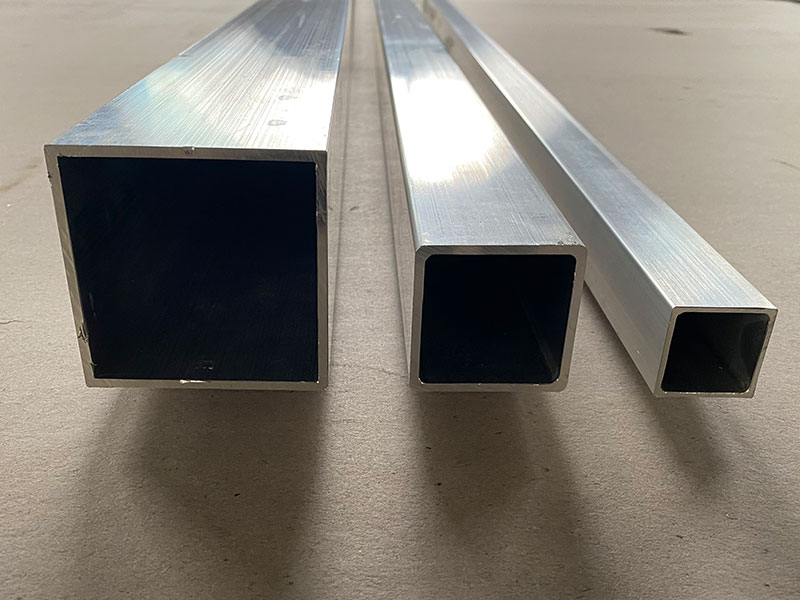

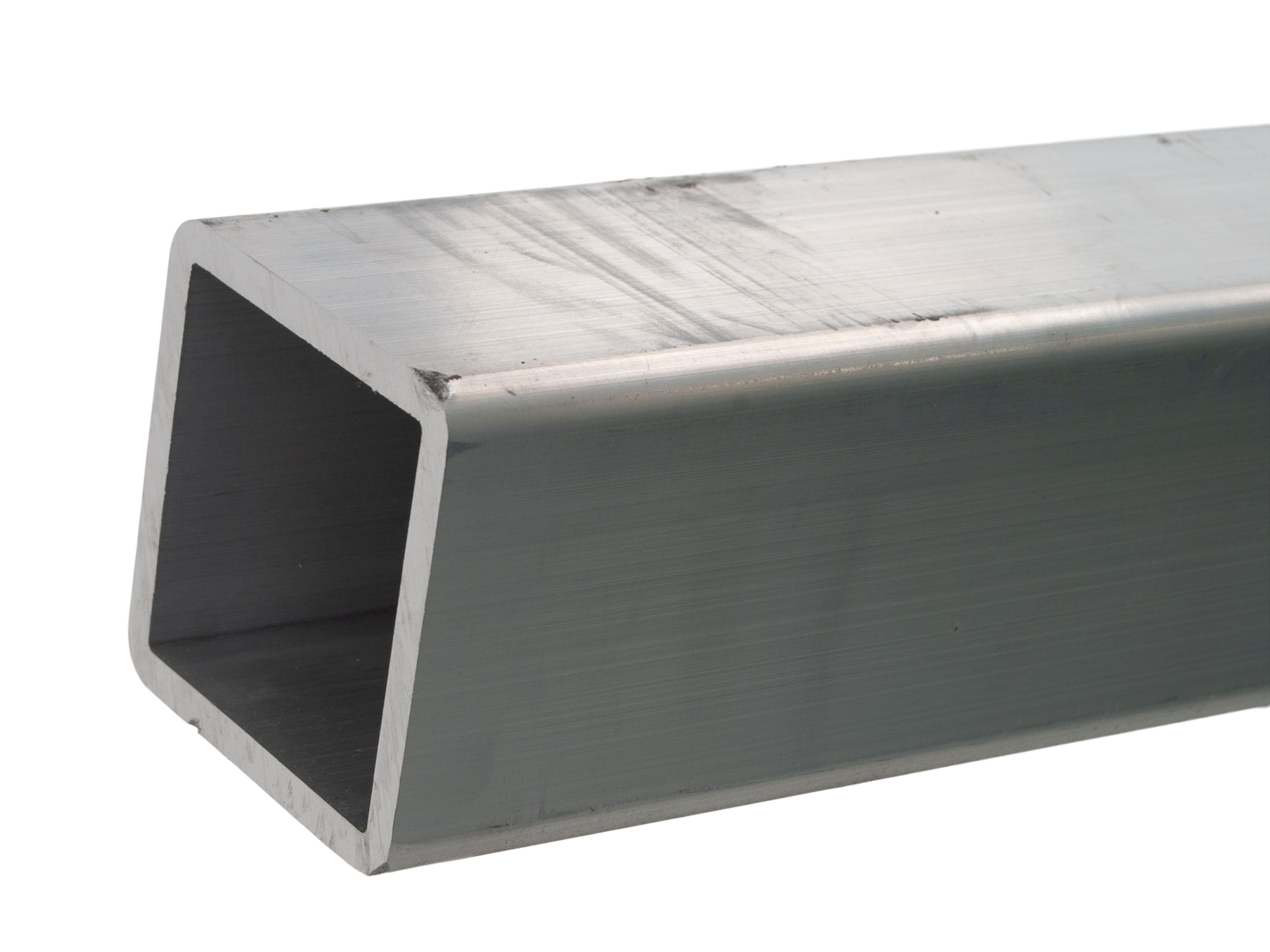

The 6061-T6 90-degree marine aluminum pipe elbow is an essential component designed specifically for marine applications requiring durability, corrosion resistance, and exceptional mechanical strength. Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

Marine environments are particularly demanding due to constant exposure to seawater and harsh weather conditions. The 6061-T6 aluminum alloy offers superior corrosion resistance combined with excellent mechanical performance, making it ideal for these challenging conditions. This 90-degree pipe elbow fitting allows for smooth and reliable directional changes in piping systems, promoting system integrity and longevity.

Features

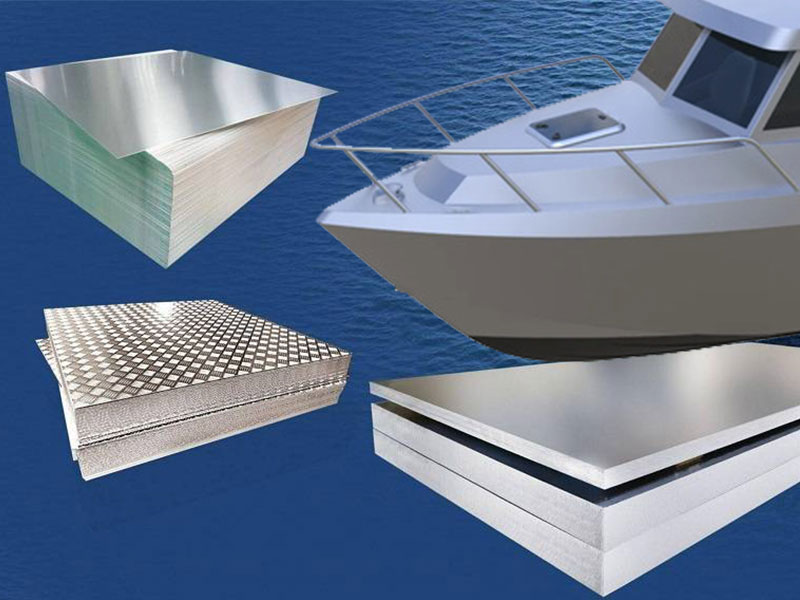

Material: 6061-T6 Marine-grade aluminum alloy

Angle: 90-degree elbow fitting for directional pipe changes

Corrosion Resistance: Excellent resistance to seawater corrosion and marine atmosphere

Mechanical Properties: High tensile strength and good fatigue resistance

Weight: Lightweight compared to steel, reducing installation and transportation costs

Surface Finish: Typically anodized or powder-coated for additional protection

Applications: Shipbuilding, offshore oil rigs, marine HVAC, water treatment facilities, and coastal infrastructure

Chemical Composition of 6061-T6 Alloy

| Element | Typical Percentage (%) |

|---|---|

| Aluminum (Al) | Balance |

| Silicon (Si) | 0.4 – 0.8 |

| Iron (Fe) | 0.7 max |

| Copper (Cu) | 0.15 – 0.40 |

| Manganese (Mn) | 0.15 max |

| Magnesium (Mg) | 0.8 – 1.2 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | 0.25 max |

| Titanium (Ti) | 0.15 max |

Mechanical and Physical Properties

| Property | Value | Unit |

|---|---|---|

| Ultimate Tensile Strength | 290 – 310 | MPa |

| Yield Strength (0.2% offset) | 240 – 275 | MPa |

| Elongation at Break | 8 – 12 | % |

| Modulus of Elasticity | 68.9 | GPa |

| Density | 2.7 | g/cm³ |

| Hardness (Brinell) | 95 – 110 | HB |

| Thermal Conductivity | 167 | W/m·K |

| Electrical Conductivity | 40 – 45 | % IACS |

Dimensional Specifications

| Nominal Pipe Size (NPS) | Outer Diameter (OD) | Wall Thickness | Center-to-End Dimensions | Weight (Approx.) |

|---|---|---|---|---|

| 1/2" | 21.3 mm | 2.77 mm | 28 mm | 0.05 kg |

| 3/4" | 26.7 mm | 2.87 mm | 31 mm | 0.08 kg |

| 1" | 33.4 mm | 3.38 mm | 38 mm | 0.12 kg |

| 1.5" | 48.3 mm | 3.68 mm | 44 mm | 0.25 kg |

| 2" | 60.3 mm | 3.91 mm | 57 mm | 0.45 kg |

Advantages in Marine Environments

Corrosion Resistance: 6061-T6 aluminum alloy forms a natural oxide layer that protects against oxidation and seawater damage, extending the lifespan of marine piping systems.

Lightweight: Aluminum weighs around one-third of steel, easing handling and installation, reducing vessel weight, and improving fuel efficiency.

Strength and Durability: The T6 temper enhances the pipe elbow’s mechanical properties, ensuring it withstands pressure, vibration, and mechanical stresses common in marine applications.

Thermal Performance: Excellent thermal conductivity helps dissipate heat in fluid systems, preventing localized damage and extending service life.

Fabrication and Welding: Good weldability ensures ease of integration into complex piping networks without compromising mechanical integrity.

Applications

Ship and yacht plumbing and fluid systems

Offshore and underwater pipeline systems

Cooling water and HVAC systems aboard marine vessels

Desalination and water treatment plants

Subsea pipelines and risers for oil and gas platforms

The 6061-T6 90-degree marine aluminum pipe elbow is a high-performance, corrosion-resistant fitting engineered for critical marine applications. Its combination of strength, durability, and lightweight construction makes it the preferred choice for shipbuilders and marine engineers aiming for long-lasting and reliable pipe systems. Whether used for seawater circulation systems, offshore platforms, or coastal infrastructure, this pipe elbow guarantees superior functionality under demanding marine conditions.

For customized sizes, surface treatments, or technical assistance, please contact our expert engineering team to discuss your specific marine aluminum pipe fitting needs.