6061 Marine Aluminum Tubes for Custom Boat Frame Solutions

When it comes to constructing custom boat frames, marine-grade materials play a crucial role in ensuring longevity, safety, and performance. Among the vast selection of marine-grade metals, 6061 marine aluminum tubes is know as a top choice for designers and engineers aiming for optimal strength-to-weight ratio, corrosion resistance, and ease of fabrication.

Why Choose 6061 Marine Aluminum Tubes for Custom Boat Frames?

6061 aluminum alloy is a precipitation-hardened aluminum-magnesium-silicon product, prized in marine applications due to its exceptional all-around performance. Unlike other alloys, 6061 marine aluminum tubes combine mechanical sturdiness with chemical resistance tailored for harsh saltwater environments. This is why parts like boat frames often benefit greatly from this alloy used in tube form – granting design flexibility while maintaining structural integrity.

Working with 6061 marine aluminum tubes for custom boat frames offers a unique set of advantages and challenges. The material's strength-to-weight ratio is unparalleled, allowing for lighter, faster, and more fuel-efficient vessels. However, the fabrication process demands precision. Improper welding techniques, especially on thicker gauge tubes, can easily lead to porosity or cracking, compromising the structural integrity of the frame. We've seen firsthand the importance of pre- and post-weld heat treatments to minimize stress and ensure optimal corrosion resistance in the marine environment. Careful selection of filler materials is also crucial; using an inappropriate alloy can lead to galvanic corrosion, a common and costly failure mode. the nuances of 6061's behavior during bending and forming is also essential to avoid warping or cracking during frame construction.

Beyond the technical aspects, collaborating with boat designers and builders is key. their specific needs, whether it's accommodating a unique hull design or integrating specialized fittings, allows us to optimize tube sizing and configurations. We've found that close communication and proactive problem-solving throughout the design and fabrication phases prevent costly rework and delays. For example, a seemingly minor detail like the radius of bends can significantly affect the overall strength and fatigue life of the frame. Therefore, leveraging our expertise in material properties and fabrication techniques in conjunction with the designer's vision is critical for delivering a robust and reliable custom boat

Defining Parameters and Implementation Standards

According to ASTM International, the standard most relevant here is ASTM B221, which specifies the manufacturing, tolerances, and testing workflows for aluminum tubes and pipes used in structural applications. Implementation of these standards means the tubes enjoy strict dimensional accuracy and integrity in extrusion, single or double hermetic anneals depending on how you intend the temper.

Some parameters often required include outer diameters typically ranging between 6mm to over 300mm according to customization needs, and wall thicknesses from 1mm to 20mm — critical especially for lasting structural performance under load.

Alloy Tempering and Mechanical Properties: The T6 Temper Example

One of the classic tempers for 6061 marine aluminum tubes is the T6 temper, which entails solution heat treatment followed by artificial aging. This temper greatly enhances mechanical properties and fatigue resistance—very important for boat frames exposed to continuous cyclic stresses and salt spray. For custom marine use:

- Tensile Strength: 310 MPa (45,000 psi) minimum

- Yield Strength: 275 MPa (40,000 psi) minimum

- Elongation: ≥ 8% (measured in 2 inches)

Such breakdown stands as a guarantee—the frame refuses premature deformation or cracking despite heavy operational demands.

Chemical Composition Naturally Optimized for Marine Conditions

Unlike structural steels, 6061’s composition confers a very robust shield against seawater corrosion; its magnesium and silicon content acts synergistically with aluminum, forming a stable oxide layer protective against corrosive attacks. Here’s that chemical composition fully integrated as per IPC designation / ASTM findings:

| Element | Weight % Typical Range |

|---|---|

| Aluminum | Balance (approx. 97.9%) |

| Magnesium | 0.8% - 1.2% |

| Silicon | 0.4% - 0.8% |

| Iron | ≤ 0.7% |

| Copper | ≤ 0.4% |

| Zinc | ≤ 0.25% |

| Chromium | ≤ 0.35% |

| Manganese | ≤ 0.15% |

| Titanium | ≤ 0.15% |

This nuanced blend results in an alloy skilled at self-healing microscopic barriers essential for marine longevity.

Practical Implementation: Welding and Fabrication of Marine-grade Tubes

A distinctive facet regarding 6061 marine aluminum tubes lies in their machinability and weldability. Machines shaping your custom frames benefit significantly from 6061’s responsiveness to common metalworking techniques—MIG and TIG welding being foremost. When welded correctly with filler aluminum alloys without contamination, the often-quoted drop in strength within the heat-affected zones is minimized.

Endorsement for Marine Custom Boat Frame Solutions

Adopting 6061 aluminum marine tubes for framework ensures your boat design boasts cost-effective mass optimization, resistance to saltwater admissible corrosion, and tech integrity enshrined in recognized industry testing standards. Whether you’re a boat building company, marine architect, or custom frame fabricator, trusting 6061 T6 aluminum tubes informed by ASTM B221 protocols and chemical optimization allows creating longer-lasting, lightweight, and highly durable marine structures that bring innovation to smooth waters.

Final Thoughts

Selecting the right marine material can never be undervalued in boatframe customization. With its fatty acid-resistant metalwork resistance, validated chemical contents, and dependable mechanical properties in the T6 temper, 6061 marine aluminum tubes undoubtedly hold an authoritative position for marine grade structural tube fabrication.

Seeking premium marine tubes synthesis with next-level yield and integrity? Investigate products clearly marked 6061 T6, conforming to ASTM marine material sea-use guidelines — and sail into next-level marine fabrication confidence.

For any customized requirements on 6061 marine marine aluminum tubes or queries on adapting technical parameters and compliances into your custom boat design, our specialists are available for consultation. Harness marine aluminum engineering proficiency and unrivaled application wisdom.

Related Products

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

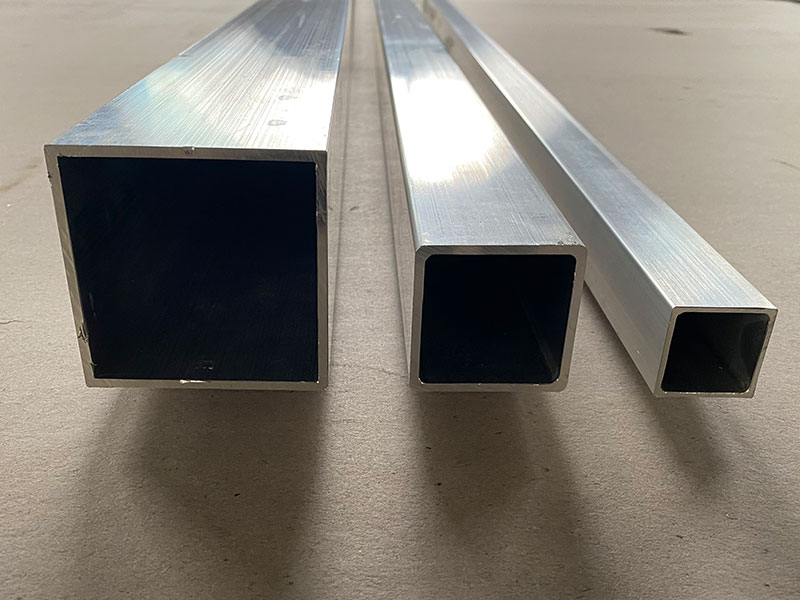

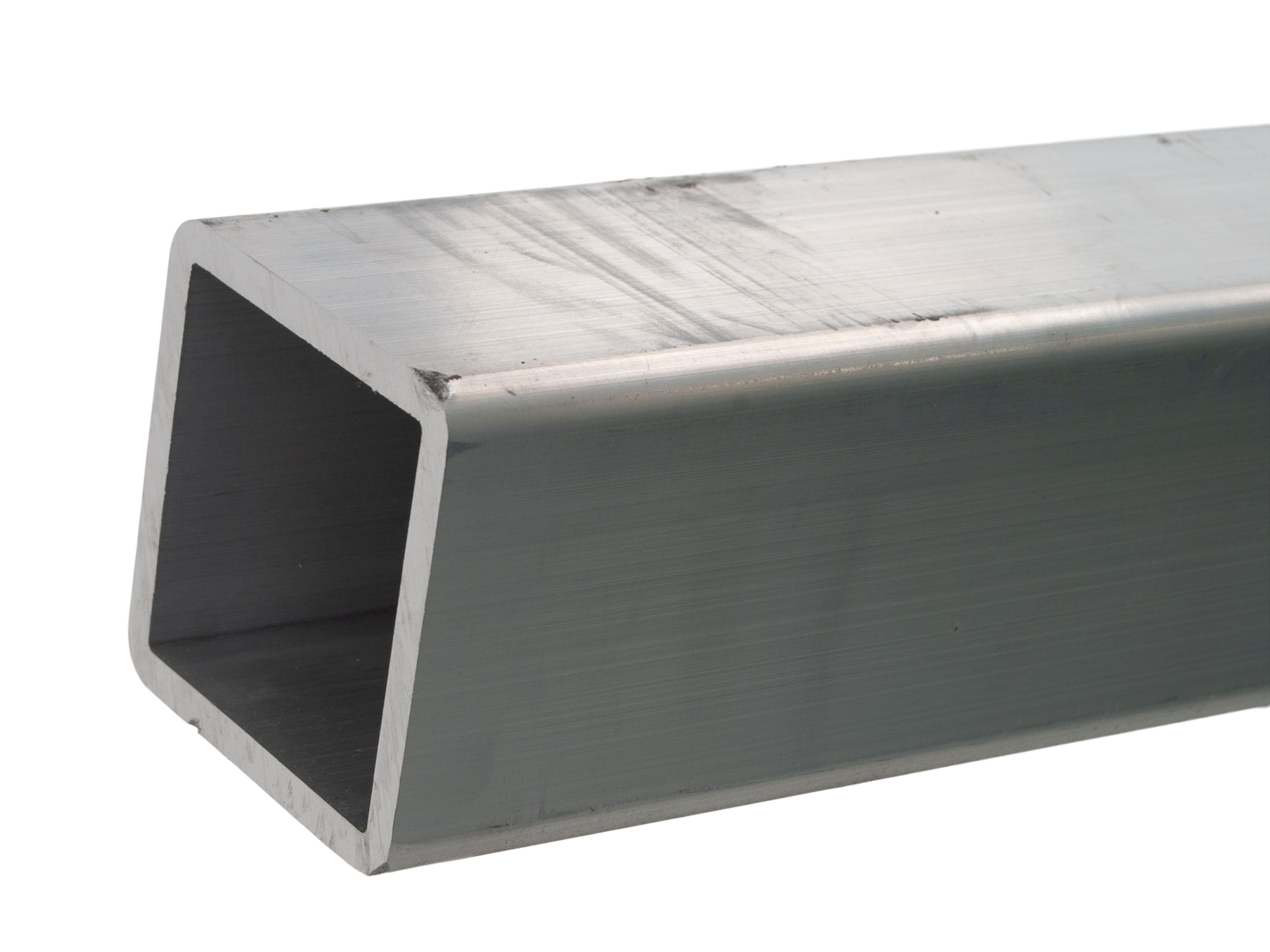

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsRelated Blog

6061 Marine Aluminum Tubes for Marine Engineering Projects

Marine engineering demands materials that combine exceptional strength, corrosion resistance, and versatility for reliable performance in harsh seawater environments.

View Details6061 Marine Aluminum Square Tubes for Yacht Construction

In the realm of yacht construction, materials play a pivotal role in defining vessel performance, durability, and aesthetics.

View Details6061 Marine Aluminum Tubes for Custom Boat Frame Solutions

When it comes to constructing custom boat frames, marine-grade materials play a crucial role in ensuring longevity, safety, and performance. Among the vast selection of marine-grade metals.

View Details6061 Marine Aluminum Tubes for Custom Marine Construction

When it comes to building robust, lightweight, and corrosion-resistant structures for marine applications, 6061 Marine Aluminum Tubes unquestionably lead the pack.

View Details

Leave a Message