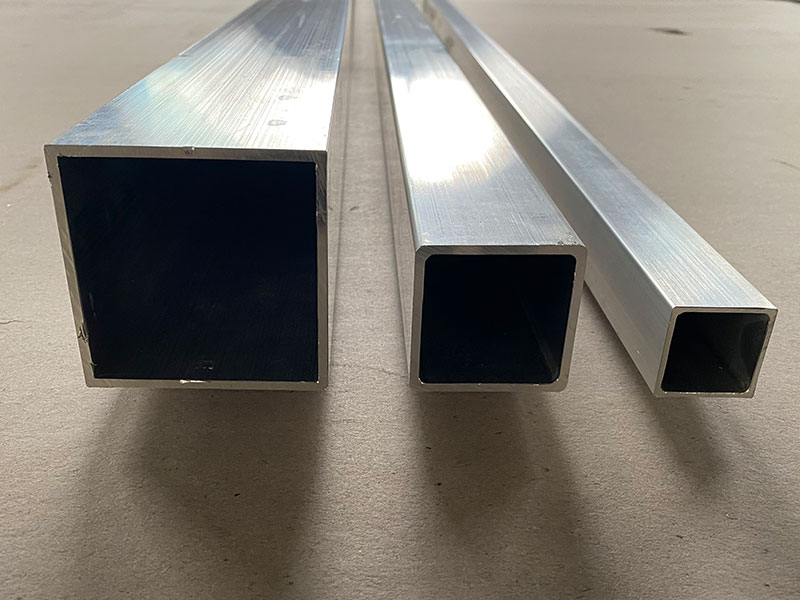

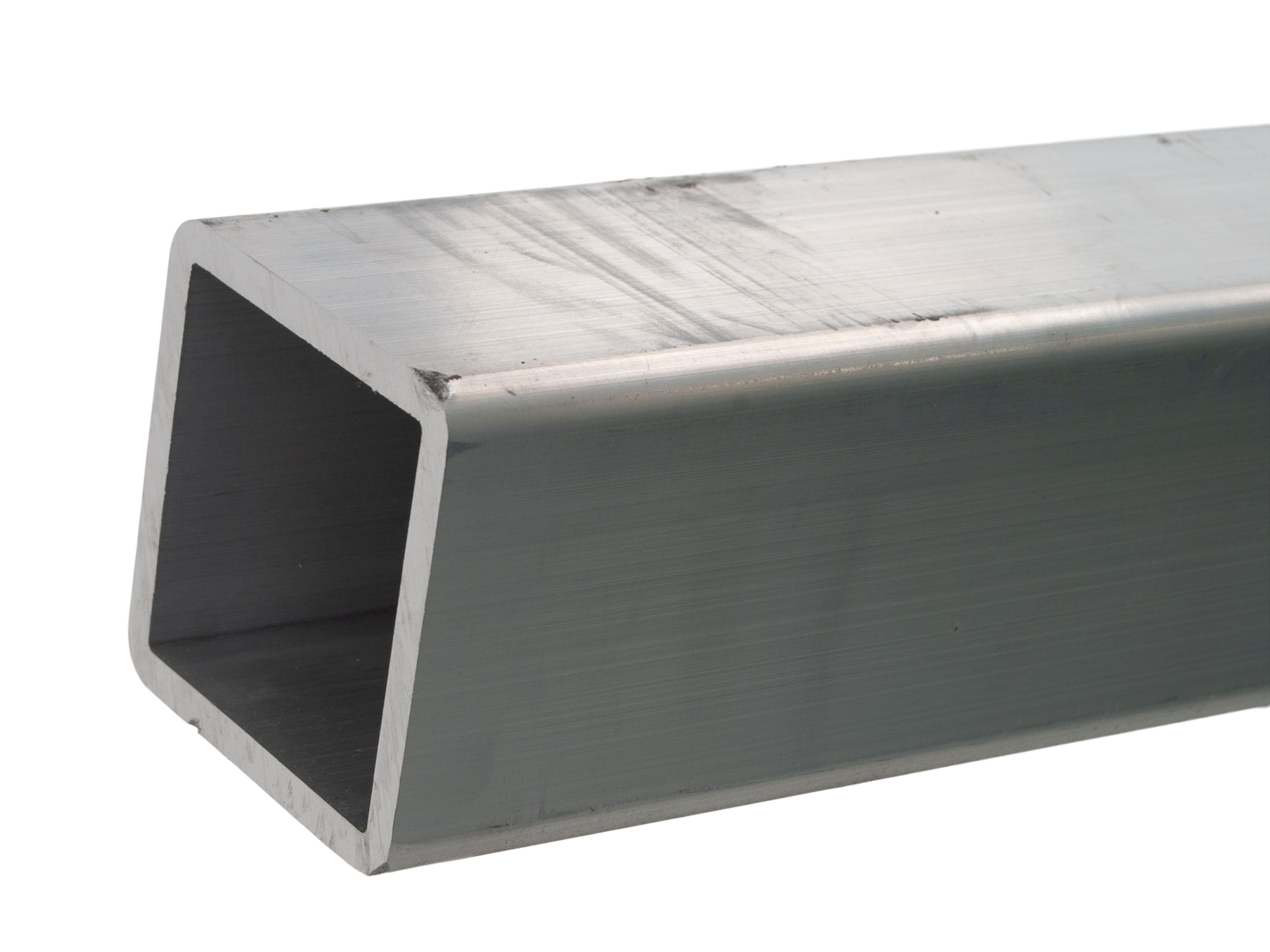

6061 Marine Aluminum Square Tubes for Yacht Construction

In the realm of yacht construction, materials play a pivotal role in defining vessel performance, durability, and aesthetics. One outstanding material that increasingly gains favor among naval architects and marine engineers is 6061 Marine Aluminum Square Tubes. Distinguished by its blend of strength, corrosion resistance, and workability, this alloy has become a component in modern yacht frameworks.

Why 6061 Aluminum Square Tubes for Marine Applications?

Marine environments are exceptionally challenging for construction materials due to constant exposure to saltwater, UV radiation, and mechanical stresses from sea conditions. 6061 aluminum square tubes offer a unique balance of properties tailored to combat these stressors efficiently.

- Excellent Corrosion Resistance: The high magnesium and silicon content in 6061 confer natural resistance to pitting and galvanic corrosion.

- Structural Integrity: The alloy and fabrication process ensure optimal yield and tensile strength, adequate for structural yacht components subjected to winding loads and vibrations.

- Fabrication Ease: Good weldability and machinability make 6061 the favorable choice for intricate yacht designs.

- Marine-Specific Heat Treatments: Adjusting temper operations gives this alloy an enhanced marine-ready durability.

Technical Parameters for Yacht Construction

When specifying 6061 marine aluminum square tubes, these typical technical parameters guide purchase and construction compliance:

| Parameter | Typical Value |

|---|---|

| Alloy Grade | 6061 (Marine Grade) |

| Temper | T6, T651 (solution heat-treated + artificially aged for strength) |

| Yield Strength | 240 MPa (min) |

| Tensile Strength | 290–310 MPa |

| Elongation at Break | ≥12% |

| Density | 2.70 g/cm³ |

| Thermal Conductivity | ~167 W/m·K at 25°C |

| Modulus of Elasticity | ~69 GPa |

| Typical Dimension Range | 10 x 10 mm up to 200 x 200 mm square tubes |

| Wall Thickness Range | 1.0 mm to 12 mm |

Implementation and Compliance Standards

Strict adherence to international marine aluminum standards not only guarantees performance but ensures manufacturers meet code classification requirements for use in yachts.

- ASTM B221: Standard specification for aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes.

- ABS Rules for Building and Classing Aluminum Vessels covers structural design using 6061 alloys ensuring safe and certified yacht manufacture.

- ISO 6361: The aluminum and aluminum alloys standard outlines chemical composition and mechanical tests.

- Marine Grade Tempering: Typically T6 or T651 temper is required which involves solution heat treatment, quenching, and artificial aging resulting in precipitation hardening.

Alloy Tempering: Impact on Mechanical and Corrosion Behavior

6061 alloy in T6 or T651 temper states is most common in marine square tubes.

- In the T6 temper, the aluminum is subjected to solution heat treatment followed by quenching, and then artificially aged to enhance strength.

- The T651 temper incorporates a minor stress-relief step after quenching without significantly sacrificing tensile strength.

These processes increase hardness and yield strength to ideal levels yet retain ductility. The tempering distinctly enhances resistance to mechanical fatigue caused by wave motion and yacht vibration.

Chemical Composition Breakdown

the chemical makeup reveals why 6061 excels in marine conditions:

| Element | Content Range (%) |

|---|---|

| Silicon (Si) | 0.4 – 0.8 |

| Iron (Fe) | ≤ 0.7 |

| Copper (Cu) | 0.15 – 0.4 |

| Manganese (Mn) | ≤ 0.15 |

| Magnesium (Mg) | 0.8 – 1.2 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others | ≤ 0.15 collectively |

| Aluminum (Al) | Balance (typically ≥ 97.9) |

The balanced magnesium and silicon elemental synergy result in Mg2Si precipitates during heat treatment, which are vital for strengthening. Chromium’s trace presence improves corrosion resistance by enhancing the stability of the protective oxide film.

Beyond composition and tempering, the square tube geometry itself impacts yacht frame design markedly:

- Increased Moment of Inertia: Square tubes provide a uniform distribution of stress compared to circular tubes, enhancing resistance to torsional and bending loads.

- Ease of Joining: Flat surfaces simplify welding and fastening operations integral in yacht skeletons’ modular design.

- Aesthetic Appeal: Modern yacht architecture favors clean profiles; square tubes align aesthetically without sacrificing strength or corrosion resistance.

Hence, using 6061 marine aluminum square tubes integrates not only durability and compliance but cutting-edge engineering principles balancing form and functionality.

Brief yet functionally potent, 6061 marine aluminum square tubes embody one of the finest materials adapted for yacht construction. They jointly provide robust mechanical qualities, formidable corrosion resistance via alloy composition and tempering, with dimensional versatility governed by rigorous marine standards. From marine architects to engineers, these materials represent a trusted maritime engineering solution grounded in avionics-grade precision now mobilized for ocean traversing luxury and endurance.

By selecting 6061 aluminum square tubes fabricated with precise temper treatments such as T6 or T651 and adhering strictly to ASTM B221 or similar certification processes, yacht builders can confidently achieve structural excellence and increased vessel life span — proving this choice impeccable in marine material craftsmanship.

Interested in sourcing high-grade 6061 marine aluminum square tubes? Contact our team to ensure competitive pricing, certifications, and custom dimension support, empowering your next yacht build with engineers' first choice material confidence.

Related Products

6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsRelated Blog

6061 Marine Aluminum Tubes for Custom Boat Frame Solutions

When it comes to constructing custom boat frames, marine-grade materials play a crucial role in ensuring longevity, safety, and performance. Among the vast selection of marine-grade metals.

View Details6061 Marine Aluminum Square Tubes for Yacht Construction

In the realm of yacht construction, materials play a pivotal role in defining vessel performance, durability, and aesthetics.

View Details6061 Marine Aluminum Tubes for Custom Marine Construction

When it comes to building robust, lightweight, and corrosion-resistant structures for marine applications, 6061 Marine Aluminum Tubes unquestionably lead the pack.

View Details6061 Marine Aluminum Tubes for Marine Engineering Projects

Marine engineering demands materials that combine exceptional strength, corrosion resistance, and versatility for reliable performance in harsh seawater environments.

View Details

Leave a Message