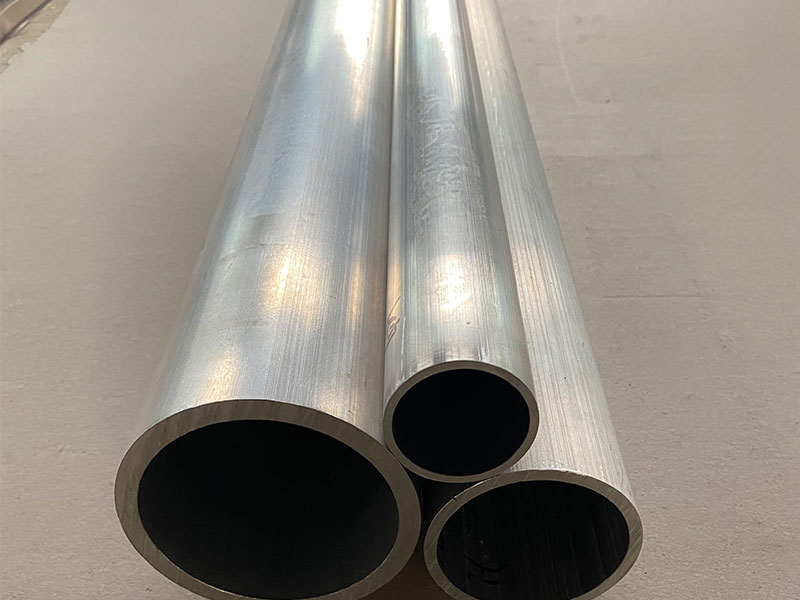

Marine Grade Aluminum Round Tubes are essential tubular structural components purpose-built to withstand the aggressive conditions of marine and offshore environments. Engineered from high-performance marine aluminum alloys, these round tubes combine excellent corrosion resistance, superior strength-to-weight ratios, and versatile fabrication capabilities. They are widely employed in shipbuilding, offshore platforms, coastal infrastructure, and diverse marine equipment manufacturing, providing durable and lightweight solutions essential for longevity and reliability in saltwater conditions.

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation. The round tubular profile offers excellent geometric efficiency, allowing maximum structural strength and stiffness with minimal material and weight.

Produced primarily by precision extrusion or seamless tube forming processes, these aluminum tubes feature consistent dimensional tolerances, smooth surface finish, and customizable wall thicknesses and diameters, making them an ideal choice for structural, mechanical, and aesthetic marine applications.

Marine Aluminum Alloys Used for Round Tubes

| Alloy | Key Characteristics | Typical Applications |

|---|---|---|

| 5083 | Mg 4.0-4.9%, excellent corrosion resistance, medium strength | Hull structures, offshore platform tubing |

| 5052 | Mg 2.2-2.8%, excellent formability and corrosion resistance | Equipment tubing, lightweight framing |

| 6061 | Heat treatable, good strength and machinability | Load bearing tubes, machined marine fittings |

| 6082 | High strength 6xxx series, good corrosion and toughness | Shafts, masts, structural marine tubing |

Chemical Composition (Representative)

| Element | 5083 (%) | 5052 (%) | 6061 (%) | 6082 (%) |

|---|---|---|---|---|

| Magnesium (Mg) | 4.0 – 4.9 | 2.2 – 2.8 | 0.8 – 1.2 | 0.6 – 1.2 |

| Silicon (Si) | ≤ 0.4 | ≤ 0.25 | 0.4 – 0.8 | 0.7 – 1.3 |

| Chromium (Cr) | 0.05 – 0.25 | 0.15 – 0.35 | 0.04 – 0.35 | 0.25 – 0.45 |

| Copper (Cu) | ≤ 0.1 | ≤ 0.1 | 0.15 – 0.4 | ≤ 0.1 |

| Iron (Fe) | ≤ 0.4 | ≤ 0.4 | ≤ 0.7 | ≤ 0.5 |

| Manganese (Mn) | 0.4 – 1.0 | ≤ 0.1 | ≤ 0.15 | 0.4 – 1.0 |

| Zinc (Zn) | ≤ 0.25 | ≤ 0.1 | ≤ 0.25 | ≤ 0.2 |

| Titanium (Ti) | ≤ 0.15 | ≤ 0.03 | ≤ 0.15 | ≤ 0.1 |

| Aluminum (Al) | Balance | Balance | Balance | Balance |

Mechanical Properties (Typical in T6 or H321 Tempers)

| Property | 5083-H321 | 5052-H32 | 6061-T6 | 6082-T6 |

|---|---|---|---|---|

| Tensile Strength (MPa) | 300 – 350 | 228 – 271 | 310 – 350 | 280 – 340 |

| Yield Strength (MPa) | 145 – 215 | 103 – 138 | 270 – 300 | 240 – 300 |

| Elongation (%) | 10 – 18 | 10 – 15 | 8 – 12 | 8 – 12 |

| Hardness (Brinell) | 75 – 95 | 60 – 75 | 95 – 115 | 95 – 135 |

| Density (g/cm³) | 2.66 | 2.68 | 2.70 | 2.70 |

Manufacturing Process

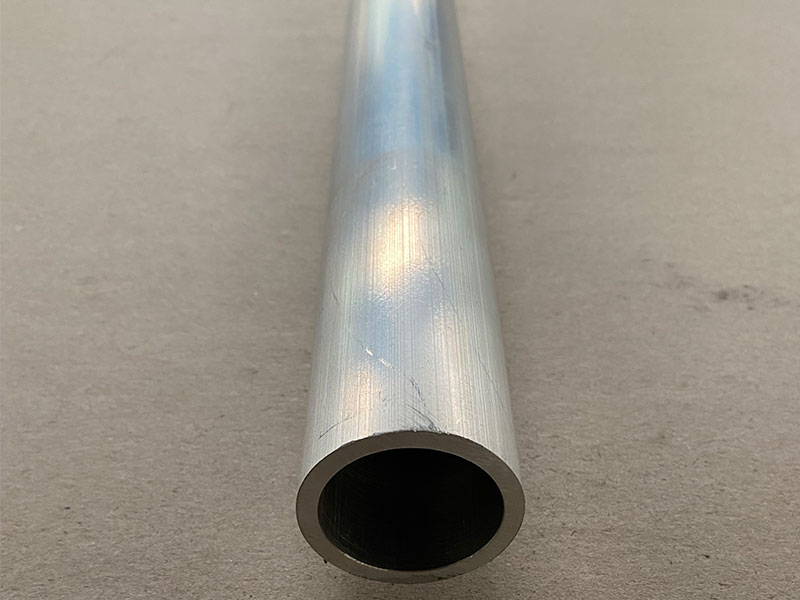

Extrusion: The primary manufacturing method where heated billets are forced through dies, forming hollow round tubes with precise diameter and wall thickness.

Seamless Tube Forming: In some cases, seamless tubes are formed for enhanced mechanical properties and surface quality.

Heat Treatment: Solution heat treatment followed by artificial aging (T6 temper) optimizes mechanical strength.

Finishing: Standard mill finishes are common, with options for anodizing or powder coating to enhance corrosion resistance and aesthetics.

Cutting & Machining: Tubes are supplied in standard lengths or cut-to-size, ready for machining, welding, or assembly.

Typical Marine Applications

Structural supports and tubing for ship hulls, decks, and superstructures.

Offshore oil and gas platform support struts, risers, and walkways.

Lightweight masts, boom arms, and rigging components on vessels.

Hydraulic and pneumatic cylinder tubes for marine machinery.

Handrails, guardrails, and safety barriers in marine and coastal facilities.

Marine equipment enclosures, racks, and tubular frameworks.

Advantages of Marine Aluminum Round Tubes

Optimized Strength-to-Weight: Delivers excellent stiffness and strength while reducing overall weight compared to steel.

Outstanding Corrosion Resistance: Protects against seawater-induced pitting, crevice corrosion, and oxidation.

Excellent Fabrication: Easily welded, formed, machined, and joined with standard marine industry tools.

Longevity: Resistant to marine environment degradation, reducing maintenance and lifetime costs.

Sustainability: Aluminum is fully recyclable, enabling environmentally friendly marine engineering solutions.

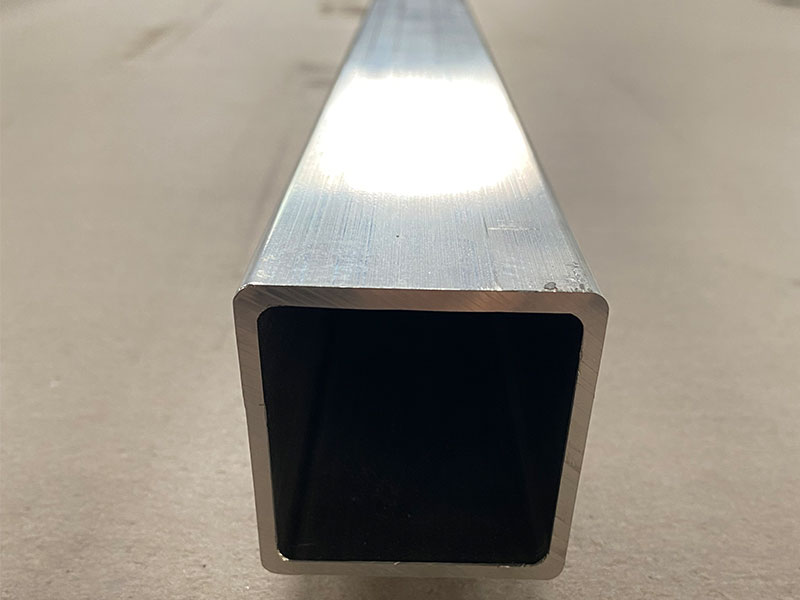

Versatility: Suitable for structural, mechanical, and aesthetic marine applications due to customizable dimensions.

Maintenance Guidelines

Routine Cleaning: Regular washing with fresh water prevents salt accumulation and corrosive buildup.

Gentle Cleaning Agents: Use mild detergents and soft brushes or cloths to avoid surface damage.

Regular Inspection: Monitor for signs of abrasions, dents, or corrosion—especially near welds and joints.

Protective Coatings: Anodizing or powder coating enhances protection in highly aggressive or exposed marine locations.

Isolation Practices: Insulate aluminum tubes from dissimilar metals to avoid galvanic corrosion.

Marine Grade Aluminum Round Tubes offer marine industry professionals a powerful combination of corrosion resistance, strength, lightness, and fabrication flexibility. From structural supports to machinery components, these tubes fulfill critical roles in marine and offshore environments characterized by saltwater exposure and mechanical stresses.

For tailored technical advice, custom sizing, or ordering information, contact our marine aluminum specialists who will assist in selecting the best marine aluminum round tubes for your project’s needs.