Custom Marine Grade Aluminum Profile Tubes represent a sophisticated and highly versatile solution tailored to meet the unique demands of modern marine, offshore, and coastal construction projects. Combining the superior corrosion resistance and lightweight properties of marine-grade aluminum alloys with the design flexibility of custom extrusions, these profile tubes enable engineers and fabricators to optimize structural performance, enhance longevity, and reduce overall weight in challenging saltwater environments.

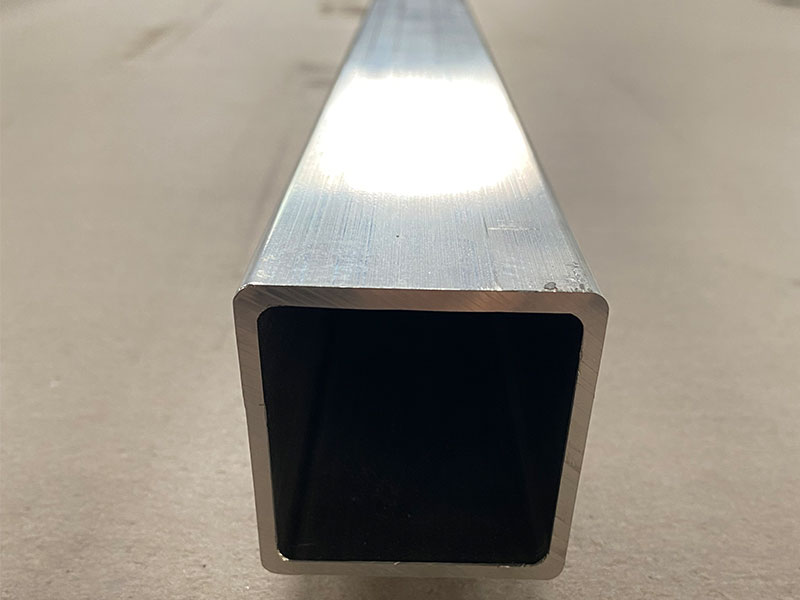

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082. These alloys are engineered to withstand the corrosive effects of seawater and salt-laden atmospheres while maintaining excellent mechanical strength and weldability. Unlike standard tubular profiles, “custom” profiles can possess any shape or cross-section—ranging from rectangular, square, circular, Z-shaped, T-shaped, to uniquely engineered profiles tailored precisely to project specifications.

The ability to design and produce profile tubes with tailored geometries maximizes structural and functional benefits such as optimized load distribution, improved hydrodynamics, enhanced assembly ease, and integration with auxiliary marine equipment.

Features and Advantages

| Feature | Description | Benefit |

|---|---|---|

| Marine-Grade Aluminum Alloys | 5xxx (5083, 5052) and 6xxx (6061, 6082) series with proven marine corrosion resistance | Longevity and reliability in aggressive saltwater environments |

| Customizable Cross-Sections | Fully adaptable designs including complex geometries and variable wall thicknesses | Optimizes strength, weight, and design integration |

| Lightweight Properties | Aluminum density ~2.66–2.70 g/cm³, significantly lighter than steel | Enhanced fuel efficiency and ease of handling |

| High Strength and Rigidity | Alloy-specific mechanical properties address application demands | Structural integrity and durability under load |

| Excellent Weldability & Machinability | Compatible with marine fabrication standards allowing cutting, welding, drilling, and forming | Facilitates efficient manufacturing and onsite modifications |

| Corrosion Resistance | Naturally forming oxide layer in marine alloys coupled with potential surface treatments | Reduces maintenance and extends service life |

| Versatility | Suitable for structural members, fluid conduits, protective covers, and decorative elements | Wide range of marine construction and engineering solutions |

Common Marine Aluminum Alloys Utilized

| Alloy | Characteristics | Optimal Applications |

|---|---|---|

| 5083 | High magnesium content (~4.0-4.9%), excellent corrosion resistance | Hull framing, offshore structural members |

| 5052 | Moderate strength with notable workability and corrosion resistance | Equipment enclosures, cabinetry |

| 6061 | Heat-treatable, versatile strength and corrosion resistance | Structural supports, hardware |

| 6082 | High strength 6xxx alloy with good durability | Heavy load components, tubes |

Manufacturing Process

Design & Engineering: Customer-supplied CAD drawings facilitate production of precise dies and tooling for extrusion.

Extrusion: Aluminum billets heated and pushed through shaped dies form consistent, complex profiles per specifications.

Heat Treatment: Solution heat treatment and artificial aging (typically T6 temper) optimize strength.

Finishing: Profiles receive mill, anodized, powder-coated, or painted surface finishes tailored to environmental conditions and customer aesthetics.

Cutting & Fabrication: Profiles are custom cut, drilled, welded, and formed to meet final assembly requirements.

Typical Marine Applications

Structural frameworks for ships, yachts, and offshore installations

Custom piping and conduit protection sleeves resistant to marine corrosion

Railings, ladders, and safety barriers with optimized profiles for strength and grip

Architectural cladding and decorative marine facade elements

Equipment racks, mounting brackets, and marine hardware components

Hydrodynamic and aerodynamic components tailored for vessels and rigs

Benefits Over Standard Tubular Products

| Criterion | Custom Marine Aluminum Profile Tubes | Standard Tubular Sections | Steel Tubular Sections |

|---|---|---|---|

| Design Flexibility | Completely adaptable to design needs | Limited sizes and shapes | Limited shapes, heavy weight |

| Corrosion Resistance | Superior, alloy-based protection | Less corrosion resistant alloy | Requires coatings, heavy corrosion risk |

| Weight | Lightweight; reduces overall mass | Moderate | Heavy, increases vessel weight |

| Fabrication Ease | Easily welded and modified on site | Standard fabrication processes | Fabrication more energy-intensive |

| Lifecycle Cost | Reduced maintenance, longer lifespan | Average | Higher lifetime costs due to corrosion |

Maintenance Guidelines

Cleaning: Rinse regularly with fresh water to clear salt and marine deposits.

Avoid Harsh Chemicals: Use mild detergents and soft brushes for cleaning anodized or coated surfaces to prevent damage.

Surface Inspection: Periodically inspect for mechanical damage, corrosion initiation points, or welding integrity issues.

Apply Protective Coatings: Anodizing or marine-grade fluid-applied coatings can be used to further deter corrosion.

Proper Handling & Storage: Store in dry, covered locations and insulate from contact with dissimilar metals to prevent galvanic corrosion.

Custom Marine Grade Aluminum Profile Tubes provide marine and offshore engineers with a high-performance, corrosion-resistant, and lightweight solution, uniquely tailored to meet any design challenge posed by the marine environment. Their versatility and robustness enable innovative engineering approaches that enhance durability, reduce weight, and optimize fabrication processes.

For expert consultation, custom profile design services, and bulk order quotes, contact our marine aluminum specialists who will guide you to the perfect tailored profile tubes for your specific marine project requirements