5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Frame Reinforcements

When it comes to offshore vessel deck frame reinforcements, the choice of materials is critical for durability, strength, and corrosion resistance. Among the myriad of options, 5083 marine aluminum customized shapes is know as the optimal solution for challenging marine environments.

Why 5083 Marine Aluminum for Offshore Vessel Deck Frames?

5083 aluminum alloy, renowned for its exceptional corrosion resistance in saltwater, combines lightweight properties with excellent mechanical strength—a perfect fit for deck frame reinforcements. Unlike traditional structural steel prone to rust, 5083 marine aluminum resists pitting and crevice corrosion, even under continuous exposure to seawater.

Customized shapes of 5083 aluminum ensure precision-fit components tailored to complex offshore deck structures, such as brackets, stiffeners, girder segments, and specialized reinforcement sections. This custom fabrication capability enhances structural integrity while meeting strict dimensional tolerances.

Technical Parameters and Implementation Standards

Achieving the mechanical properties and durability for offshore vessel applications requires adherence to strict parameters defined under marine standards.

| Parameter | 5083 Aluminum Alloy |

|---|---|

| Alloy Series | 5xxx (Al-Mg) series |

| Temper designation | H111, H112, H116, H321 (common marine tempers) |

| Density | 2.66 g/cm³ |

| Yield Strength (σ₀.₂) | 215 – 310 MPa (depends on temper) |

| Tensile Strength (σᵤ) | 275 – 350 MPa |

| Elongation (%) | 12 – 22% |

| Hardness (Brinell) | 75 – 95 HB |

| Corrosion Resistance | Excellent against seawater and salt spray |

| toughness | Highly resistant, good weldability |

Implementation Standards include:

- ABS (American Bureau of Shipping) Rules for Materials

- DNV GL OS-C101 for offshore structural aluminum alloys

- ISO 9227 for salt spray corrosion testing

- ASTM B209 for aluminum sheet and plate specifications

For offshore reinforcement shapes, compliance with ABS Grade ABSYH or Lloyd’s Register Marine Vessel materials standards ensures structural safety longevity and regulatory acceptance.

Distinct Alloy Tempering and Conditioning for Marine Durability

Tempering affects both the mechanical strength and corrosion-resistance crucial in harsh offshore environments. For 5083 marine aluminum shapes, the commonly used alloys tempers include:

- H116/H321 – Stabilized tempers obtained by strain hardening followed by specific heat treatments that resist stress corrosion cracking (SCC).

- H111/H112 – Non-heat-treated alloys union with lower tempers, providing higher ductility crucial for complex forming.

- H116 temper is preferred for its improved resistance against exfoliation corrosion—a common problem in marine structures.

Conditioning processes may include pre-aging and stress-relieving to eliminate residual stresses from manufacturing and ensure water-tight sealing when integrated into offshore vessel deck frames.

Chemical Composition: Precision Formulation for Versatility and Strength

5083 alloy's chemical composition is meticulously fine-tuned to balance the characteristics vital to offshore performance—combining strength, toughness, anodizability, and natural protection.

| Element | Percentage (wt%) |

|---|---|

| Aluminum (Al) | Balance (~94.9 – 96.8%) |

| Magnesium (Mg) | 4.0 – 4.9 % |

| Manganese (Mn) | 0.4 – 1.0 % |

| Chromium (Cr) | 0.05 – 0.25 % |

| Iron (Fe) | ≤ 0.4 % |

| Silicon (Si) | ≤ 0.4 % |

| Copper (Cu) | ≤ 0.1 % |

| Zinc (Zn) | ≤ 0.25 % |

| Titanium (Ti) | ≤ 0.15 % |

Magnesium provides the alloy with its excellent strength and corrosion resistance. Cr and Mn ensure resistance to recrystallization during hot processes, retaining stable mechanical properties, important for welded deck structures.

Implementation Insights: Fabricating with 5083 Customized Shapes for Deck Frames

Forming & Welding: 5083 aluminum declines in potential weld hardness loss under heat inputs, an extremely valuable characteristic for structural welding associated with offshore deck frames. Customized shape fabrication involves CNC cutting, press forming, extrusion bending, or roll forming—all while maintaining material integrity polymerized by 5083's temper and dimensional accuracy algorithms.

Quality Control & Corrosion Testing: Stringent non-destructive testing (NDT)—ultrasonic and eddy current – combined with salt spray tests (per ISO 9227) affirm corrosion-resilience and mechanical correctness.

Maintenance Considerations: The protective oxide marquee naturally generated on 5083 aluminum surfaces reduces lifecycle costs and maintenance frequency for intense new wave impact zones.

Related Products

Marine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

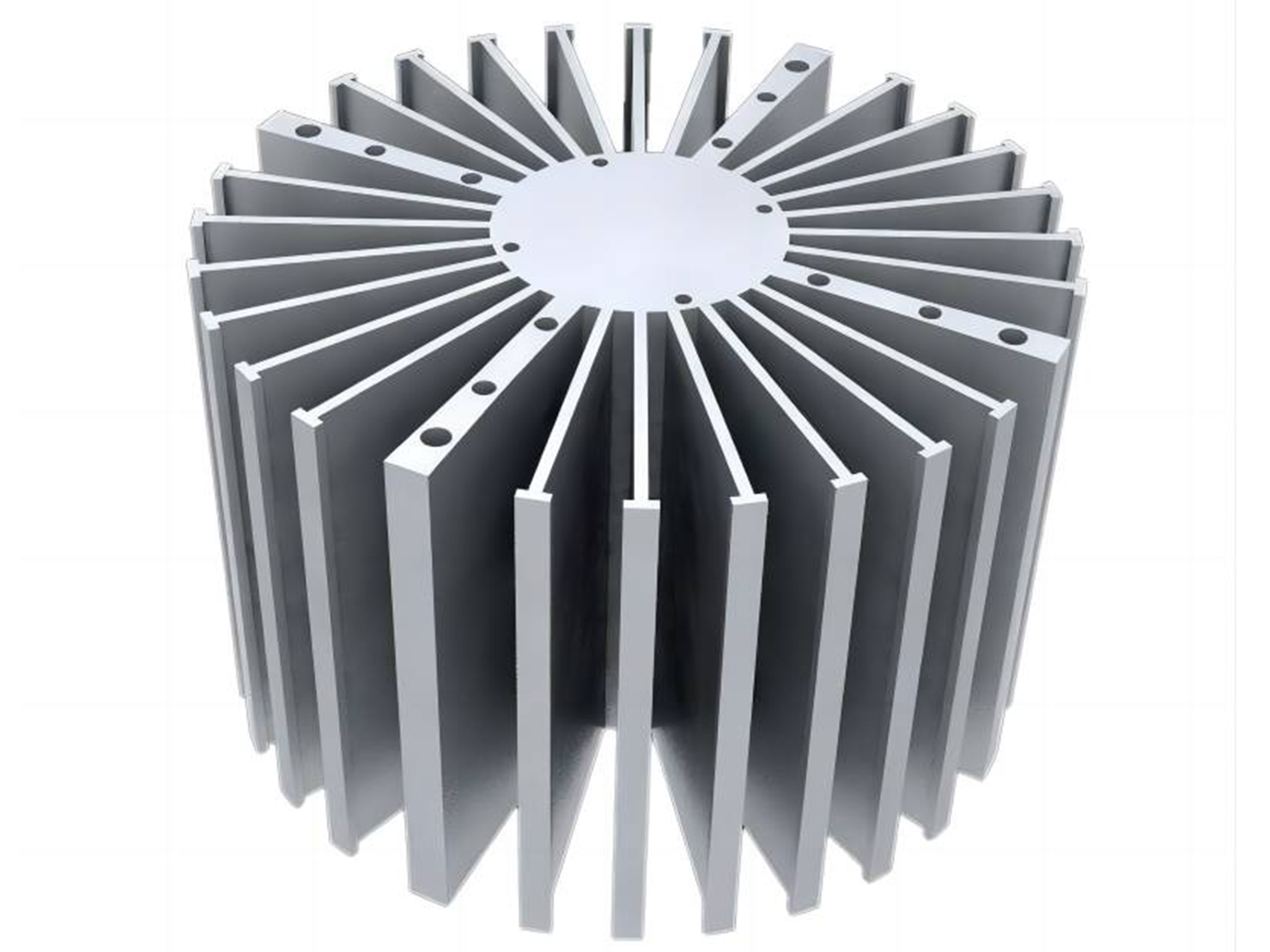

View DetailsMarine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsRelated Blog

5083 Marine Aluminum Customized Shapes for Saltwater Resistant Boat Deck Frames

When it comes to boat deck frames that endure the relentless challenge of saltwater environments, the choice of materials is paramount. Among all options.

View DetailsMarine Aluminum Fencing and Railings for Durable Boat Deck Guardrails

OverviewMarine aluminum fencing and railings are purpose-designed alloy systems used for guardrails, handrails, stanchions, and safety barriers on boats, docks, marinas, and waterfront properties.

View Details5083 Marine Aluminum Fencing and Railings for Custom Coastal Guardrails

5083 marine aluminum is a widely used alloy for coastal guardrails, fencing, and railings because it combines excellent corrosion resistance in seawater environments, strong mechanical properties, and good weldability.

View Details5083 Marine Aluminum Fencing and Railings for Coastal Marine Safety Solutions

When it comes to enhancing safety and durability along coastal infrastructure, selecting the right materials for fencing and railings is paramount. Among the most trusted choices is 5083 marine aluminum.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability.

View Details5083 Marine Aluminum Customized Shapes for Coastal Infrastructure Design and Build

When it comes to the demanding environments of coastal infrastructure design and build, 5083 Marine Aluminum continues to solidify its leadership with exceptional strength and corrosion resistance.

View Details

Leave a Message