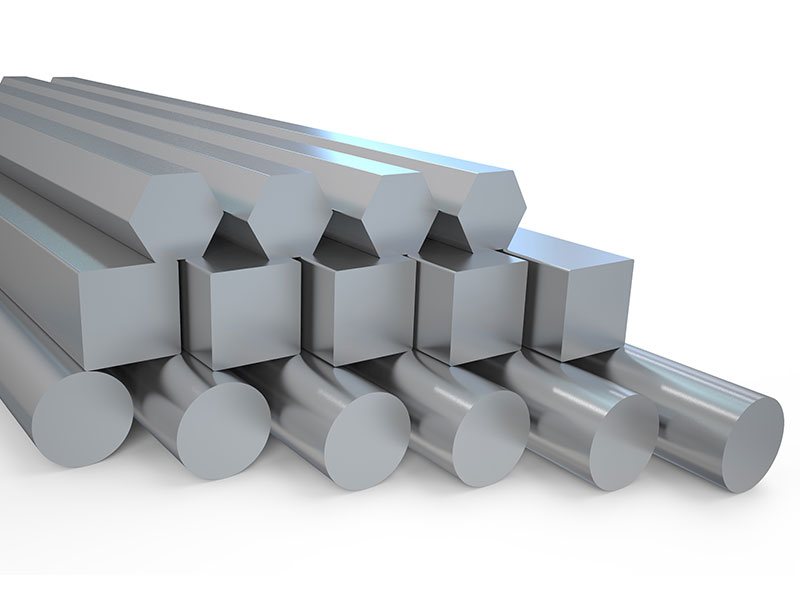

5083 Marine Aluminum Hexagonal Bars for Offshore Platform Construction

5083 Marine aluminum hexagonal bars for Offshore Platform Construction

5083 Marine aluminum hexagonal bars offer high strength, excellent corrosion resistance, and outstanding weldability for offshore platform construction. Ideal for harsh marine environments, these hex bars provide superior performance in structural frames, riser systems, deck fittings, and corrosion‑critical components.

5083 Marine aluminum hexagonal bars are engineered for demanding offshore and marine environments, including fixed and floating platforms, FPSOs, jack‑up rigs, subsea frames, and support structures. Alloy 5083 is a non‑heat‑treatable Al‑Mg alloy known for its excellent seawater corrosion resistance and good mechanical properties, especially in cold and low‑temperature conditions.

The hexagonal bar profile offers structural efficiency, accurate load distribution, and convenient machining into fittings, connectors, and high‑strength elements used throughout offshore installations.

2. Features & Advantages

2.1 Main Performance Advantages

| Feature | Description | Benefit for Offshore Platforms |

|---|---|---|

| High seawater corrosion resistance | Al‑Mg alloy with protective oxide film and controlled impurity levels | Increased service life in splash & tidal zones |

| Good medium‑to‑high strength | High Mg content and strain‑hardened tempers provide solid load‑bearing capacity | Reduced section weight vs. steel, lighter topsides |

| Excellent weldability | Compatible with common marine welding wires (e.g., 5183, 5356) and welding processes | Strong, reliable welded joints with low risk of cracking |

| Good toughness at low temperatures | Maintains ductility and impact resistance below 0 °C and in Arctic conditions | Safer operation in cold seas and cryogenic‑adjacent services |

| Outstanding corrosion fatigue behavior | Stable passivating oxide layer; good resistance to pitting and crevice corrosion | Longer inspection intervals, reduced maintenance costs |

| Lightweight vs. steel | Density ~2.66–2.70 g/cm³ (≈ 1/3 steel) | Weight savings, higher payload, easier installation |

| Non‑magnetic | Aluminum is inherently non‑magnetic | Suitable for sensor housings, subsea survey and instrumentation |

| Easily machinable | Good machinability in hard tempers; stable hex section simplifies clamping and indexing | Tight dimensional tolerances for precise fittings & couplings |

| Recyclable & sustainable | High recyclability with low recycling energy footprint | Supports ESG targets & lifecycle environmental compliance |

3. Typical Applications in Offshore Platform Construction

3.1 Structural & Load‑Bearing Components

| Application Area | Typical Use of 5083 Hex Bars |

|---|---|

| Topsides secondary structures | Brackets, stiffeners, spacer bars, and light frameworks |

| Helideck accessories | Guardrails, ladders, support ties, antenna mounts |

| Riser & umbilical supports | Clamps, hangers, support frames and locking elements |

| Deck outfitting | Handrails, racks, small foundations, cable tray supports |

| Module interfaces | Keys, connection blocks, indexing components for skid and module ties |

3.2 Corrosion‑Critical & Marine‑Splash Zone Uses

| Component Type | Specific Examples | Benefit of 5083 Hex Bars |

|---|---|---|

| Splash/tidal zone fittings | Cleats, tie‑downs, fastening blocks, splash‑zone brackets | Excellent seawater & chloride resistance |

| Mooring & fender systems | Connector blocks, energy‑dissipation elements, lock blocks | Durable, resistant to galvanic corrosion when properly isolated |

| Access systems | Hinges, axles, connection blocks for ladders, walkways & gangways | High strength at low weight |

| Cathodic protection fixtures | Mounting brackets for sacrificial anodes and ICCP hardware | Stable mechanical support with low maintenance |

3.3 Subsea & Equipment Applications

- Instrument housings and frame connectors

- ROV tool mounts and subsea guide frames (in appropriate design envelopes)

- Sensor brackets, junction box flanges, strain relief fixtures

- Non‑magnetic components in surveying and positioning systems

4. Chemical Composition of 5083 Marine Aluminum

4.1 Standard Chemical Composition (Typical Range, wt%)

| Element | Min (%) | Max (%) | Functional Role |

|---|---|---|---|

| Mg | 4.0 | 4.9 | Primary strengthener; improves seawater resistance |

| Mn | 0.40 | 1.0 | Improves strength & resistance to intergranular attack |

| Cr | 0.05 | 0.25 | Controls recrystallization; stabilizes microstructure |

| Si | — | 0.40 | Controlled impurity; high levels reduce corrosion |

| Fe | — | 0.40 | Controlled impurity; limited to control corrosion |

| Cu | — | 0.10 | Strictly limited to maximize maritime corrosion resistance |

| Zn | — | 0.25 | Limited to avoid stress‑corrosion sensitivity |

| Ti | — | 0.15 | Grain refiner |

| Others (each) | — | 0.05 | Residuals |

| Others (total) | — | 0.15 | Residuals |

| Al | Balance | Balance | Base metal |

Note: Values aligned with international standards such as EN AW‑5083 / AA5083; exact limits may vary slightly by specification (EN, ASTM, GB/T, etc.).

5. Temper Designations for Hexagonal Bars

5083 is a non‑heat‑treatable alloy strengthened by cold work (strain hardening). Common tempers offered for hexagonal bars for offshore structural service:

| Temper | Description | Typical Use |

|---|---|---|

| O | Annealed, lowest strength, highest ductility | Heavy forming, deep drawing, complex machining |

| H112 | As‑fabricated, slightly strain hardened | General structural parts, welded fitments |

| H111 | Slightly strain hardened from shaping | Components requiring forming + good toughness |

| H116 | Special marine temper; controlled cold work & properties | Plate/sheet focus but analogous bar grades by order |

| H32/H34* | Moderately strain hardened and stabilized (*) | Higher strength, machined components, where forming is minor |

*H32/H34 usage for 5083 bars depends on standard and mill practice; mechanical targets are similar across standards, but offshore approval may dictate preferred tempers (often H112/H111).

6. Mechanical Properties

6.1 Typical Mechanical Properties of 5083 Hex Bars (Reference Values)

Room‑temperature tensile properties (typical)

| Temper | Diameter Range (mm) | 0.2% Proof Stress Rp0.2 (MPa) | Tensile Strength Rm (MPa) | Elongation A50 (%) | Notes |

|---|---|---|---|---|---|

| O | ≤ 100 | ≈ 110 | ≈ 270 | 20–24 | High formability, lowest strength |

| H111 | ≤ 80 | 125–145 | 270–315 | 14–18 | Balance of strength and ductility |

| H112 | ≤ 150 | ≥ 125 | 270–320 | 12–18 | Commonly used in welded structural components |

| H32 | ≤ 80 | 215–240 | 290–330 | 10–14 | Higher strength, moderately cold‑worked |

Exact values depend on product standard, diameter, and manufacturer’s datasheet or offshore approval (e.g., DNV, ABS, LR).

7. Physical Properties

| Property | Typical Value | Relevance for Offshore Platforms |

|---|---|---|

| Density | 2.66–2.70 g/cm³ | ~1/3 the weight of steel; significant platform weight savings |

| Melting range | 570–640 °C | Important for fire scenarios & welding planning |

| Coefficient of thermal expansion (20–100 °C) | ~23.5 × 10⁻⁶ /K | Consider for mixed‑material connections and clearances |

| Thermal conductivity | 117–125 W/m·K | Good heat dissipation around welded areas and equipment |

| Electrical conductivity | 27–30 % IACS | Medium conductivity; note for earthing/grounding design |

| Modulus of elasticity (E) | ~70 GPa | Lower stiffness than steel; must be accounted for in design |

| Poisson’s ratio | ~0.33 | Structural and vibration analysis |

8. Dimensional Range & Tolerances

8.1 Typical Size Range of 5083 Hexagonal Bars

| Nominal Across‑Flats (AF) Size | Common Range | Typical Supply Lengths | Tolerance Class* |

|---|---|---|---|

| 8 – 20 mm | Precision hex stock | 3–6 m | h11 / h10 (by standard) |

| 22 – 50 mm | General structural | 3–6 m | h11 |

| 55 – 80 mm | Heavy duty fittings | 3–6 m (fixed or random) | h12 |

| 85 – 120+ mm | Large machined blocks | 3–5 m (by order) | h12 or by agreement |

*Exact tolerances depend on standard (e.g., EN 755‑3/8, ASTM B211/B221, GB/T) and contract specification.

8.2 Straightness & Surface Condition

| Parameter | Typical Requirement (Standard Class) |

|---|---|

| Straightness | ~1–2 mm/m (application and size dependent) |

| Surface finish | Mill finish, with optional shot‑blasting, machining, anodizing |

| Defects | Free from cracks, folds, heavy laps, inclusions, and corrosion |

| Edge/face quality | Uniform across flats, minimal warping; edges generally crisp |

9. Corrosion Resistance in Offshore Environments

9.1 Corrosion Behavior

| Corrosion Aspect | Performance of 5083 | Comment |

|---|---|---|

| General seawater corrosion | Excellent, especially in natural seawater | Resistant to uniform corrosion and moderate biofouling |

| Pitting / crevice corrosion | Good; risk increases with stagnant, highly polluted water | Avoid sustained exposure to strong chlorides + acidity |

| Stress corrosion cracking | Good resistance compared to Al‑Zn‑Mg alloys | Fit for welded marine structure applications |

| Galvanic corrosion | Potential when coupled to Cu, carbon steel, stainless steel | Mitigate via insulation, coatings, or CP systems |

9.2 Surface Treatments for Extended Life

| Treatment Type | Description | Benefit |

|---|---|---|

| Marine anodizing | Hard anodic film (typically 10–25 μm or more) | Enhanced pitting and wear resistance |

| Epoxy / polyurethane coating | Multi‑layer painted system on prepared surface | Extended service in splash & tidal zones |

| Conversion coatings | Chromate‑free pretreatments prior to painting | Improved adhesion and coating durability |

| Cathodic protection | Integration into platform CP (sacrificial anode or ICCP) | Controls galvanic corrosion |

10. Weldability & Fabrication

10.1 Welding Performance

| Item | Details |

|---|---|

| Weldability | Excellent, using MIG/GMAW or TIG/GTAW |

| Recommended filler | 5183, 5356 (select by mechanical & corrosion criteria) |

| Pre‑heat | Generally not required; avoid overheating |

| Post‑weld treatment | Usually not necessary; some applications may specify stress‑relief by design rather than heat |

Welding must consider heat input to avoid softening in the heat‑affected zone (HAZ), though 5083 is less sensitive than many higher strength aluminum alloys.

10.2 Machinability & Forming

| Operation | Notes on 5083 Hex Bars |

|---|---|

| Turning & milling | Good in hardened tempers; use sharp tools, high rake, coolant |

| Drilling | Standard high‑speed or carbide tools, appropriate chip evacuation |

| Bending | Prefer O, H111 or H112 tempers; generous radii recommended |

| Threading | Internal and external threads feasible; hex profile aids wrenching & clamping |

11. Comparison with Other Marine Aluminum Alloys

| Alloy | Type | Traits | Relative Suitability for Offshore Hex Bars |

|---|---|---|---|

| 5083 | Al‑Mg | High strength, top‑tier corrosion resistance | Excellent choice, widely used for severe seawater |

| 5086 | Al‑Mg | Slightly lower strength, excellent corrosion | Also suitable; often used in plates and extrusions |

| 5052 | Al‑Mg | Lower strength, good forming | Light‑duty brackets and non‑critical parts |

| 6061 | Al‑Mg‑Si (heat treatable) | Higher yield potential, good machinability but less seawater resistant | Used when strength & machinability weigh more than maximum corrosion resistance |

For highly exposed and mission‑critical offshore applications (splash zone, load‑bearing links), 5083 is typically preferred over 6xxx series due to its superior marine corrosion behavior.

12. Quality Standards & Certification

For offshore platform construction, compliance with recognized international and classification society standards is crucial.

12.1 Typical Standards

| Standard Family | Scope |

|---|---|

| EN 573 / EN 485 | Chemical composition and wrought products (plates, sheets) |

| EN 754 / EN 755 | Cold‑drawn and extruded bars/profiles |

| ASTM B221 | Aluminum bars, rods, shapes (extruded) |

| ASTM B211 | Aluminum bars and rods (wrought products) |

| GB/T standards | Chinese aluminum alloy standards |

12.2 Class & Project Approvals

| Certification Body | Relevant Focus |

|---|---|

| DNV (Det Norske Veritas) | Offshore structures & ships |

| ABS (American Bureau of Shipping) | Offshore units & marine applications |

| LR (Lloyd’s Register) | Marine and offshore compliance |

| BV, CCS and others | Regional/project‐specific certifications |

Mechanical test data, corrosion test reports, and mill test certificates (MTC) are commonly supplied with each batch to support project documentation and traceability.

13. Handling, Storage & Installation Recommendations

| Stage | Recommended Practice |

|---|---|

| Handling | Use non‑scarring slings; avoid metal‑on‑metal impact and scoring |

| Storage | Store under dry cover; off the ground; avoid contact with chemicals and salts |

| Protection | For long offshore transit, wrap or coat with temporary protective film/oil (where allowed) |

| Cutting | Use dedicated aluminum saw blades, avoid cross‑contamination with carbon steel |

| Installation | Prevent direct contact with dissimilar metals; use isolating gaskets, sleeves, or coatings |

14.1 General Product Specification for 5083 Marine aluminum hexagonal bars

| Item | Specification (Typical Project Baseline) |

|---|---|

| Alloy designation | EN AW‑5083 / AA5083 |

| Product form | Hot extruded and/or cold‑drawn hexagonal bar |

| Tempers available | O, H111, H112, H32 (and by agreement) |

| Dimension range (AF) | 8–120+ mm (other sizes by request) |

| Standard lengths | 3–6 m; cut‑to‑length on request |

| Standards | EN 755, ASTM B221/B211, project or class rules |

| Certification | Mill test certificate 3.1 or per project spec |

| Surface finish | Mill finish, machined, or anodized |

| Supply condition | Straightened, deburred ends, packed for marine shipment |

Related Products

6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsRelated Blog

5083 Marine Aluminum Bar for Corrosion Resistant Boat Hulls

When considering materials for seafaring vessels, especially boat hulls, durability and resistance to corrosion are of paramount importance. The evolution of marine applications largely banded around revolutionary developments in materials science.

View Details5083 5052 H32 60mm aluminum bar for boat

High-performance 5083 and 5052 H32 60mm aluminum bars tailored for marine applications. Ideal for boat building with excellent corrosion resistance, superior strength, and formability.

View Details5083 Marine Aluminum Hexagonal Bars for Durable Offshore Support Parts

Explore premium 5083 marine aluminum hexagonal bars tailored for offshore support applications. their superior corrosion resistance, alloy composition, mechanical properties, and industry implementation standards.

View Details5083 Marine Grade Aluminum Solid Bar for Offshore Vessel Frame Parts

In the demanding environment of offshore vessels, structural integrity, durability, and corrosion resistance are critical factors that determine overall vessel performance and safety.

View Details5083 Marine Aluminum Bar for Long Term Marine Equipment Support

Marine applications demand materials that can withstand harsh environments, conduct excellent performance, and provide durability for long-lasting use. One such product that has gained prominence in the marine industry is the 5083 Marine Aluminum Bar.

View Details5083 Marine Aluminum Hexagonal Bars for Offshore Platform Construction

5083 Marine Aluminum Hexagonal Bars for Offshore Platform Construction5083 marine aluminum hexagonal bars offer high strength, excellent corrosion resistance, and outstanding weldability for offshore platform construction.

View Details

Leave a Message