6061 Marine Aluminum Hexagonal Bars for Corrosion Resistant Marine Applications

6061 Marine Aluminum Hexagonal Bars for Corrosion Resistant Marine Applications: Unveiling the Technical Backbone of Modern Maritime Engineering

In the demanding world of marine engineering, materials used must offer more than structural integrity—they must exhibit exceptional resistance to corrosion in aggressive salty environments, maintain dimensional stability, and provide ease of fabrication. Amid numerous alloys, 6061 marine aluminum hexagonal bars stand distinct. their unique characteristics, elemental composition, temper conditions, and versatile applications opens a window into why they are now cornerstones in marine infrastructure and vessel manufacturing.

The Unique Appeal of 6061 Aluminum Alloy in Marine Contexts

6061 is an aluminum alloy that contains Magnesium (Mg) and Silicon (Si) as its major alloying elements. This alloy is well-recognized for its excellent balance of strength, corrosion resistance, toughness, and good machinability—qualities imperative for components submerged or exposed to seawater.

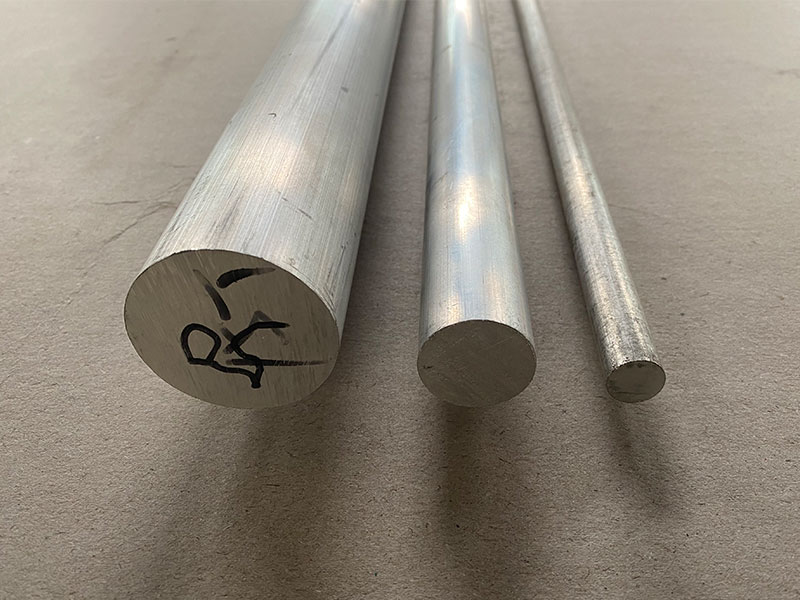

Why Choose Hexagonal Bars?

Hexagonal bars inherently provide geometrical advantages in assembling marine parts such as fasteners, brackets, shafts, and connectors that need standardized gripping and torque application without slippage. Compared to round bars or rectangular billets, hexagonal bars facilitate multi-plane machining and threading while preserving cross-sectional strength—a critical feature for marine hardware subject to dynamic loads.

Chemical Composition and Corrosion Resistance: The Heart of 6061 Alloy’s Marine Use

The corrosion resistance comes primarily through its carefully balanced chemical composition and post-processing heat treatments. Here’s the typical chemical composition of 6061 alloy:

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 0.8 – 1.2 |

| Silicon (Si) | 0.4 – 0.8 |

| Iron (Fe) | 0.7 max |

| Copper (Cu) | 0.15 – 0.4 |

| Manganese (Mn) | 0.15 max |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | 0.25 max |

| Titanium (Ti) | 0.15 max |

Magnesium and Silicon form magnesium silicide (Mg2Si), which contributes both to corrosion resistance and hardening through aging processes.

Alloy Temper Designations and Their Marine-Apt Applicability

6061 aluminum bars come in various TEMPERS indicated by T-numbers showing different treatment methods to accentuate mechanical properties:

- 6061-O (Annealed): Soft, ductile state, easier for shaping but lower strength.

- 6061-T4 (Solution Heat Treated + Naturally Aged): Intermediate strength; good formability.

- 6061-T6 (Solution Heat Treated + Artificially Aged): Probably the most common condition providing optimum strength and corrosion resistance with a tensile strength around 290 MPa (~42000 psi).

For marine environments where strength and corrosion resistance are paramount, 6061-T6 is the favored temper due to its balanced configuration and hardness enabling long operational life.

Critical Parameters and Industry Implementation Standards

Marine components fabricated from 6061 marine aluminum hexagonal bars must meet various precise industry standards ensuring their performance in extreme conditions:

- ASTM B210: Covers the standard specification for aluminum and aluminum-alloy drawn bars, rods, and wires.

- MIL-A-8625: Outlines anodizing processes applicable to enhance oxide thickness for increased corrosion resistance.

- ISO 11960: Reference for seamless hexagonal bars suited spécialement for structural uses.

Mechanical properties of 6061-T6 hex bars confidently surpass tensile, yield, and elongation requirements of these norms while possessing exceptional anodization receptivity critical for improved marine atmosphere protection.

Revolutionary Functions within Marine Applications

1. Structural Framework & Support Systems

The hexagonal nature and high tensile strength make 6061 aluminum bars perfect for frameworks onboard ships—gun mounts, mast fittings, and rigging components where corrosion plus strength fusion dictates operational safety.

2. Fasteners, Valves & Electrical Connectors

Hexagonal epoxy-coated or anodized 6061 bars achieve accuracy in CNC machining. The form ensures excellent torque transfer; the material’s excellent corrosion resistance minimizes maintenance 0 issues in submerged sections such as valves, piping flange bolts, nuts, and grounding electrodes.

3. Propulsion & Steering Components

Marine steering shafts, gears, and linkage adapters crafted from 6061 series minimize weight and increase corrosion endurance. This enhances fuel efficiency while maintaining long-service lifespan under constant seawater exposure.

Related Products

Marine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsRelated Blog

6061 Marine Aluminum Hexagonal Bars for Corrosion Resistant Marine Applications

6061 Marine Aluminum Hexagonal Bars for Corrosion Resistant Marine Applications: Unveiling the Technical Backbone of Modern Maritime EngineeringIn the demanding world of marine engineering.

View Details6061 Marine Aluminum Hexagonal Bars for Lightweight Marine Frame Construction

In the ever-evolving marine industry, choosing the correct material for frame construction is a critical factor influencing performance, durability, and safety. Among these materials.

View Details6061 Marine Grade Aluminum Solid Bar for Marine Vessel Frame Parts

The 6061 Marine Grade Aluminum Solid Bar is a premium-quality aluminum alloy widely recognized for its exceptional strength, corrosion resistance, and versatility.

View Details6061 Marine Grade Aluminum Solid Bar for Boat Hull and Deck Strengthening

When it comes to constructing or reinforcing boats, durability, strength, and corrosion resistance are non-negotiable attributes. Among the available materials in marine applications.

View Details

Leave a Message