6061 Marine Aluminum Angles for Boat Deck Support and Reinforcement

6061 Marine Aluminum Angles are specially designed aluminum alloy structural components, widely used in marine environments for boat deck support, reinforcement, and framework. This alloy offers a superb combination of strength, corrosion resistance, and machinability, making it an ideal choice for demanding marine applications where durability and reliability are critical.

What is 6061 Aluminum Alloy?

6061 aluminum is one of the most versatile and widely used aluminum alloys. It belongs to the 6xxx series (Aluminum-Magnesium-Silicon alloy) known for their excellent strength-to-weight ratio and corrosion resistance. It is a heat-treatable alloy that can be strengthened with aging, considerable for structural components like angles, plates, sheets, and extrusions.

Chemical Composition of 6061 Aluminum Alloy

| Element | Weight Percentage (%) |

|---|---|

| Silicon (Si) | 0.40 – 0.8 |

| Iron (Fe) | 0.7 max |

| Copper (Cu) | 0.15 – 0.4 |

| Manganese (Mn) | 0.15 max |

| Magnesium (Mg) | 0.8 – 1.2 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | 0.25 max |

| Titanium (Ti) | 0.15 max |

| Aluminum (Al) | Remainder |

Features of 6061 Marine Aluminum Angles

1. Superior Corrosion Resistance

6061 alloy prides itself on excellent resistance to corrosion, especially in marine environments containing moisture, salt, and atmospheric exposure. This is essential for boat deck support members subjected to seawater and harsh coastal elements.

2. High Strength-to-Weight Ratio

These aluminum angles provide robust structural support with a lighter weight compared to steel, contributing to enhanced vessel performance by conserving weight and improving fuel efficiency.

3. Excellent Weldability

6061 Marine Aluminum provides ease of welding using TIG, MIG, or spot welding methods, permitting custom fabrication and complex assembly with strong, corrosion-resistant weld joints.

4. Good Thermal Conductivity and Machinability

This alloy allows efficient heat dissipation and easy machining into various angle sizes and profiles, complying with specific design requirements for boat decking layouts.

5. Versatile Finishing Options

6061 aluminum can be anodized or painted to boost corrosion protection further and aesthetic appeal, crucial for visible deck and railing applications.

Mechanical Properties of 6061 Aluminum Alloy (T6 Temper)

| Property | Value | Unit |

|---|---|---|

| Tensile Strength (Ultimate) | 290 – 310 | MPa (Megapascal) |

| Yield Strength (0.2% offset) | 240 – 270 | MPa |

| Elongation at Break | 10 – 12 | % |

| Hardness (Brinell) | 95 – 105 | HB |

| Modulus of Elasticity | 69 | GPa |

| Density | 2.70 | g/cm³ |

| Melting Point | 582 – 652 | °C |

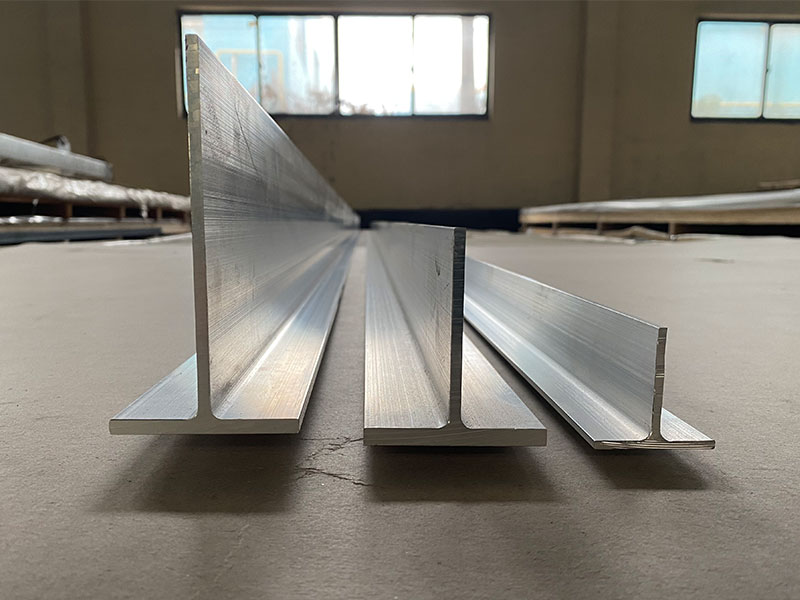

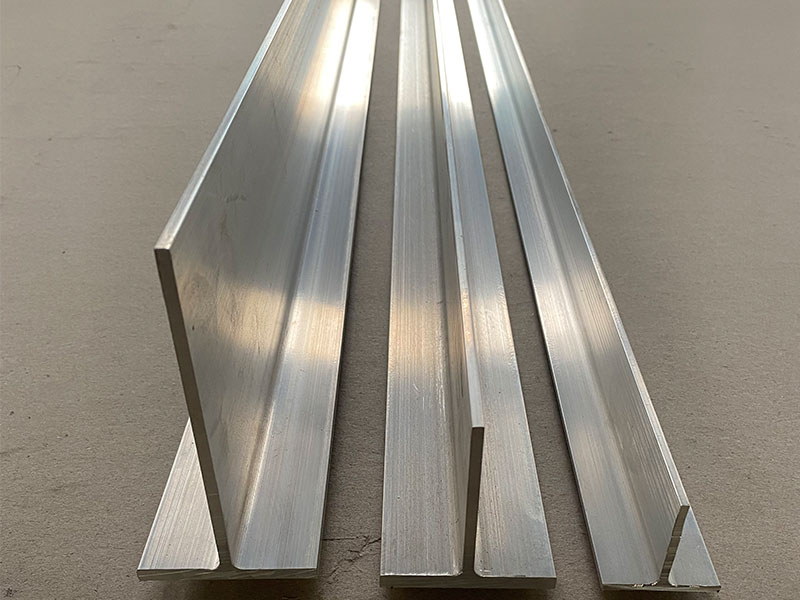

Typical Dimensions of 6061 Marine Aluminum Angles

6061 Aluminum Angles come in a wide range of sizes, shapes, and thicknesses, especially tailored for marine use cases. Common parameters include:

| Dimension (Side Length) | Thickness | Length Options |

|---|---|---|

| 20 mm to 150 mm | 3 mm to 12 mm | 1 m, 2 m, 3 m (or customized) |

Custom extrusions with varying leg sizes and thickness may be fabricated based on project specifications.

Applications in Marine Environments

6061 Marine Aluminum Angles are favored in various marine structural applications due to their optimum balance of corrosion resistance and strength.

- Boat Deck Support: Critical load-bearing frames beneath or alongside boat decks to ensure strength, support, and even weight distribution.

- Hull Reinforcement: Reinforcing sections of the hull that demand extra structural integrity without excess weight addition.

- Railings and Handrails: Custom-fabricated angles enhance safety structures on decks.

- Ladders and Steps: Offer durability in saltwater conditions and a safe support frame.

- Framing for Marine Equipment: Mounting and protecting sensitive navigation or rescue equipment ensuring erosion resistance.

- Shipyard Fabrication: Widely used for temporary and permanent structures for ship-building and repair scenarios.

Why Choose 6061 Marine Aluminum Angles?

- Combats corrosion and saline attacks typical in marine usage

- Lightweight but with structural durability

- Easy to weld and fabricate onsite reduces assembly complexity

- Supports safe and efficient marine vessel construction efforts

- Standard availability and adaptable to custom fabrication sizes

Related Products

6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsRelated Blog

6061 T6 Marine Aluminum Flat Bar for Custom Boat Deck Design

6061 aluminum is a common structural alloy known globally for its versatility. When solution heat-treated and artificially aged to the T6 temper designation, it exhibits increased strength and hardness.

View Details6061 Marine Aluminum Angles for Boat Deck Support and Reinforcement

6061 Marine Aluminum Angles are specially designed aluminum alloy structural components, widely used in marine environments for boat deck support, reinforcement, and framework.

View Details5083 5086 6061 6082 marine aluminum channel

IntroductionMarine aluminum channel is an essential structural product in shipbuilding, offshore platforms, marine fittings, and related coastal infrastructure. Compared with steel.

View Details6061 Marine Aluminum Channels for High Strength Coastal Engineering

Marine aluminum has revolutionized coastal engineering, and at the fulcrum of this evolution lies 6061 marine aluminum channels. These channels bring unparalleled strength, corrosion resistance.

View Details6061 Marine Aluminum Round Bar for Custom Marine Frame Fabrication

Marine environments are unforgiving — they demand resilience, lightweight strength, and excellent corrosion resistance from the materials we use in boat and frame fabrication.

View Details6061 Marine Aluminum Z Shaped Sections for Marine Frame Customization

In the marine industry's relentless quest for durability, corrosion resistance, and structural integrity, 6061 Marine Aluminum stands out as a premier choice—especially when customized in Z shaped sections for marine frameworks.

View Details

Leave a Message