mechanical Brushing | Uniform satin | Improved aesthetics, better coating adhesion |

| Anodizing (Clear) | Silver, slightly glossy | Increased hardness, improved corrosion resistance |

| Anodizing (Colored) | Black, bronze, etc. | Both functional and decorative, UV-stable |

| Powder Coating | Wide color range | Extra barrier layer, abrasion and UV protection |

| Polishing | High gloss | Decorative fittings, premium deck hardware |

For exposed marine hardware, anodizing or powder coating over properly prepared 5052 surfaces delivers long-term protection with minimal maintenance.

5052 Marine aluminum hexagonal bars offer a practical balance of corrosion resistance, moderate strength, and efficient machinability in a geometry that is ideal for marine fasteners, joints, and precision fittings. Their advantages can be captured succinctly:

| Advantage | Value for Marine Users |

|---|---|

| Outstanding seawater resistance | Long service life, reduced replacement frequency |

| Hexagonal geometry | Easy wrenching, anti-rotation, precise indexing |

| Lightweight vs. steel | Lower vessel weight, easier handling and installation |

| Excellent weldability | Compatible with common marine welding procedures |

| Good machinability | Fast production, clean finish, tight tolerances |

| Versatile surface treatments | Adaptable to aesthetic and durability requirements |

For designers, boat builders, and marine equipment manufacturers aiming to improve durability while reducing weight and maintenance, 5052 Marine aluminum hexagonal bars are a robust, cost-efficient material choice.

Related Products

Marine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsRelated Blog

5052 Marine Aluminum Hollow Bars for Offshore Engineering Solutions

In the domain of offshore engineering, material selection is critical to ensure the resilience, functionality, and longevity of maritime structures. Among various alloys.

View Details5052 Marine Grade Aluminum Solid Bar for Saltwater Tolerant Boat Parts

High-performance 5052 marine grade aluminum solid bar, engineered for superior corrosion resistance and durability in saltwater environments. Ideal for boat parts and marine applications demanding long-lasting strength and reliability.

View Details5052 Marine Aluminum Bar for Coastal Marine Engineering Projects

The 5052 marine aluminum bar is a premium product dedicated to the scrupulous requirements of coastal marine engineering projects. It stands out due to its excellent corrosion resistance, weldability, and formability.

View Details5052 Marine Grade Aluminum Solid Bar for Saltwater Proof Marine Structures

Superior corrosion resistance and mechanical properties of 5052 Marine Grade Aluminum Solid Bar, engineered for durable and reliable saltwater-proof marine structures. Learn about its chemical composition, alloy tempering, implementation standards, and ke

View Details5052 Marine Aluminum Hexagonal Bars for Marine Hull Strengthening Parts

5052 marine aluminum hexagonal bars are a dedicated structural material for high‑strength, corrosion‑resistant hull reinforcement and outfitting in marine environments.

View Details5052 Marine Grade Aluminum Solid Bar for Lightweight Offshore Components

As the maritime industry continues to evolve toward efficiency and performance optimization, the choice of materials plays a pivotal role in determining the success of marine designs.

View Details

Leave a Message