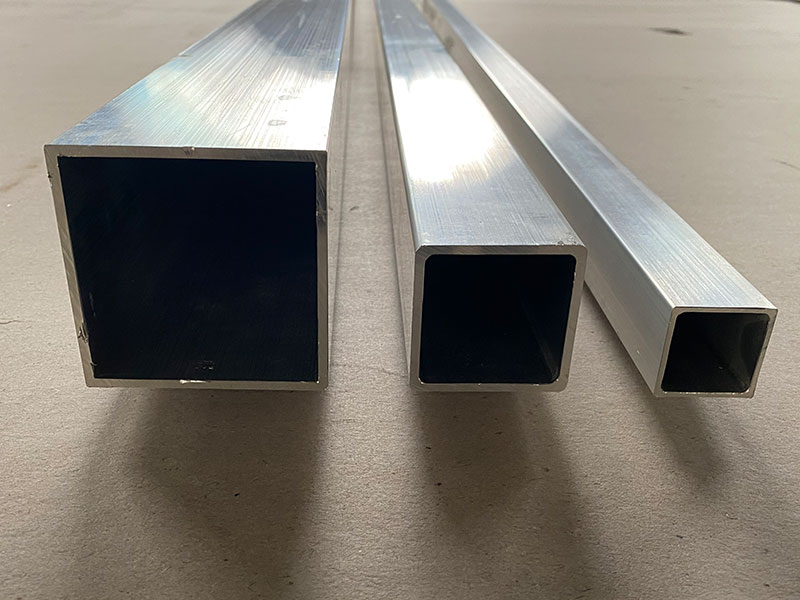

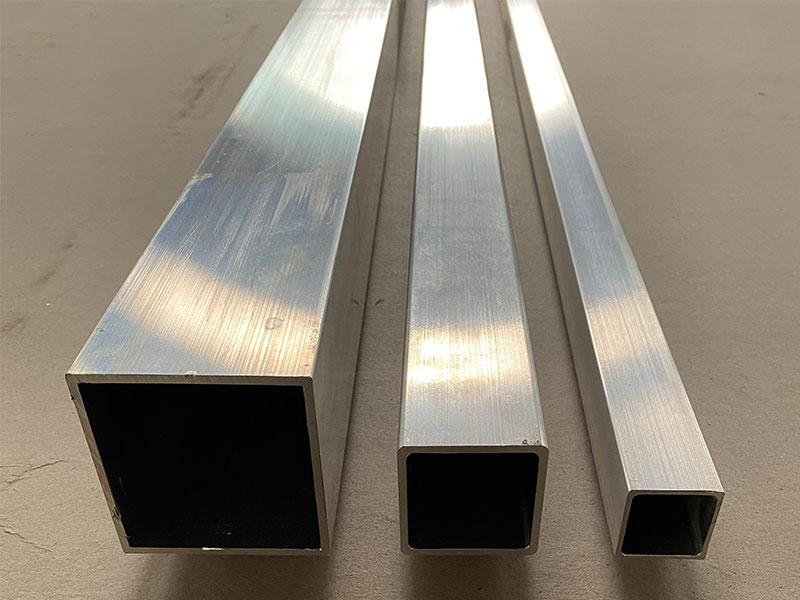

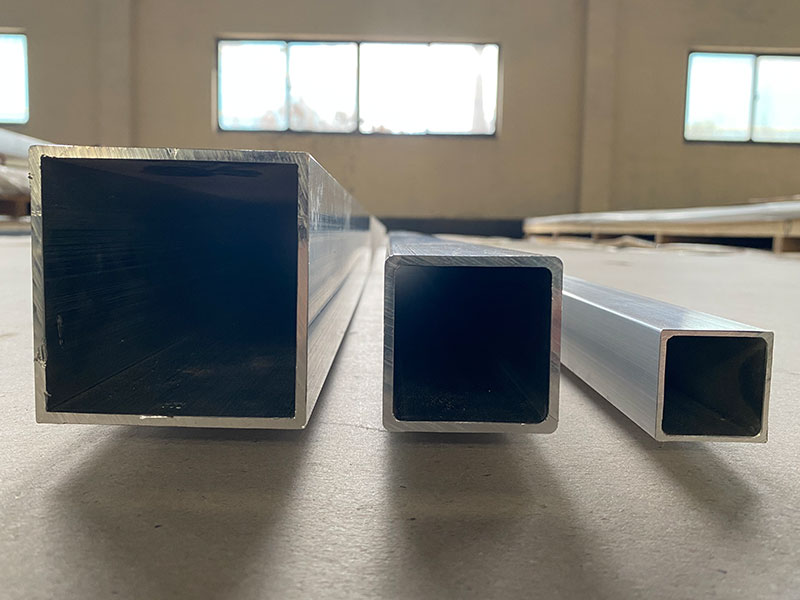

Marine Grade Aluminum Square Tubes are engineered aluminum structural profiles designed specifically to perform in harsh marine and offshore environments. Manufactured from high-quality marine aluminum alloys, these square tubes combine exceptional corrosion resistance with durability and lightweight characteristics. Their square cross-section provides excellent strength and versatility, making them indispensable components in shipbuilding, offshore platforms, coastal construction, and marine equipment manufacturing.

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres. Their square profile offers balanced strength in multiple directions and convenient mounting or joining surfaces, enabling ease of integration into marine frameworks and mechanical assemblies.

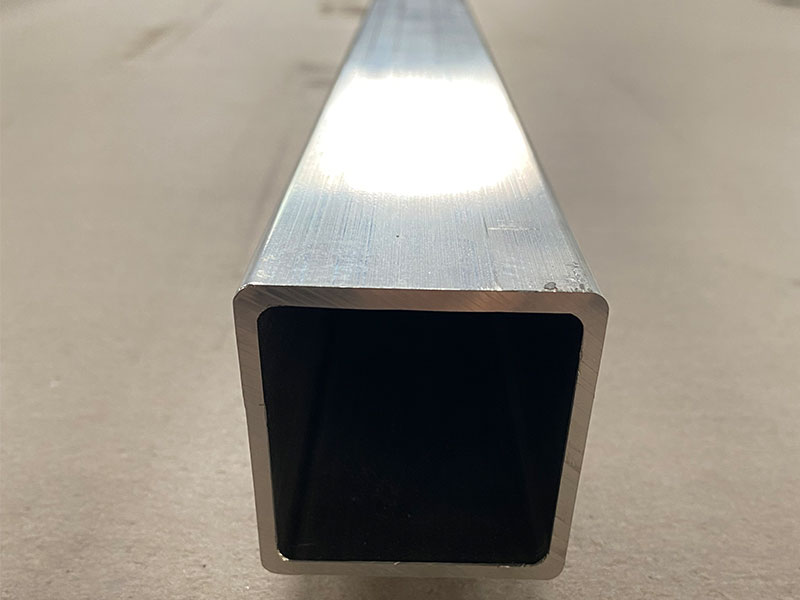

Produced primarily by precision extrusion or seamless tube rolling methods, these square tubes maintain tight dimensional tolerances, uniform wall thickness, and smooth surface finishes. They are supplied in a variety of sizes, thicknesses, and lengths to meet specific project demands.

Common Marine Aluminum Alloys Used for Square Tubes

| Alloy | Key Chemical Characteristics | Marine Advantages |

|---|---|---|

| 5083 | Mg 4.0-4.9%, excellent corrosion resistance | High durability in seawater, structural strength |

| 5052 | Mg 2.2-2.8%, great formability and corrosion resistance | Suitable for light structural and fabricated parts |

| 6061 | Mg 0.8-1.2%, Si 0.4-0.8%, heat-treatable for strength | High strength, weldability, and anodizing option |

| 6082 | Mg 0.6-1.2%, Si 0.7-1.3%, excellent mechanical properties | Stronger alloy with good corrosion resistance |

Chemical Composition Overview

| Element | 5083 (%) | 5052 (%) | 6061 (%) | 6082 (%) |

|---|---|---|---|---|

| Magnesium (Mg) | 4.0 – 4.9 | 2.2 – 2.8 | 0.8 – 1.2 | 0.6 – 1.2 |

| Silicon (Si) | ≤ 0.4 | ≤ 0.25 | 0.4 – 0.8 | 0.7 – 1.3 |

| Chromium (Cr) | 0.05 – 0.25 | 0.15 – 0.35 | 0.04 – 0.35 | 0.25 – 0.45 |

| Copper (Cu) | ≤ 0.1 | ≤ 0.1 | 0.15 – 0.4 | ≤ 0.1 |

| Iron (Fe) | ≤ 0.4 | ≤ 0.4 | ≤ 0.7 | ≤ 0.5 |

| Manganese (Mn) | 0.4 – 1.0 | ≤ 0.1 | ≤ 0.15 | 0.4 – 1.0 |

| Zinc (Zn) | ≤ 0.25 | ≤ 0.1 | ≤ 0.25 | ≤ 0.2 |

| Titanium (Ti) | ≤ 0.15 | ≤ 0.03 | ≤ 0.15 | ≤ 0.1 |

| Aluminum (Al) | Balance | Balance | Balance | Balance |

Mechanical Properties (Representative Values)

| Property | 5083-H321 | 5052-H32 | 6061-T6 | 6082-T6 |

|---|---|---|---|---|

| Tensile Strength (MPa) | 300 – 350 | 228 – 271 | 310 – 350 | 280 – 340 |

| Yield Strength (MPa) | 145 – 215 | 103 – 138 | 270 – 300 | 240 – 300 |

| Elongation (%) | 10 – 18 | 10 – 15 | 8 – 12 | 8 – 12 |

| Hardness (Brinell) | 75 – 95 | 60 – 75 | 95 – 115 | 95 – 135 |

| Density (g/cm³) | 2.66 | 2.68 | 2.70 | 2.70 |

Manufacturing Methods

Extrusion: The predominant method for producing marine aluminum square tubes, ensuring precise cross-section, uniform wall thickness, and superior surface finish.

Seamless Tube Forming: In select cases, seamless forming is used for enhanced strength and corrosion resistance.

Heat Treatment: Appropriate tempering (e.g., T6 for 6061) improves the mechanical properties and durability.

Surface Finish: Standard mill finish is common; anodizing or marine-grade painting options are available to enhance corrosion resistance and aesthetics.

Typical Marine Applications

Structural beams and framing components in shipbuilding and offshore platforms

Handrails, ladders, and guardrails for marine vessels and coastal facilities

Electrical cable trays and conduit supports exposed to marine atmosphere

Mounting frameworks for marine navigation and communication systems

Fabrication of lightweight, corrosion-resistant equipment housings and enclosures

Support structures in docks, piers, and marina infrastructure

Advantages Over Traditional Materials

| Feature | Marine Aluminum Square Tubes | Steel Square Tubes | Stainless Steel Square Tubes |

|---|---|---|---|

| Corrosion Resistance | Excellent, inherent aluminum oxide layer | Needs coatings or galvanizing | Very good but heavier and costly |

| Weight | Lightweight (~2.66 g/cm³) | Heavy (~7.85 g/cm³) | Heavy (~7.7–8.0 g/cm³) |

| Maintenance | Low, typically no painting needed | High maintenance due to rust | Medium maintenance |

| Fabrication Ease | Easy to weld, cut, and form | Requires heavier equipment | More difficult and expensive |

| Cost | Moderate upfront cost | Lower initial cost; higher lifecycle cost | Expensive upfront investment |

Maintenance Recommendations

Flush regularly with fresh water to remove salt deposits.

Use mild detergents and avoid abrasive tools to preserve finish.

Inspect welding joints and fasteners for early signs of corrosion or wear.

Apply anodizing or coating in highly corrosive areas for added protection.

Ensure electrical and mechanical isolation from dissimilar metals to reduce galvanic corrosion.

Marine Grade Aluminum Square Tubes provide a superior solution for lightweight, strong, and corrosion-resistant marine structural applications. Their durability in harsh saltwater environments combined with fabrication versatility makes them a vital material for modern marine construction and equipment manufacturing.

For tailored specifications, alloy recommendations, or project consultation, please contact our marine aluminum experts who are ready to support your specific marine-grade aluminum tubing needs.