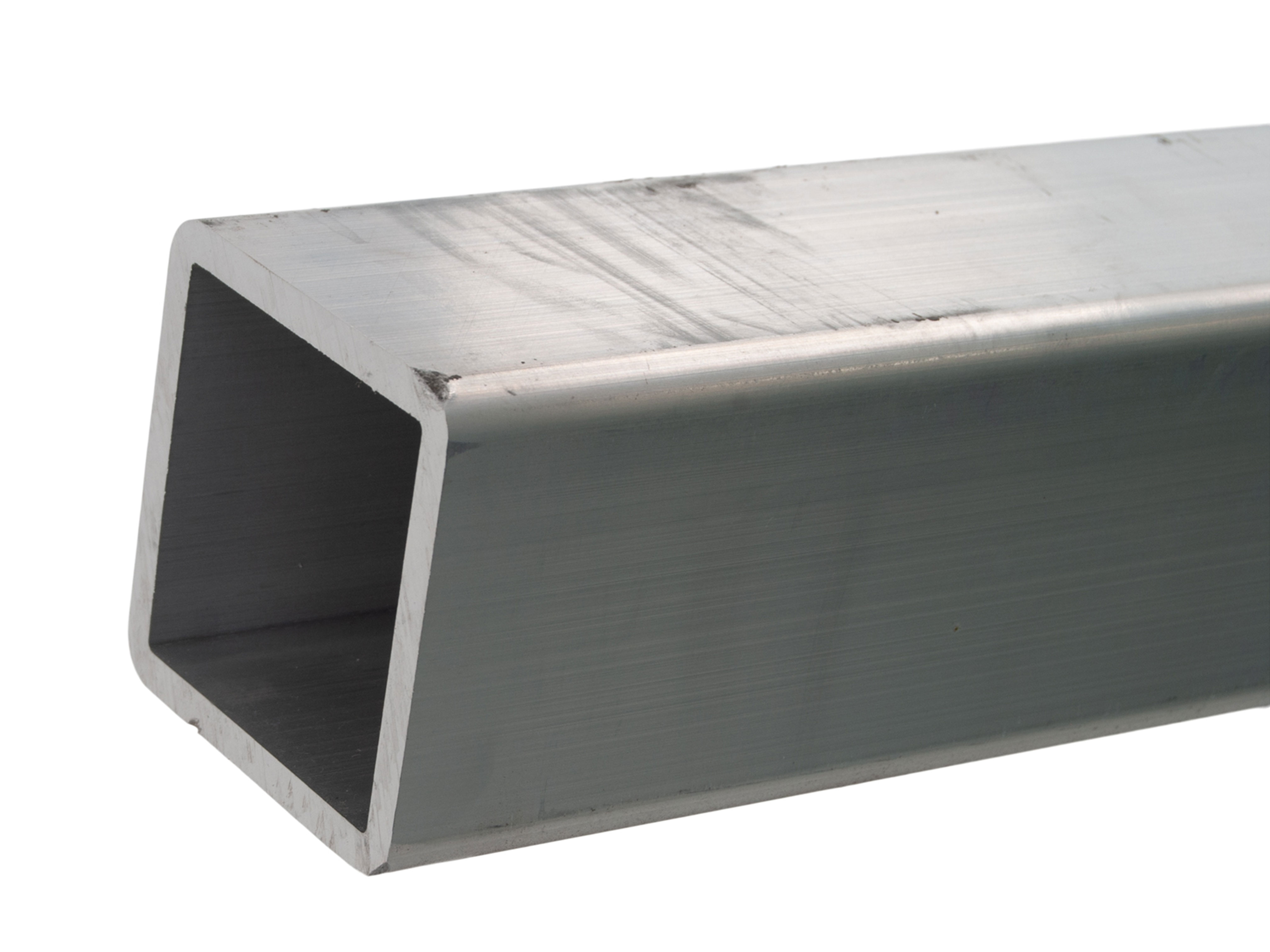

Marine Grade Aluminum Rectangular Tubes are precision-engineered structural profiles designed to perform exceptionally in marine and offshore applications. Manufactured from premium marine-grade aluminum alloys, these tubes combine outstanding corrosion resistance, superior strength-to-weight ratio, and excellent versatility in fabrication. Their rectangular cross-sectional shape provides enhanced rigidity and ease of integration, making them integral components in shipbuilding, offshore platforms, coastal infrastructure, and marine equipment fabrication.

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness. The rectangular profile offers structural stability, uniform strength distribution, and optimal surface area for mounting and assembly compared to other tube shapes.

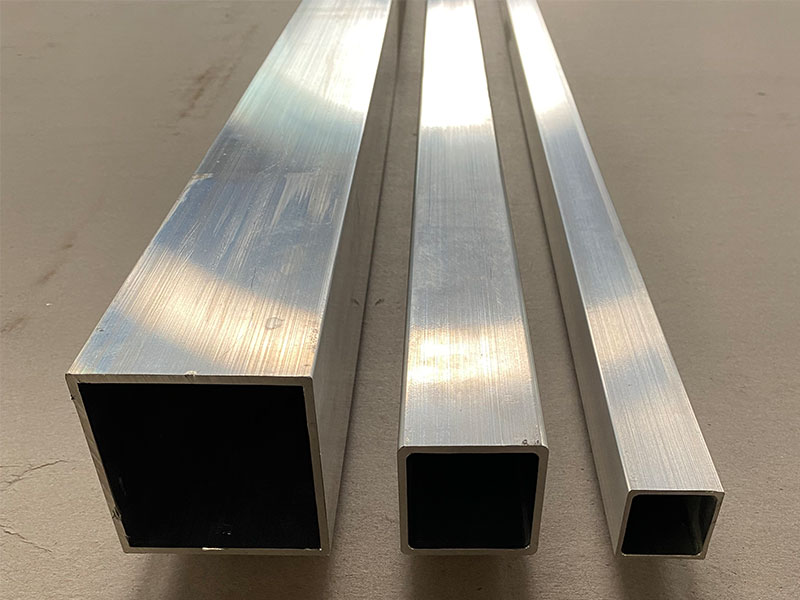

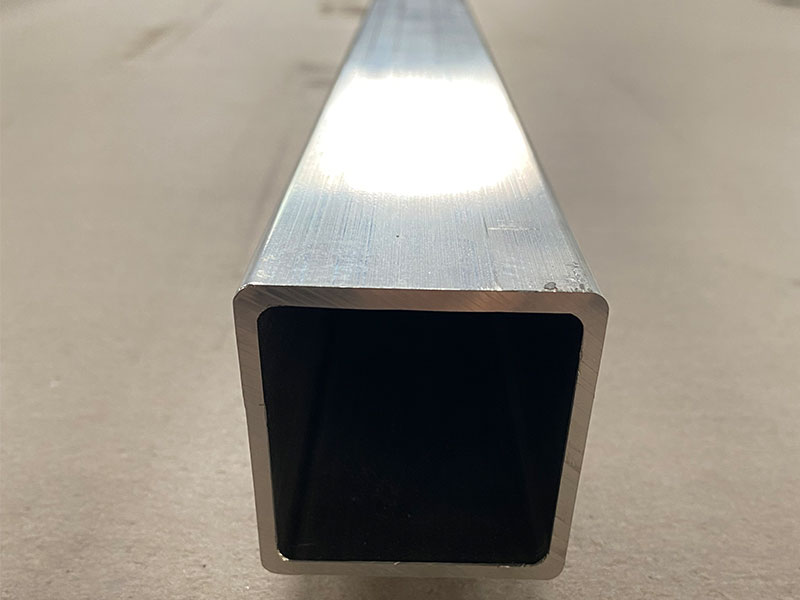

Utilizing advanced extrusion or seamless rolling manufacturing processes, these tubes maintain precise dimensional tolerances, consistent wall thickness, and smooth surface finishes. Available in a broad range of sizes and thicknesses, they deliver significant design flexibility for a variety of marine structural and equipment applications.

Common Marine Aluminum Alloys for Rectangular Tubes

| Alloy | Characteristics | Typical Marine Uses |

|---|---|---|

| 5083 | High Mg content (4.0-4.9%), excellent corrosion resistance | Ship frames, offshore structural tubes |

| 5052 | Moderate Mg (2.2-2.8%), excellent formability & corrosion resistance | Lightweight fabricated parts, railings |

| 6061 | Heat treatable, good strength and machinability | Load-bearing tubes, machined marine components |

| 6082 | High strength 6xxx series, improved corrosion resistance | Shafts, masts, and marine structural tubing |

Chemical Composition (Representative)

| Element | 5083 (%) | 5052 (%) | 6061 (%) | 6082 (%) |

|---|---|---|---|---|

| Magnesium (Mg) | 4.0 – 4.9 | 2.2 – 2.8 | 0.8 – 1.2 | 0.6 – 1.2 |

| Silicon (Si) | ≤ 0.4 | ≤ 0.25 | 0.4 – 0.8 | 0.7 – 1.3 |

| Chromium (Cr) | 0.05 – 0.25 | 0.15 – 0.35 | 0.04 – 0.35 | 0.25 – 0.45 |

| Copper (Cu) | ≤ 0.1 | ≤ 0.1 | 0.15 – 0.4 | ≤ 0.1 |

| Iron (Fe) | ≤ 0.4 | ≤ 0.4 | ≤ 0.7 | ≤ 0.5 |

| Manganese (Mn) | 0.4 – 1.0 | ≤ 0.1 | ≤ 0.15 | 0.4 – 1.0 |

| Zinc (Zn) | ≤ 0.25 | ≤ 0.1 | ≤ 0.25 | ≤ 0.2 |

| Titanium (Ti) | ≤ 0.15 | ≤ 0.03 | ≤ 0.15 | ≤ 0.1 |

| Aluminum (Al) | Balance | Balance | Balance | Balance |

Mechanical Properties (Typical in T6 or H321 Tempers)

| Property | 5083-H321 | 5052-H32 | 6061-T6 | 6082-T6 |

|---|---|---|---|---|

| Tensile Strength (MPa) | 300 – 350 | 228 – 271 | 310 – 350 | 280 – 340 |

| Yield Strength (MPa) | 145 – 215 | 103 – 138 | 270 – 300 | 240 – 300 |

| Elongation (%) | 10 – 18 | 10 – 15 | 8 – 12 | 8 – 12 |

| Hardness (Brinell) | 75 – 95 | 60 – 75 | 95 – 115 | 95 – 135 |

| Density (g/cm³) | 2.66 | 2.68 | 2.70 | 2.70 |

Manufacturing Process

Extrusion: The primary manufacturing method where heated billets are pushed through dies to form rectangular tubular profiles with uniform wall thickness and excellent surface finish.

Seamless Tube Forming: For applications requiring superior strength and surface integrity.

Heat Treatment: Solution heat treatment and artificial aging (e.g., T6) applied to achieve the desired mechanical properties and corrosion resistance.

Surface Finishing: Mill finish common; anodized or powder-coated finishes offered for enhanced corrosion resistance and aesthetics.

Cutting & Machining: Supplied in stock or custom lengths; fabrication includes cutting, welding, and machining according to marine industry standards.

Typical Marine Applications

Structural framework and support members for ship hulls, decks, and superstructures

Offshore platform supports, safety railings, and walkway framing

Marine equipment housing, racks, and protective enclosures

Coastal infrastructure such as piers, docks, and bridges exposed to salt spray

Railings, ladders, and safety barriers in marine and offshore environments

Custom marine fabrication requiring corrosion-resistant, rigid, and lightweight profiles

Advantages Over Other Materials

| Feature | Marine Aluminum Rectangular Tubes | Steel Rectangular Tubes | Stainless Steel Rectangular Tubes |

|---|---|---|---|

| Corrosion Resistance | Excellent, especially in marine environments | Requires coatings to prevent rust | Very good but much heavier and costlier |

| Weight | Lightweight (~2.66 g/cm³) | Heavy (~7.85 g/cm³) | Heavy (~7.7–8.0 g/cm³) |

| Maintenance | Minimal, naturally corrosion-resistant | High due to rust without coatings | Moderate maintenance |

| Fabrication Ease | Easy welding, cutting, machining | Requires robust tools and equipment | Difficult and expensive |

| Cost | Moderate upfront cost | Lower material cost, higher lifetime costs | High initial and upkeep cost |

Maintenance Guidelines

Rinse regularly with fresh water to remove salt and marine deposits.

Avoid abrasive cleaning methods; opt for mild detergents and soft brushes.

Inspect cut edges, welds, and fasteners for early signs of corrosion or damage.

Apply anodizing or marine-grade protective coatings in highly corrosive environments.

Use electrical isolation techniques where aluminum interfaces with dissimilar metals to prevent galvanic corrosion.

Marine Grade Aluminum Rectangular Tubes offer unmatched corrosion resistance, structural strength, and design flexibility, making them key structural components in marine and offshore engineering. Their lightweight nature and durability enable efficient, long-lasting marine structures and equipment.

For custom alloy selection, sizing, and expert technical advice, contact our marine aluminum specialists to assist you in specifying the ideal rectangular aluminum tubes for your project needs.