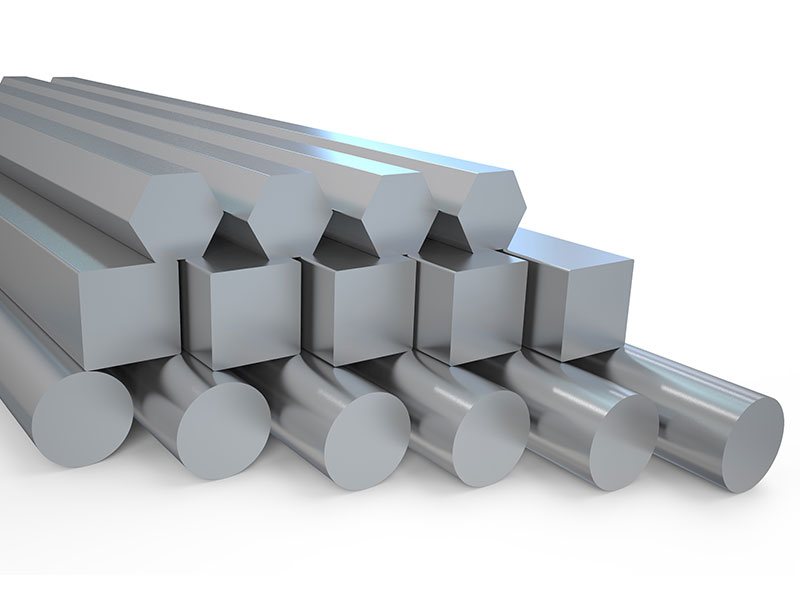

5083 Marine Aluminum Hexagonal Bars for Boat Design and Engineering

5083 Marine aluminum hexagonal bars offer outstanding corrosion resistance, high strength-to-weight ratio, and excellent weldability for boat design and marine engineering. Ideal for structural frames, fittings, brackets, and precision components, these hex bars provide reliable performance in seawater, offshore, and coastal environments.

5083 aluminum is a non-heat-treatable, high-magnesium alloy renowned in the marine industry for its:

- Superior resistance to seawater corrosion

- High strength combined with low density

- Excellent weldability and formability

In hexagonal bar form, 5083 becomes a versatile, easy-to-machine profile that is ideal for structural and precision applications in boats, yachts, work vessels, and offshore equipment. The flat sides of the hex profile allow for secure wrenching, accurate indexing, and simplified assembly compared with round bars in many engineering designs.

Features and Advantages

Marine-Grade Corrosion Resistance

5083 is specifically engineered to withstand:

- Continuous seawater immersion

- Salt spray and splash zones

- Brackish water and humid coastal atmospheres

The high magnesium content forms a stable passivation layer that protects the surface, reducing pitting and crevice corrosion in marine and offshore environments.

High Strength-to-Weight Ratio

Compared with many standard aluminum alloys, 5083 delivers higher strength while keeping weight low, enabling:

- Lighter structures without sacrificing stiffness

- Improved fuel efficiency and vessel performance

- Reduced top-weight for better stability

Excellent Weldability and Fabrication

5083 marine aluminum hex bars are compatible with common marine welding processes, including MIG and TIG, using appropriate 5xxx-series filler metals. Benefits include:

- Strong, corrosion-resistant weld zones

- Minimal loss of strength in welded areas

- Ease of fabrication for custom brackets, frames, and fittings

Dimensional Stability and Machinability

Hex bars in 5083 alloy exhibit good dimensional stability and can be:

- Precisely machined for threaded components and couplings

- Accurately indexed and clamped using flat wrenching surfaces

- Integrated into assemblies where orientation and alignment matter

Typical Applications in Boat Design and Marine Engineering

5083 Marine aluminum hexagonal bars are widely used in:

| Application Area | Typical Uses |

|---|---|

| Boat & Yacht Structures | Light frames, stiffeners, small masts, railing posts, support struts |

| Deck & Superstructure Hardware | Brackets, cleats, stanchion bases, hinge mounts, fairlead blocks |

| Mechanical & Rigging Components | Couplings, turnbuckle bodies, tensioning devices, marine fastener blanks |

| Interior & Systems Integration | Seat frames, ladder supports, instrument mounts, console frames |

| Offshore & Harbor Infrastructure | Small hardware for piers, floating docks, navigation aids |

The hex profile is particularly favored where:

- Wrench engagement is required (e.g., nuts, coupler bodies)

- Anti-rotation features are needed in composite or metal sockets

- Weight savings and corrosion resistance are critical design constraints

Chemical Composition of 5083 Marine Aluminum

Typical chemical composition (mass percent) for 5083 alloy used in marine applications:

| Element | Symbol | Typical Range (%) | Function in Alloy |

|---|---|---|---|

| Magnesium | Mg | 4.0 – 4.9 | Main strengthening element, boosts corrosion resistance |

| Manganese | Mn | 0.40 – 1.0 | Improves strength and grain structure |

| Chromium | Cr | 0.05 – 0.25 | Enhances stress-corrosion resistance |

| Iron | Fe | ≤ 0.40 | Controlled impurity; excessive levels reduce ductility |

| Silicon | Si | ≤ 0.40 | Controlled impurity |

| Copper | Cu | ≤ 0.10 | Minimized to maintain marine corrosion resistance |

| Zinc | Zn | ≤ 0.25 | Kept low to avoid stress-corrosion cracking |

| Titanium | Ti | ≤ 0.15 | Grain refiner |

| Aluminum | Al | Balance | Base metal |

Common Tempers for 5083 Hex Bars

5083 is a strain-hardenable, non-heat-treatable alloy. Strength is achieved via cold work and controlled thermal treatment rather than precipitation hardening.

| Temper | Description | Typical Use for Hex Bars |

|---|---|---|

| O | Annealed, lowest strength, maximum ductility | Deep forming, severe bending, post-machining forming |

| H111 | Slightly strain-hardened | Good formability, moderate strength, general fittings |

| H112 | As-fabricated, minimally strain-hardened | General structural bars, machining stock |

| H116 | Strain-hardened and stabilized, marine-grade | Plate-focused temper; used by reference for similar corrosion/performance expectations in bar products |

For hexagonal bars used in marine hardware and structures, H111 and H112 are commonly supplied, offering a balance of strength, machinability, and forming capability.

Mechanical Properties (Typical Values)

Representative room-temperature mechanical properties for 5083 marine aluminum bars (values are indicative and may vary with size, temper, and exact specification):

| Property | Unit | 5083-O (Typical) | 5083-H111 / H112 (Typical) |

|---|---|---|---|

| Tensile Strength (Rm) | MPa | 270 – 330 | 275 – 345 |

| 0.2% Proof Strength (Rp0.2) | MPa | 120 – 160 | 125 – 200 |

| Elongation (A50) | % | 14 – 20 | 10 – 16 |

| Brinell Hardness (HBW) | HB | 65 – 80 | 75 – 95 |

| Modulus of Elasticity | GPa | ~70 | ~70 |

| Shear Strength (approx.) | MPa | 150 – 190 | 160 – 200 |

| Density | g/cm³ | ~2.66 | ~2.66 |

These properties enable structural and hardware components that can sustain significant loads while remaining light and corrosion-resistant.

Dimensional Range and Tolerances

Hexagonal 5083 marine bars are available in a broad dimensional range, subject to mill capabilities and order quantities. Typical commercial sizes:

| Parameter | Typical Range / Note |

|---|---|

| Across Flats (A/F) Diameter | ~8 mm – 80 mm (special sizes on request) |

| Length | Common stock lengths: 3 m, 4 m, 6 m |

| Length Tolerance | Usually +50 / +100 mm (depending on mill standard) |

| Straightness | Tight straightness available for precision engineering |

| Dimensional Tolerance (A/F) | Conforms to EN, ASTM, or GB standards for extruded bar |

| Surface Condition | Mill finish; anodizing or coating optional |

For high-precision fitment (e.g., sliding sockets, precision couplers, or custom nuts), tighter tolerances can often be specified by agreement.

Physical and Thermal Properties

| Property | Unit | Typical Value for 5083 |

|---|---|---|

| Density | g/cm³ | 2.65 – 2.68 |

| Melting Range | °C | 570 – 640 |

| Coefficient of Thermal Expansion | µm/m·°C | ~24 (20–100 °C) |

| Thermal Conductivity | W/m·K | ~120 – 135 |

| Electrical Conductivity | % IACS | ~28 – 32 |

These characteristics contribute to good thermal balance on deck and in engine-room applications, and acceptable electrical properties for non-critical conductive hardware.

Corrosion Resistance in Marine Environments

5083 stands out within the 5xxx series for its seawater resistance. In appropriately selected tempers and with correct design practices, it resists:

- General corrosion in fully immersed and splash zones

- Pitting and crevice corrosion in chloride-rich seawater

- Stress-corrosion cracking when magnesium content and temper are controlled

To maximize service life:

- Avoid galvanic coupling with more noble metals (e.g., stainless steels) without proper isolation

- Use compatible marine-grade fasteners and sealants

- Ensure adequate drainage and ventilation in crevices and joints

Fabrication, Welding, and Surface Finishing

Welding

| Aspect | Recommendation |

|---|---|

| Typical Processes | MIG and TIG welding with 5xxx-series filler wires |

| Filler Metals | ER5183, ER5356, or equivalents (verify design spec) |

| Weld Properties | High joint efficiency, good corrosion resistance |

| Pre/Post Treatment | Generally no post-weld heat treatment required |

Machining and Forming

| Process | Notes for 5083 Hex Bars |

|---|---|

| Machining | Use sharp tools, moderate cutting speeds, adequate lubrication |

| Bending | Best in O or H111 temper for tighter radii |

| Sawing | Carbide-tipped blades recommended |

| Threading | Suitable for cut threads in fittings, couplers, and connectors |

Surface Finishes

5083 hex bars can be supplied as:

| Finish Type | Description / Benefit |

|---|---|

| Mill Finish | Standard; suitable for most structural applications |

| Anodized | Enhanced surface hardness and additional corrosion layer |

| Painted / Coated | Color coding, aesthetic enhancement, added protection |

Quality Standards and Certification

5083 Marine aluminum hexagonal bars are commonly produced in accordance with:

| Standard / Specification | Scope |

|---|---|

| ASTM B211 / B221 | Aluminum and aluminum-alloy bars and extrusions |

| EN 573 / EN 755 Series | Chemical composition and mechanical properties |

| Classification Society Rules | DNV, ABS, BV, LR approvals where applicable |

Mill test certificates and full traceability are generally available to support classification society requirements and marine project documentation.

Choosing 5083 Hex Bars for Your Marine Project

For designers, builders, and marine engineers, 5083 hexagonal bars provide a strong combination of:

- Long-term durability in seawater

- Lightweight structural performance

- Reliable weldability and fabrication flexibility

- Convenient hex geometry for assembly and maintenance

They are well-suited to both new-build and refit projects, from performance yachts to workboats and offshore structures. When specifying, consider:

- Required temper and mechanical properties

- Dimensional range and tolerance class

- Surface finish and any post-processing (anodizing, machining, welding)

- Compatibility with surrounding materials and fasteners

Well-specified 5083 marine aluminum hex bars can significantly improve reliability, reduce maintenance, and contribute to safer, more efficient marine designs.

Related Products

Marine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsRelated Blog

5083 Marine Aluminum Bar for High Strength Marine Vessel Parts

5083 Marine Aluminum Bar for High Strength Marine Vessel Parts: Durability Meets PerformanceWhen it comes to constructing high-performance marine vessels, material selection is paramount.

View Details5083 Marine Grade Aluminum Solid Bar for Boat Hull Reinforcement

In the expansive world of marine construction and engineering, selecting the right materials can make the difference between a resilient vessel and costly structural failures.

View Details5083 Marine Aluminum Bar for Long Term Marine Equipment Support

Marine applications demand materials that can withstand harsh environments, conduct excellent performance, and provide durability for long-lasting use. One such product that has gained prominence in the marine industry is the 5083 Marine Aluminum Bar.

View Details5083 Marine Aluminum Bar for Saltwater Corrosion Resistant Boat Frames

In the demanding marine environment, selecting the right materials for boat frames is vital to ensuring longevity, performance, and safety. Among the myriad of alloys.

View Details5083 Marine Aluminum Hexagonal Bars for Durable Offshore Support Parts

Explore premium 5083 marine aluminum hexagonal bars tailored for offshore support applications. their superior corrosion resistance, alloy composition, mechanical properties, and industry implementation standards.

View Details5083 Marine Grade Aluminum Solid Bar for Custom Marine Construction

The 5083 Marine Grade Aluminum Solid Bar is a highly regarded alloy, specifically designed to meet the stringent demands of the marine environment. Renowned for its exceptionally high resistance to corrosion, strength, and weldability.

View Details

Leave a Message