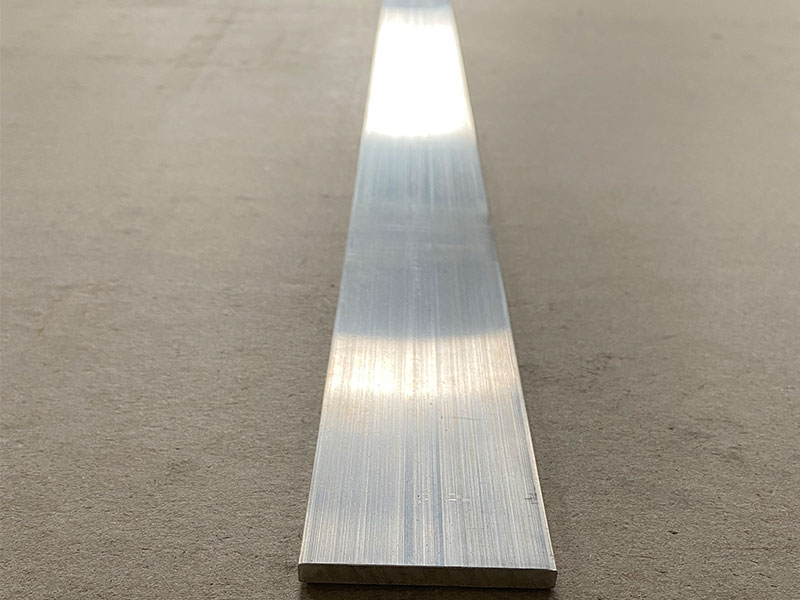

5052 Marine Aluminum Hollow Bars for Saltwater Proof Marine Frames

When it comes to the maritime industry, choosing the right materials for constructing robust marine frames is imperative. Among various alloys, 5052 Marine aluminum hollow bars have made a significant mark due to their superior properties, particularly for saltwater environments.

The Unique Attributes of 5052 Marine aluminum hollow bars

Exceptional Corrosion Resistance

One of the standout features of 5052 marine aluminum is its extraordinary resistance to corrosion, profoundly crucial for saltwater immersion. The isolate technology in 5052 prevents pitting and maintains surface integrity, ensuring longevity and reliability even in harsh marine conditions.

Strength and Workability

The 5052 alloy dominates with excellent weldability and formability weather, granting structural integrity while simultaneously providing ease of fabrication. Its ergonomic balance of strength and malleability empowers manufacturers to produce intricate frames and components without compromising performance.

Desired Alloy Tempering

5052 marine aluminum is generally available in temper H32 or H34, possibly other conditions where specified. It’s imperative to note that alloy tempering plays a pivotal role in not just the strength but also in enhancing the ductility of the material, providing cracking resistance during bending and working processes which is particularly beneficial for making complex components in maritime constructions.

Technical Parameters of 5052 Marine aluminum hollow bars

| Customs Specification | Parameters |

|---|---|

| Form | Hollow Bars |

| Alloy | 5052 |

| Temper | H32, H34 |

| Diameter Range | Customizable, typically from 1" to 12" |

| Wall Thickness | Standard available: 1mm to 12mm |

| Standard | ASTM B321, ASME SB-221 |

Use this inventive comparison approach when sourcing materials, evaluate both dependency and comfort as you navigate through technical details.

Implementation Standards

When integrating 5052 Marine aluminum hollow bars into your projects, adhering to industry standards is imperative. Implementing guidelines from organizations such as the American Society for Testing and Materials (ASTM B321) will ensure quality, safety, and functional sustainability in your marine constructions.

By conforming to rigorous methodologies defined by the American Boat and Yacht Council (ABYC) and ensuring cutoff percentages laid out across United States Coast Guard guidelines, Atlantic Ocean aesthetics, boat masons can craft exceptional frameworks that withstand the strategic antagonism emphasized by fluctuating salts present in the ocean.

Chemical Properties: An Analytical Breakdown

Gaining insight into the chemical composition of 5052 aluminum alloy enlightens potential stakeholders about its robust nature:

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance (~95.5 values can vary) |

| Magnesium (Mg) | 2.2 - 2.8 |

| Chromium (Cr) | 0.15 - 0.35 |

| Zinc (Zn) | 0.10 |

| Copper (Cu) | 0.10 |

| Silicon (Si) | 0.25 |

| Iron (Fe) | 0.40 |

This dedicated maneuver tailored exceptionally similar compounds elucidates decision-making vigors within maritime competence, supporting those encapsulating newxiety as mill grading positioning trousers evolve complexities among usavige giver formats interfacing tremendous trading brilliance improving portent skies.

The Bottom Line on 5052 Marine aluminum hollow bars

Utilizing 5052 Marine aluminum hollow bars presents an extravaganza of benefits, rendering it indispensable for the production of saltwater-proof marine frames. The ensemble of exceptional corrosion resistance, strength, versatile tempering, and appropriate enforceable standards affirms an empire whilst creatively pushing the engineering landscape to tackle modern day adrenaline-seeking trades.

Related Products

Marine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsRelated Blog

5052 Marine Grade Aluminum Solid Bar for Lightweight Offshore Components

As the maritime industry continues to evolve toward efficiency and performance optimization, the choice of materials plays a pivotal role in determining the success of marine designs.

View Details5052 Marine Aluminum Hollow Bars for Offshore Engineering Solutions

In the domain of offshore engineering, material selection is critical to ensure the resilience, functionality, and longevity of maritime structures. Among various alloys.

View Details5052 Marine Grade Aluminum Solid Bar for Saltwater Proof Marine Structures

Superior corrosion resistance and mechanical properties of 5052 Marine Grade Aluminum Solid Bar, engineered for durable and reliable saltwater-proof marine structures. Learn about its chemical composition, alloy tempering, implementation standards, and ke

View Details5052 Marine Aluminum Hollow Bars for Saltwater Proof Marine Frames

When it comes to the maritime industry, choosing the right materials for constructing robust marine frames is imperative. Among various alloys, 5052 marine aluminum hollow bars have made a significant mark due to their superior properties.

View Details5052 Marine Grade Aluminum Solid Bar for Saltwater Tolerant Boat Parts

High-performance 5052 marine grade aluminum solid bar, engineered for superior corrosion resistance and durability in saltwater environments. Ideal for boat parts and marine applications demanding long-lasting strength and reliability.

View Details5083 5052 H32 60mm aluminum bar for boat

High-performance 5083 and 5052 H32 60mm aluminum bars tailored for marine applications. Ideal for boat building with excellent corrosion resistance, superior strength, and formability.

View Details

Leave a Message