6061 Marine Aluminum Hexagonal Bars for Lightweight Marine Frame Construction

In the ever-evolving marine industry, choosing the correct material for frame construction is a critical factor influencing performance, durability, and safety. Among these materials, 6061 Marine Aluminum hexagonal bars have gained widespread appreciation due to their outstanding mechanical properties, corrosion resistance, and flexibility in design.

What Makes 6061 Marine Aluminum Ideal for Marine Frames?

6061 aluminum is an aluminum-magnesium-silicon alloy renowned for its excellent strength-to-weight ratio, corrosion resistance, and good workability. When fabricated into hexagonal bars, this alloy provides distinct structural advantages:

We use a lot of 6061 marine aluminum hexagonal bars here at the plant, and honestly, they're a dream compared to some of the other materials we've worked with. The hexagonal shape is surprisingly efficient for structural applications in marine frames – it provides excellent strength-to-weight ratio, which is crucial for boats and other marine vehicles where every ounce counts. The machining is relatively straightforward, though we've found that proper lubrication is essential to prevent tool wear, especially when dealing with larger diameter bars. The 6061 alloy itself is fantastic; its corrosion resistance is a major selling point, minimizing maintenance and extending the lifespan of the finished product. We’ve experimented with surface treatments like anodizing to further enhance corrosion resistance in particularly harsh saltwater environments, and the results have been .

One thing I've noticed that's less obvious is the impact of the bar's grain orientation on the final product's strength. It's crucial to have a good of how the material flows during extrusion to optimize the frame design and prevent stress concentrations. We've tweaked our fabrication processes based on this, ensuring the bars are oriented optimally within the frame to maximize strength in areas under heavy load, especially in joints. For example, aligning the strongest grain direction along the primary stress axes improves fatigue life considerably. It’s a subtle detail, but it speaks volumes about how much care goes into building

- Lightweight yet Robust: The hexagonal cross-section provides efficient distribution of stress and reduced weight, making it ideal for marine frame components where every kilogram saved contributes to better fuel efficiency and performance.

- Corrosion Resistance: Marine environments impose high saline corrosion risks. 6061 marine-grade aluminum features enhanced corrosion resistance, especially when properly tempered and anodized.

- Ease of Fabrication: The alloy’s moderate strength allows ease in machining, welding, and shaping, enabling bespoke frame designs that meet complex marine application needs.

Technical Parameters & Alloy Tempering

Typical Mechanical Properties (6061-T6 temper):

| Property | Value |

|---|---|

| Tensile Strength (Ultimate) | 290 MPa (42,000 psi) |

| Yield Strength | 240 MPa (35,000 psi) |

| Elongation at Break | 12-17% |

| Hardness (Brinell) | 95 HB |

| Density | 2.70 g/cm³ |

| Modulus of Elasticity | 69 GPa (10,000 ksi) |

- Tempering Designations: 6061 is commonly found in T6 temper (solution heat-treated and artificially aged), providing superior strength suited to load-bearing marine frames. Other tempers such as T4 and T5 can offer different balances of strength and ductility. Selecting temper impacts weldability, corrosion resistance, and stress tolerance.

Chemical Composition of 6061 Alloy

| Element | Typical Composition Range (%) |

|---|---|

| Silicon (Si) | 0.40 − 0.8 |

| Iron (Fe) | ≤ 0.7 |

| Copper (Cu) | 0.15 − 0.4 |

| Manganese (Mn) | ≤ 0.15 |

| Magnesium (Mg) | 0.8 − 1.2 |

| Chromium (Cr) | 0.04 − 0.35 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance |

The precise balance of magnesium and silicon leads to the formation of the Mg2Si phase, crucial for precipitation hardening, which enhances mechanical strength during tempering.

Implementation Standards and Certification

To ensure quality and safety in marine applications, 6061 marine aluminum hex bars comply with multiple stringent industry and international standards:

- ASTM B429: Standard specification for aluminum-alloy extruded bars, rods, wire, profiles, and tubes, specifying tolerances, mechanical requirements, and permissible alloy compositions.

- MIL-DTL-5541 & MIL-A-8625: Define aerospace and marine surface treatment requirements such as anodizing and chemical finishes to optimize corrosion resistance.

- ISO 6362: Cold worked aluminium alloys - chemical composition and mechanical properties expert for sectors including marine construction.

Practical Applications in Marine Frame Construction

In marine frame construction, 6061 aluminum hexagonal bars serve varied functions:

- Structural Frameworks: The bars provide strong yet lightweight support members for decks, railings, and bulkheads, improving overall vessel stability.

- Rigging Fittings: The multi-angle edges of hex bars allow secure bolting and fitting integration, enhancing joint strength.

- Mount Points and Supports: Hex bars offer flat facets to bond with plates and other structural elements, ideal for engine mounts and suspension systems.

- Corrosion-resilient Assemblies: Due to enhanced chloride resistance, frames can endure saltwater penetration without premature metal degradation.

- Custom Fabrication: Their machinability enables fine detailing with precise dimensional control, pivotal for tailor-made marine frame assemblies in innovative vessel design.

| Benefit | Explanation |

|---|---|

| Weight Reduction | Hexagonal profile combined with alloy weight minimizes load without compromising sturdiness. |

| Corrosion Resistance | Superior alloy formulation with anodizing option enhances lifespan in harsh saltwater. |

| Cost-Efficiency | Precision manufacturing and extruded shape reduce material wastage and labor time. |

| High Strength-to-Ductility Ratio | Will withstand cyclic loads while maintaining critical impact resistance. |

| Design Flexibility | Crisp hexagonal shape facilitates modular joins and multi-axial stress distribution. |

Related Products

Marine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine grade aluminum solid bar

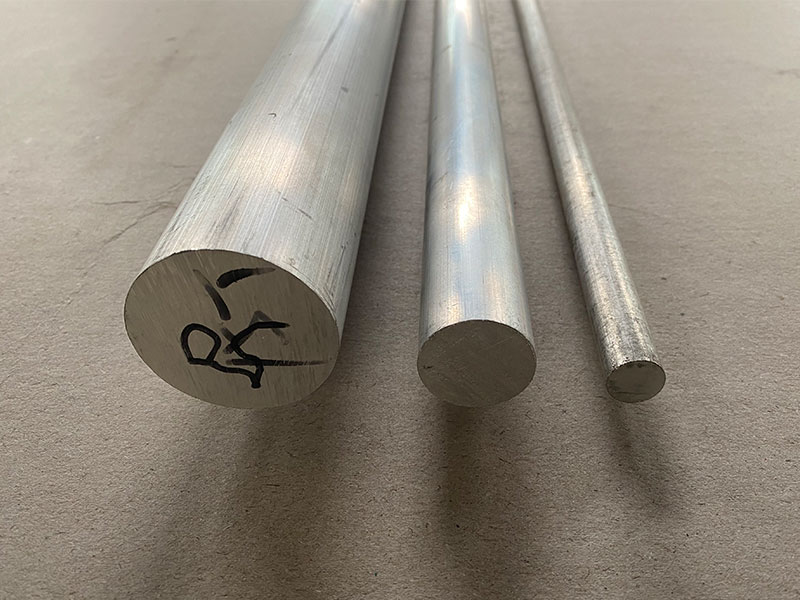

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsRelated Blog

6061 Marine Grade Aluminum Solid Bar for Boat Hull and Deck Strengthening

When it comes to constructing or reinforcing boats, durability, strength, and corrosion resistance are non-negotiable attributes. Among the available materials in marine applications.

View Details6061 Marine Aluminum Hexagonal Bars for Lightweight Marine Frame Construction

In the ever-evolving marine industry, choosing the correct material for frame construction is a critical factor influencing performance, durability, and safety. Among these materials.

View Details6061 Marine Aluminum Hexagonal Bars for Corrosion Resistant Marine Applications

6061 Marine Aluminum Hexagonal Bars for Corrosion Resistant Marine Applications: Unveiling the Technical Backbone of Modern Maritime EngineeringIn the demanding world of marine engineering.

View Details6061 Marine Grade Aluminum Solid Bar for Marine Vessel Frame Parts

The 6061 Marine Grade Aluminum Solid Bar is a premium-quality aluminum alloy widely recognized for its exceptional strength, corrosion resistance, and versatility.

View Details

Leave a Message