6061 Marine Aluminum Tubes for Custom Marine Construction

When it comes to building robust, lightweight, and corrosion-resistant structures for marine applications, 6061 Marine Aluminum Tubes unquestionably lead the pack. Tailored specifically for custom marine construction, these tubes offer a blend of mechanical performance and marine-grade resilience that's hard to beat.

The Distinctive Edge of 6061 Marine Aluminum Tubes in Marine Construction

Marine environments demand materials that resist saltwater corrosion, UV degradation, and mechanical wear, while providing structural integrity under dynamic loads—from hulls to masts and decking systems. Unlike traditional metals or composite alternatives, 6061 marine aluminum tubes combine the structural advantage of high strength-to-weight ratio with exceptional corrosion resistance, due largely to their carefully engineered alloy composition enhanced through tempering.

What Sets 6061 Aluminum Tubes Apart?

- Tailor-Made for Marine Conditions: Unlike standard 6061 aluminum, marine-grade tubes comply with tighter standards ensuring minimal inclusion of elements harmful in a saltwater environment.

- Enhanced Fatigue and Impact Resistance: Ideal for load-bearing marine components subjected to constant motion and vibrations.

- Ease of Fabrication and Welding: Enables custom shapes ensuring optimal hydrodynamics and design complexity for custom marine architecture.

Technical Parameters You Need to Know

Specifications for 6061 marine aluminum tubes directly influence their suitability for custom marine fabrication:

| Parameter | Typical Value |

|---|---|

| Alloy | 6061 |

| Temper | T6 |

| Tensile Strength | 290 - 310 MPa |

| Yield Strength | 240 MPa |

| Elongation at Break | 10-12% |

| Density | 2.70 g/cm³ |

| Corrosion Resistance | Excellent in marine environments |

| Hardness (Brinell) | 95-107 HB |

| Thermal Conductivity | 167 W/m.K |

Temper T6—the Aluminum Marine Tubes Stein

The T6 temper in 6061 tubes means that the alloy has been solution heat-treated and artificially aged. This process significantly enhances tensile strength, for handling dynamic loads common in marine constructs, such as masts or tubular frame supports.

- Solution Heat Treatment: Heats the aluminum alloy above 530°C, dissolving the soluble phases.

- Quenching: Rapid cooling then traps those dissolved phases in a supersaturated solution.

This precise engineering of the microstructure means that marine aluminum tubes show superior toughness without compromising any corrosion resistance advantage, crucial for saltwater durability.

Implementation Standards That Validate Marine Aluminum Quality

Reliable structural material choices demand compliance with recognized standards. For 6061 marine aluminum tubes, the core standards your fabrication process and suppliers should conform to include:

- ASTM B210: Covers “Aluminum and Aluminum-Alloy Drawn Seamless Tubes,” specifying dimensional tolerances, mechanical properties, and surface finish.

- AMS-QQ-A-200/11: The aerospace material specification overlapping marine applications ensuring rigorous quality control for marine dielectric and environmental resistance.

- ISO 6361 (Aluminum Alloys - Drawn seamless tubes): Globally recognized marks relevant to marine manufacturing.

These standards guarantee enabling engineers and builders alike to trust 6061 tubes with stability and longevity in complex marine structures.

Chemical Composition Tailored for Marine Durability

At the atomic level, durability in marine conditions boils down to precise chemical alloying. Here is the typical 6061 marine aluminum tube chemical composition that naturalizes corrosion resistance while improving mechanical integrity:

| Element | Percentage (%) |

|---|---|

| Silicon (Si) | 0.4 - 0.8 |

| Iron (Fe) | ≤ 0.7 |

| Copper (Cu) | 0.15 - 0.4 |

| Manganese (Mn) | ≤ 0.15 |

| Magnesium (Mg) | 0.8 - 1.2 |

| Chromium (Cr) | 0.04 - 0.35 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance |

Why This Specific Alloy Balance for Marine Use?

- Magnesium (Mg) & Silicon (Si): Form Mg2Si, the strengthening phase crucial in T6 temper.

- Chromium (Cr): Acts as a grain refiner, enhancing corrosion resistance and mechanical toughness.

- Iron (Fe) & Copper (Cu): Maintained at low levels to prevent galvanic corrosion—a common concern in marine salinity.

- Titanium (Ti): Minimizes grain growth during processing, promotes achromatic solidness.

Thus, 6061 alloy balances mechanical prowess with corrosion endurance ideally fitted for variable saltwater exposure zones.

Why Choose 6061 Marine Aluminum Tubes for Your Custom Marine Project?

- Lightweight Yet Extremely Strong: Relative to steel, less fuel consumption and easier handling.

- Resistant to Salt Water and Atmospheric Corrosion: Lengthens service lifespan without coating dependencies.

- Versatility in Custom Fabrication: Can be drawn, bent, welded, or machined into any shape integral to futuristic marine designs.

- Aesthetic Appeal and Sustainability: Natural metallic finish resists fading while being recyclable aligns with modern eco-conscious marine efforts.

Final Thoughts

For marine architects, builders, and OEMs tackling custom hulls, supports, railings, or propulsion framing—6061 marine aluminum tubes provide a compelling and engineered solution driven by science and certified standards. Their technical parameters, tempering processes, and optimized chemical profiles make them uniquely suited to endure the fast-moving and harsh marine environment.

Embrace 6061 marine aluminum tubing as your material of choice—where creativity, performance, safety, and longevity seamlessly sail along.

Ready to take your marine construction projects to uncharted strength and durability? Contact our experienced team today to discover the full capabilities of 6061 Marine Aluminum Tubes tailored to your bespoke maritime needs!

Related Products

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

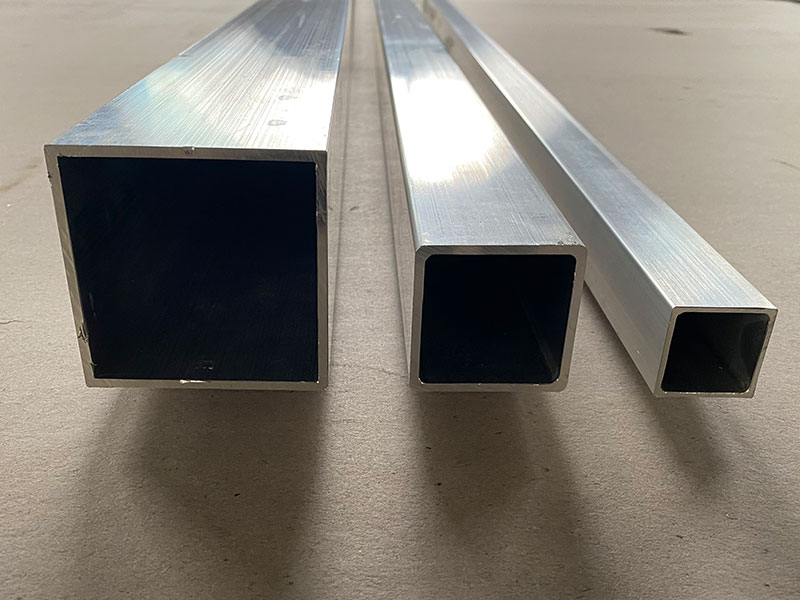

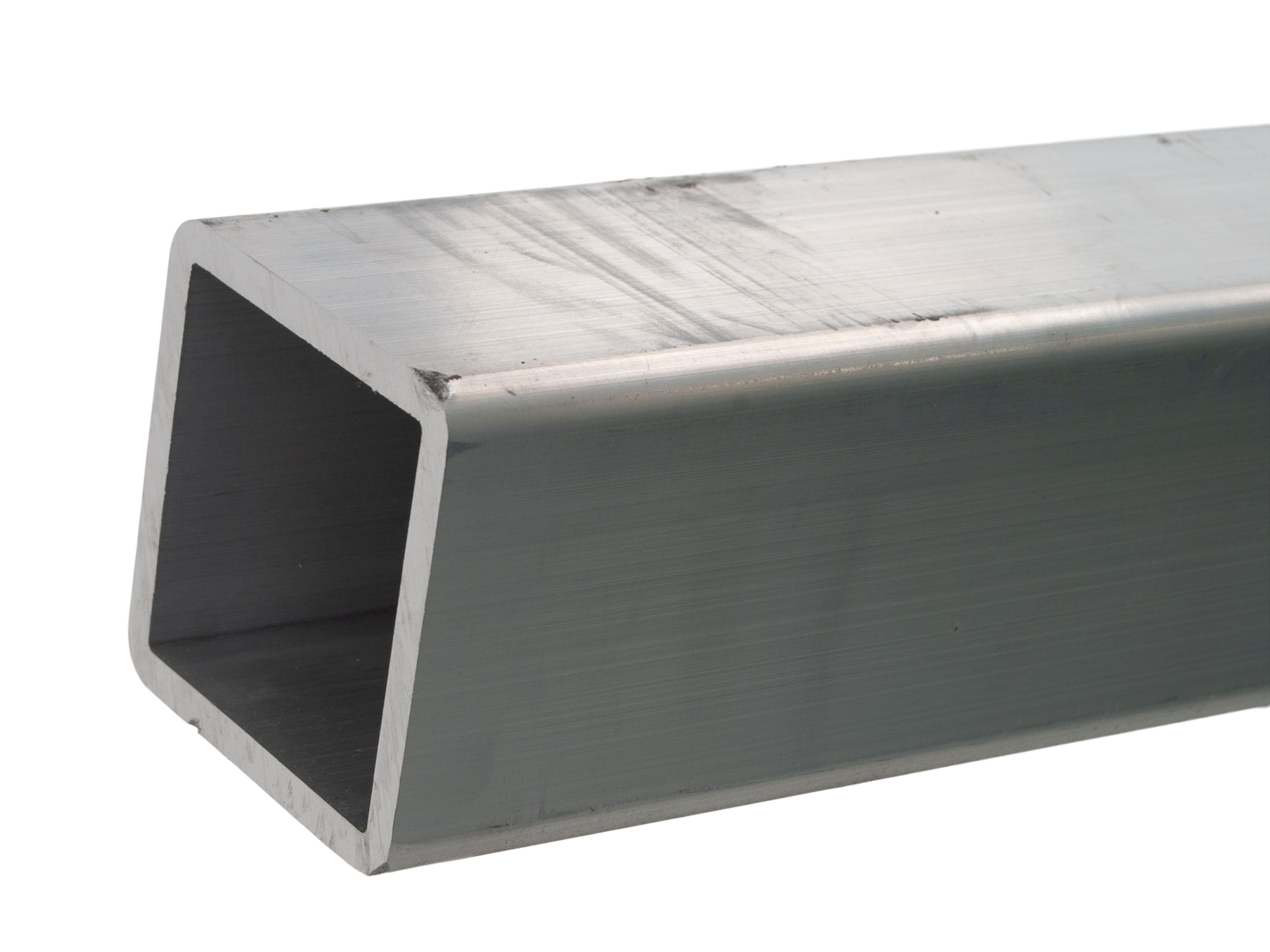

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

6061 Marine Aluminum Square Tubes for Yacht Construction

In the realm of yacht construction, materials play a pivotal role in defining vessel performance, durability, and aesthetics.

View Details6061 Marine Aluminum Tubes for Marine Engineering Projects

Marine engineering demands materials that combine exceptional strength, corrosion resistance, and versatility for reliable performance in harsh seawater environments.

View Details6061 Marine Aluminum Tubes for Custom Boat Frame Solutions

When it comes to constructing custom boat frames, marine-grade materials play a crucial role in ensuring longevity, safety, and performance. Among the vast selection of marine-grade metals.

View Details6061 Marine Aluminum Tubes for Custom Marine Construction

When it comes to building robust, lightweight, and corrosion-resistant structures for marine applications, 6061 Marine Aluminum Tubes unquestionably lead the pack.

View Details

Leave a Message