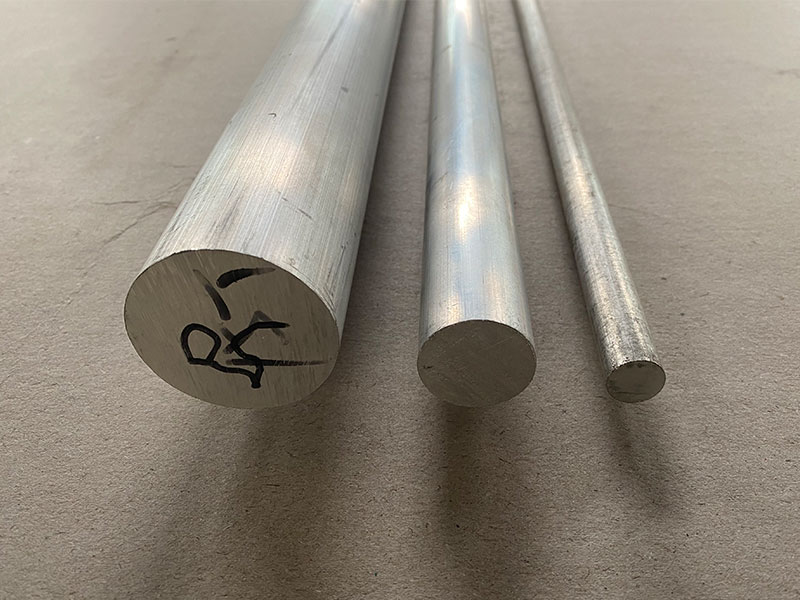

6061 Marine Grade Aluminum Solid Bar for Marine Vessel Frame Parts

The 6061 Marine Grade Aluminum Solid Bar is a premium-quality aluminum alloy widely recognized for its exceptional strength, corrosion resistance, and versatility. Specifically engineered to meet the demanding requirements of marine vessel frame parts, this alloy offers superior performance in harsh saltwater environments while maintaining ease of fabrication and excellent mechanical properties. It is the preferred choice for marine engineers and manufacturers keen on improving vessel longevity and safety.

Chemical Composition

The 6061 aluminum alloy is a heat-treatable alloy belonging to the 6xxx series, primarily alloyed with magnesium and silicon. The careful balance of alloying elements ensures outstanding corrosion resistance and strength.

Working with 6061 marine grade aluminum solid bar for vessel frame parts presents a fascinating blend of material science and practical application. We see firsthand the benefits of its exceptional strength-to-weight ratio, crucial for minimizing a vessel's overall weight and maximizing payload capacity. However, the seemingly straightforward "marine grade" designation masks a level of complexity. The actual corrosion resistance isn't inherent to the alloy itself; it's heavily reliant on proper surface preparation before welding or anodizing. We've had instances where seemingly minor flaws in pre-processing led to accelerated corrosion, highlighting the importance of meticulous quality control throughout the supply chain. Our team constantly scrutinizes incoming material for subtle imperfections – even slight variations in surface texture can impact the final weld quality and long-term performance of the vessel frame.

Personally, I find the machining aspect incredibly rewarding. 6061 is relatively easy to machine, offering a good balance of machinability and strength. Yet, achieving the precise tolerances demanded for intricate frame components requires a deft hand and an of tool wear. The satisfaction of seeing a complex part emerge from the CNC machine, knowing it will contribute to a vessel's structural integrity and longevity, is incredibly motivating. Witnessing these parts eventually installed in a finished vessel, whether a sleek yacht or a rugged workboat, reinforces the tangible impact of our work and the critical role of this seemingly simple aluminum bar in a complex engineering project.

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 0.8 - 1.2 |

| Silicon (Si) | 0.4 - 0.8 |

| Iron (Fe) | 0.7 maximum |

| Copper (Cu) | 0.15 - 0.4 |

| Manganese (Mn) | 0.15 maximum |

| Chromium (Cr) | 0.04 - 0.35 |

| Zinc (Zn) | 0.25 maximum |

| Titanium (Ti) | 0.15 maximum |

Features

1. Superior Corrosion Resistance

6061 marine grade aluminum solid bar resists corrosion from saltwater, reducing maintenance needs and extending the lifespan of vessel frame parts. Its natural oxide layer, combined with magnesium and silicon, protects against rust and pitting common in marine environments.

2. High Strength-to-Weight Ratio

The alloy provides excellent mechanical strength, allowing frame parts to maintain structural integrity while minimizing weight. This feature contributes to overall fuel efficiency and enhances the vessel’s handling characteristics.

3. Excellent Weldability

6061 aluminum solid bars are highly weldable with a range of welding techniques, ensuring that the integrity of marine vessel frames isn’t compromised when joining or fabricating.

4. Good Machinability

The bar can be readily machined into complex parts with precision, lowering manufacturing costs and making the alloy highly adaptable during the fabrication process.

5. Good Thermal Conductivity and Dimensional Stability

It maintains dimensional accuracy under temperature fluctuations which occur due to engine heat or external marine weather, vital for frame component reliability.

Mechanical Properties of 6061-T6 Aluminum Solid Bar

| Property | Value |

|---|---|

| Density | 2.70 g/cm³ |

| Tensile Strength | 290 MPa (42,000 psi) |

| Yield Strength | 240 MPa (35,000 psi) |

| Elongation at Break | 12-17% |

| Hardness (Brinell) | 95 HB |

| Modulus of Elasticity | 69 GPa |

*Note: Properties are typical for solution heat-treated and artificially aged 6061-T6 alloy.

Typical Applications in Marine Vessel Frames

- Hull Structural Frames: The lightweight yet strong characteristic of 6061 aluminum bars makes them ideal for constructing hull frames, which require both strength and corrosion resistance.

- Deck Support Beams: Endures dynamic loading conditions and marine weather exposure.

- Transoms and Bulkheads: Offers robust support structures with resistance to salty environments to avoid corrosion fatigue.

- Superstructure Components: Helps in weight optimization while providing high mechanical properties.

- Cross Members and Stringers: Improves stiffness and longevity while resisting metal fatigue caused by vibrational forces on marine vessels.

Advantages Over Other Common Marine Metals

Compared to stainless steel and other fats used in marine structural parts, 6061 marine grade aluminum provides:

| Property | 6061 Aluminum Solid Bar | Stainless Steel |

|---|---|---|

| Weight | Approximately 1/3rd the density of steel, improving weight and fuel economy | Heavier, impacting vessel performance and fuel consumption |

| Corrosion Resistance | High in saline environments without need for heavy coatings | Good corrosion resistance but prone to crevice corrosion and requires extensive maintenance |

| Strength-to-Weight Ratio | Excellent | High strength but heavier |

| Fabrication Ease | Easily extruded, machined, welded | More difficult to machine; welding requires precision |

| Cost | Generally lower | Higher cost for material and fabrication |

For marine vessel manufacturers and marine engineers seeking durable, lightweight, and corrosion-resistant material for vessel frame parts, the 6061 Marine Grade Aluminum Solid Bar represents an optimal choice. Its superior corrosion resistance in ocean environments, combined with high strength and excellent machinability, strongly supports various structural marine applications, improving operational efficiency and shielding against costly repairs due to corrosion damage.

Contact us today for availability, custom sizing, and further technical consultation to implement 6061 Aluminum Solid Bars in your marine vessel projects. We deliver high-quality material tailored to meet rigorous marine industry standards.

Related Products

Marine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsRelated Blog

6061 Marine Grade Aluminum Solid Bar for Boat Hull and Deck Strengthening

When it comes to constructing or reinforcing boats, durability, strength, and corrosion resistance are non-negotiable attributes. Among the available materials in marine applications.

View Details6061 Marine Grade Aluminum Solid Bar for Marine Vessel Frame Parts

The 6061 Marine Grade Aluminum Solid Bar is a premium-quality aluminum alloy widely recognized for its exceptional strength, corrosion resistance, and versatility.

View Details6061 Marine Aluminum Hexagonal Bars for Lightweight Marine Frame Construction

In the ever-evolving marine industry, choosing the correct material for frame construction is a critical factor influencing performance, durability, and safety. Among these materials.

View Details6061 Marine Aluminum Hexagonal Bars for Corrosion Resistant Marine Applications

6061 Marine Aluminum Hexagonal Bars for Corrosion Resistant Marine Applications: Unveiling the Technical Backbone of Modern Maritime EngineeringIn the demanding world of marine engineering.

View Details

Leave a Message