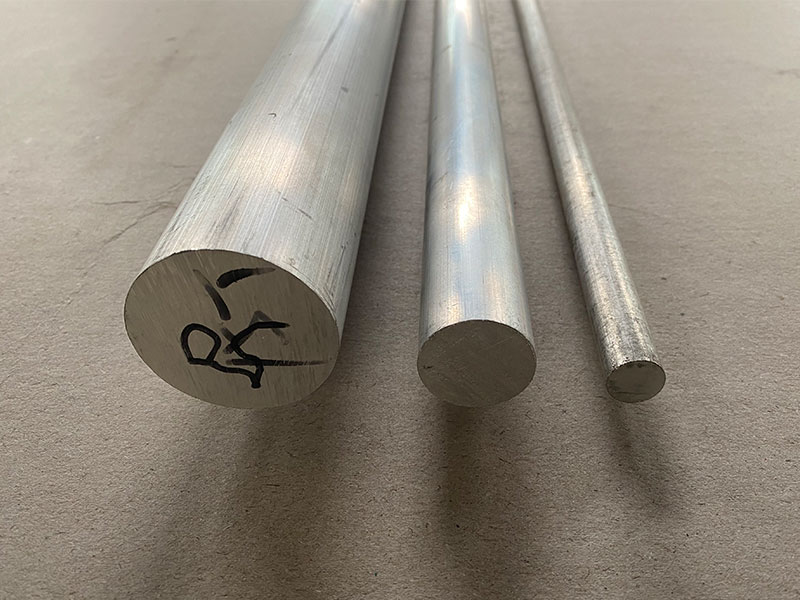

6061 Marine Grade Aluminum Solid Bar for Boat Hull and Deck Strengthening

When it comes to constructing or reinforcing boats, durability, strength, and corrosion resistance are non-negotiable attributes. Among the available materials in marine applications, 6061 marine grade aluminum solid bar stands out as a versatile and superior option for enhancing boat hulls and decks.

6061 Marine Grade Aluminum Solid Bar

6061 aluminum alloy is known for its exceptional mechanical properties, corrosion resistance, and ease of fabrication, making it ideal for marine use. It belongs to the 6xxx series, where magnesium (Mg) and silicon (Si) form the primary alloying elements.

Marine grade 6061 typically denotes that the alloy adheres to standards suited for maritime applications with specifications ensuring optimal resistance to saltwater corrosion―a crucial factor in prolonging structural integrity on marine vessels.

Chemical Composition of 6061 Alloy (Typical Range - per ASTM B209 / AMS-0401 standards)

| Element | Weight % |

|---|---|

| Aluminum (Al) | Balance (approx. 97.9%) |

| Magnesium (Mg) | 0.8 – 1.2 |

| Silicon (Si) | 0.4 – 0.8 |

| Iron (Fe) | 0.0 – 0.7 |

| Copper (Cu) | 0.15 – 0.40 |

| Zinc (Zn) | 0.25 max |

| Chromium (Cr) | 0.04 – 0.35 |

| Manganese (Mn) | 0.15 max |

| Titanium (Ti) | 0.15 max |

Note: Trace atomic elements may vary based on supplier and specific marine grade requirements.

Physical and Mechanical Parameters

6061 marine grade aluminum solid bars exhibit the following typical parameters depending on the temper condition (T6 is the most common):

| Property | Unit | 6061-T6 Marine Grade Aluminum |

|---|---|---|

| Density | g/cm³ | 2.70 |

| Ultimate Tensile Strength (UTS) | MPa | 310 – 350 |

| Yield Strength (0.2% offset) | MPa | 275 – 310 |

| Elongation at break | % | ≥10 |

| Rockwell Hardness (B scale) | HRB | 95 – 100 |

| Modulus of Elasticity | GPa | 68.9 |

| Thermal Conductivity | W/m-K | ~167 |

| Electrical Conductivity | % IACS | 40 – 45 |

Air Tempering & Alloy Treatment

6061 aluminum undergoes precipitation hardening, whereby the alloy is dissolved at elevated temperature, precipitated, and quenched resulting in increasing strength and hardness:

- T4 Temper: Solution heat-treated and naturally aged. Used when flexibility with slight strength is needed (lower stress marine components).

- T6 Temper: Solution heat-treated and artificially aged, offering maximum strength and hardness―ideal for load-bearing beam replacements underlying the hull or deck.

Boosted tempering provides better mechanical strength vital for structural parts which regularly endure fatigues, impacts, and variable loading in seas.

Applications in Boat Hull and Deck Strengthening

1. Hull Reinforcement and Keel Plates

Marine aluminum 6061-T6 solid bars are widely preferred for reinforcements inside hull frames and profile stiffeners. Its excellent strength complements welding and bolting work while resisting long-term exposure to maritime environments. Reinforced hulls constructed with 6061 ensure lump-free sites offering exceptional resistance to bending, abrasion, and torsional stresses during rough sea conditions.

2. Deck Support Beams and Stringers

For wooden or aluminum deck strengthening, 6061 bars serve as superior internal brace material; reducing flex and mitigating torsioning resulting from heavy loads or adverse wave impacts. The alloy's excellent ductility helps absorb and distribute impacts without brittle failures.

3. Structural Machined Parts

Machinists rely on 6061 marine bars as feedstock when producing custom brackets, rails, fasteners, or supports critical in joining multiple hull/deck panels. Precise alloying ensures enhanced surface finishing, consistent dimensional stability, and resilient performance.

Implementation Standards and Marine Certification

Manufacturers of marine-grade 6061 aluminum follow rigorous guidelines, typically based on:

- ASTM B221: Aluminum and aluminum-alloy extrusion bars, rods, wire, profiles, and tubes.

- AMS 4331/4037 (Aerospace machining specs translatable to marine parts with corrosion coating).

- ISO 11125 & ISO 9223 Final (corrosion resistance and life cycle assurance on marine alloys).

These compliances guarantee repeatability in chemical content, uniform temper stages, and conformance granting confidence for builders engaging in extensive saltwater-engaged environments.

Corrosion Resistance in Marine Environments

6061 possesses admirable corrosion resistance in various aqueous settings but requires anodizing or marine coatings when used as exposure surfaces, reinforcing hull/deck types where continuous immersion/spray occurs. Magnesium content promotes a thin and protective oxide somewhere reducing galvanic corrosion even in saltwater conditions.

The alloy’s maintenance of structural toughness helps it fare beyond common stainless steel variants, which may suffer severe localized pitting under marine duel.

Related Products

Marine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsRelated Blog

6061 Marine Aluminum Hexagonal Bars for Lightweight Marine Frame Construction

In the ever-evolving marine industry, choosing the correct material for frame construction is a critical factor influencing performance, durability, and safety. Among these materials.

View Details6061 Marine Grade Aluminum Solid Bar for Boat Hull and Deck Strengthening

When it comes to constructing or reinforcing boats, durability, strength, and corrosion resistance are non-negotiable attributes. Among the available materials in marine applications.

View Details6061 Marine Aluminum Hexagonal Bars for Corrosion Resistant Marine Applications

6061 Marine Aluminum Hexagonal Bars for Corrosion Resistant Marine Applications: Unveiling the Technical Backbone of Modern Maritime EngineeringIn the demanding world of marine engineering.

View Details6061 Marine Grade Aluminum Solid Bar for Marine Vessel Frame Parts

The 6061 Marine Grade Aluminum Solid Bar is a premium-quality aluminum alloy widely recognized for its exceptional strength, corrosion resistance, and versatility.

View Details

Leave a Message